It’s a scenario no engineer wants to face. The new chemical processing line, which was supposed to be a showcase of efficiency, is down. A critical valve, specified to handle aggressive media, has failed just months into operation, causing a leak that halted production and raised serious safety concerns. The post-mortem reveals the grim truth: the "corrosion-resistant" valve has been eaten from the inside out.

Why did this happen? And more importantly, how can you prevent it from happening again?

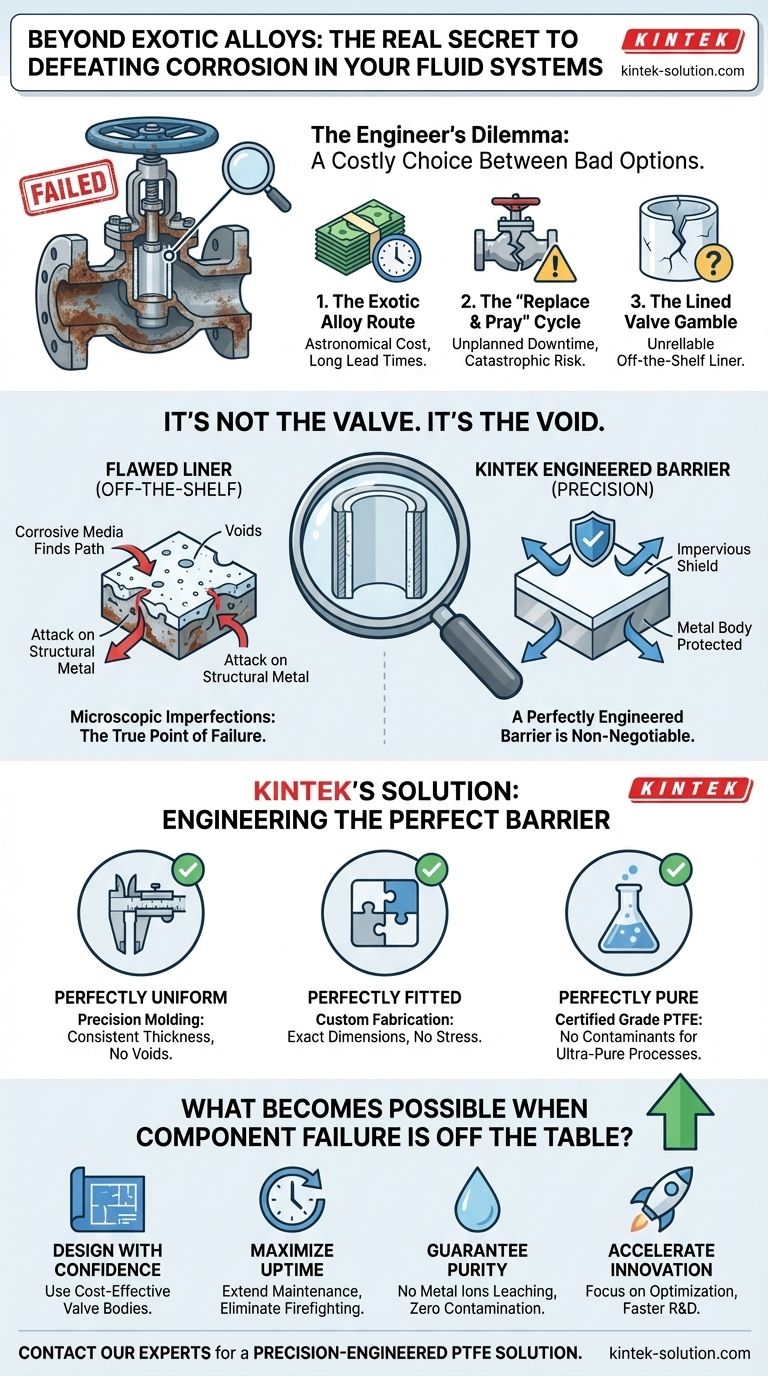

The Engineer's Dilemma: A Costly Choice Between Bad Options

If you manage fluid systems in demanding industries like semiconductor, chemical, or pharmaceutical manufacturing, this story is likely all too familiar. When faced with highly corrosive or ultra-pure fluids, you’re often pushed into a corner, forced to choose between a few imperfect strategies:

-

The Exotic Alloy Route: You specify valves made from expensive materials like Hastelloy or Titanium. While effective, the astronomical cost can cripple a project budget before it even begins, and long lead times can cause significant delays. It's the "sledgehammer" approach—powerful, but often overkill and financially unsustainable.

-

The "Replace and Pray" Cycle: You opt for standard stainless steel valves, fully accepting they will corrode. This treats valve failure as a routine maintenance cost. But the true price is paid in unplanned downtime, wasted labor, lost batches of product, and the constant risk of a catastrophic leak. It’s a reactive strategy that bleeds money and efficiency.

