You know the sound. That sudden grinding, a high-pitched squeal, and then… silence. The production line has ground to a halt. After a frantic diagnosis, the culprit is found: a tiny, inexpensive component—a PTFE bushing—has failed, seizing a critical piece of machinery. Again.

This scenario is a frustrating reality in many industrial, medical, and high-tech environments. A component that costs a few dollars has just cost you thousands in unplanned downtime.

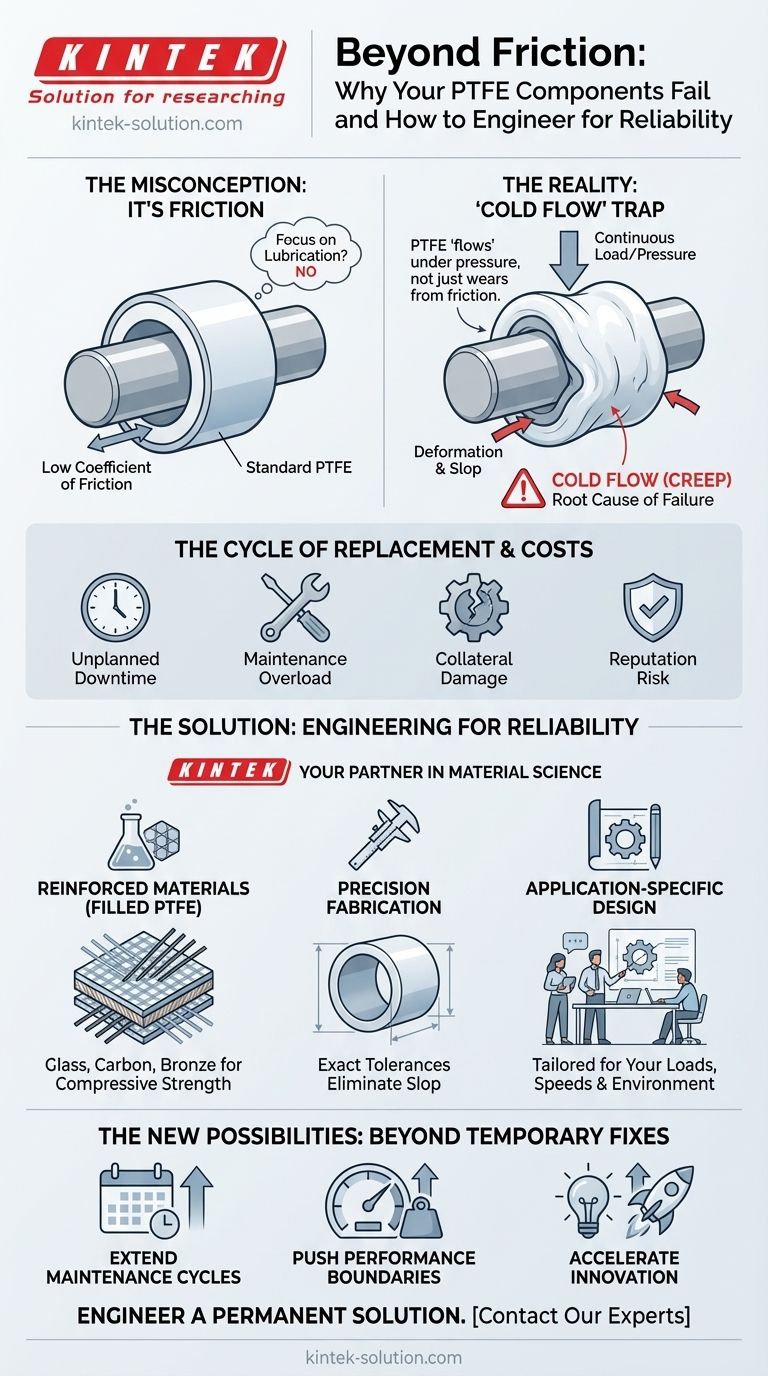

The Cycle of Replacement: Why 'More of the Same' Fails

When a bushing fails, the standard response is logical: replace it. You order an identical part, install it, and chalk the failure up to "normal wear and tear." Maybe you try a different lubricant, only to remember that PTFE is self-lubricating and shouldn't need it.

But a few months—or even weeks—later, you're right back where you started. The line is down, the same part has failed, and frustration is mounting.

This isn't just an engineering nuisance; it's a direct hit to the bottom line. The costs compound with every failure:

- Unplanned Downtime: Each hour the machine is offline represents lost production and missed revenue targets.

- Maintenance Overload: Your maintenance crews are pulled from preventative tasks to fight the same fire repeatedly, driving up labor costs.

- Collateral Damage: A failed bushing can quickly lead to scoring or damage on expensive shafts, housings, or motors, turning a small problem into a major repair.

- Reputation Risk: In industries like medical devices or semiconductors, component failure can lead to product recalls and a loss of customer trust.

Simply accepting this cycle as a cost of doing business is a critical mistake. The reason the replacement part keeps failing is that you're treating the symptom, not the disease.

The Root Cause: It’s Not Friction, It’s Physics

The problem often lies in a fundamental misunderstanding of the material itself. PTFE (Polytetrafluoroethylene) is famous for one thing: its incredibly low coefficient of friction. It's one of the slickest materials known to man. This makes it the default choice for any application requiring smooth, self-lubricating motion.

But this singular focus on low friction hides a critical trade-off that is the true source of your recurring failures.

The 'Cold Flow' Trap: When Low Friction Becomes a Liability

PTFE is a relatively soft polymer. Under continuous high loads, pressure, or even sustained high-velocity movement, the material can begin to deform, compress, and literally "flow" away from the high-stress area, even at room temperature. This phenomenon is known as cold flow or creep.

When your bushing "wears out," it's often not from friction in the traditional sense. Instead, the PTFE material has physically deformed under pressure, increasing the clearance, introducing slop into the system, and ultimately leading to catastrophic failure.

This is why the common solutions fail:

- Replacing with the same part: You are just restarting the clock on the same inevitable cold-flow failure.

- Focusing only on friction: You are optimizing for a variable that was never the root cause of the failure in your high-stress application.

The Solution: Engineering for the Application, Not Just the Spec Sheet

To truly solve this problem, you don't need a bushing with the absolute lowest friction. You need a component with the optimal balance of low friction and high mechanical durability for your specific operating conditions.

This requires moving beyond a simple material choice and into the realm of material engineering. The solution isn't to abandon PTFE, but to use a version of it that is intelligently designed to resist the forces causing it to fail.

KINTEK: Your Partner in Material Science, Not Just a Parts Supplier

At KINTEK, we specialize in fabricating PTFE components that are precisely engineered for their end-use. We understand that in a high-stress semiconductor handler, a medical pump, or an industrial actuator, a generic, off-the-shelf bushing is a liability waiting to happen.

We address the root cause of failure—cold flow—by creating custom-formulated and precision-machined PTFE components. This is how we do it:

- Reinforced Materials: For applications prone to creep, we utilize filled PTFE grades. By blending PTFE with materials like glass fiber, carbon, or bronze, we dramatically increase the material's compressive strength and resistance to cold flow. This maintains excellent low-friction properties while adding the structural integrity needed to survive high-stress environments.

- Precision Fabrication: A perfect material means nothing if the part's dimensions are wrong. Our expertise in precision production ensures every component meets your exact dimensional tolerances, eliminating the initial "slop" that can accelerate wear and deformation.

- Application-Specific Design: We don't just sell parts; we provide solutions. Our team works with you to understand your specific loads, speeds, and environmental challenges to recommend and fabricate a component that is truly fit-for-purpose, from a single prototype to high-volume production runs.

From Firefighting to Forward-Thinking: The New Possibilities

When you move from repeatedly replacing a failing component to installing one designed for longevity, the entire operational dynamic changes. You're no longer on the defensive.

Instead of planning for unexpected downtime, you can:

- Extend Maintenance Cycles: Service your equipment based on a predictable, reliable schedule, not emergency calls.

- Push Performance Boundaries: Increase the speed or load of your machinery with confidence, knowing its core components are robust enough to handle it.

- Accelerate Innovation: Design more ambitious, compact, and powerful products because you are no longer constrained by the durability limits of standard components.

Solving a recurring bushing failure is just the beginning. The real victory lies in building systems you can trust, pushing performance boundaries, and out-innovating your competition. Your material challenges are unique, and an off-the-shelf solution is rarely the optimal one. Our team of engineers specializes in translating your operational demands—from semiconductor cleanrooms to heavy industrial machinery—into precision-fabricated PTFE components that last. Let's move beyond temporary fixes and engineer a permanent solution for your most demanding projects. Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

Related Articles

- The PTFE Paradox: Why the 'Perfect' Material Fails—And How to Make It Work

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems

- Your "Inert" PTFE Component Might Be the Real Source of System Failure

- The Physics of a Perfect Fit: How PTFE Eliminates an Athlete's Hidden Distractions

- How PTFE Solves Critical Industrial Challenges Through Material Superiority