-

The Lined Valve Gamble: You try an off-the-shelf, PTFE-lined valve. It seems like the perfect compromise—the strength of steel with the resistance of PTFE. It works for a while, but then it fails unexpectedly, just like the standard valve. You conclude the technology is unreliable and revert to one of the other two costly options.

These choices all lead to the same negative business outcomes: inflated budgets, delayed projects, unreliable production, and unacceptable safety risks. But what if the entire premise of this dilemma is flawed? What if the real problem isn't the valve type, but a hidden factor that all three of these strategies overlook?

It’s Not the Valve. It’s the Void.

The critical turning point in understanding these failures is to stop focusing on the valve's metal body and start focusing on its protective shield.

Think of a lined valve like this: the outer metal body is the skeleton, providing the structural strength to handle system pressure. The internal PTFE liner is the skin—the seamless, non-negotiable barrier that keeps the corrosive "outside world" from ever touching the vulnerable skeleton.

The catastrophic failure of a lined valve almost never begins with the metal. It begins with a microscopic imperfection in that PTFE skin.

A tiny pinhole, an area of inconsistent thickness from poor molding, or a microscopic tear caused by an improper fit—these are the true points of failure. Once an aggressive chemical finds a path, no matter how small, it bypasses the liner and begins its silent, rapid attack on the structural metal. The valve is compromised from the inside, long before any external signs are visible.

This is why the "Lined Valve Gamble" so often fails. It assumes that all PTFE liners are created equal. They are not. An off-the-shelf liner, manufactured without obsessive attention to detail, is not a reliable barrier. It’s an accident waiting to happen. It treats a critical component as a commodity, and that is a recipe for failure.

From Commodity to Critical Component: Engineering the Perfect Barrier

To truly solve the corrosion problem cost-effectively, you don't just need a liner. You need a perfectly engineered barrier. This means a PTFE component that is:

- Perfectly Uniform: Manufactured with precision molding techniques to ensure consistent wall thickness, free from voids, pinholes, or weak spots.

- Perfectly Fitted: Custom-fabricated to the exact dimensions of the valve body, accounting for thermal expansion and pressure fluctuations to prevent stress and tearing.

- Perfectly Pure: Made from the correct, certified grade of PTFE, ensuring no contaminants will leach into an ultra-pure process (a non-negotiable for semiconductor and pharmaceutical applications).

This is not a component you can pick from a catalog. It must be engineered.

This is precisely where KINTEK's expertise provides the solution. We operate on the principle that the integrity of a PTFE component is not a feature; it is its entire purpose. We don't just manufacture PTFE parts; we engineer mission-critical barriers based on a deep understanding of why they fail.

Our precision production process is designed to eliminate the microscopic flaws that lead to catastrophic failure. Our custom fabrication capability means we don’t offer a one-size-fits-all solution; we build a liner or seal that is perfectly matched to your valve, your media, and your operating conditions—from a single prototype to high-volume production.

What Becomes Possible When Component Failure Is Off the Table?

When you shift your focus from buying a "valve" to engineering the "barrier," the persistent problems that plague your fluid systems simply disappear. By solving the liner integrity issue at its root, you unlock new levels of operational and financial performance.

- Design with Confidence: You can now use cost-effective carbon or stainless steel valve bodies in highly aggressive applications, knowing they are fully and reliably protected. Project budgets become manageable, and more projects become viable.

- Maximize Uptime: Unplanned downtime due to valve corrosion becomes a thing of the past. Maintenance cycles can be extended, and your team can focus on optimization instead of firefighting.

- Guarantee Purity: In industries where even parts-per-billion contamination can ruin a multi-million dollar batch of wafers or pharmaceuticals, you can be certain that no metal ions will ever leach into your process fluid.

- Accelerate Innovation: Instead of over-specifying and over-spending on exotic alloys "just in case," your R&D and process teams can move faster, knowing they have a reliable, cost-effective solution for fluid handling.

Your process is unique. The integrity of your system shouldn't rely on a generic, off-the-shelf component. If you're tired of making compromises between cost, safety, and reliability, it's time to solve the problem at its source. Let's talk about the specific demands of your project and how a precision-engineered PTFE solution can put an end to corrosion failures for good. Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

Related Articles

- The Physics of a Perfect Fit: How PTFE Eliminates an Athlete's Hidden Distractions

- The PTFE Paradox: Why the 'Perfect' Material Fails—And How to Make It Work

- The Unseen Guardian: How PTFE's Molecular Shield Protects Our Most Critical Systems

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault

- Your "Inert" PTFE Component Might Be the Real Source of System Failure