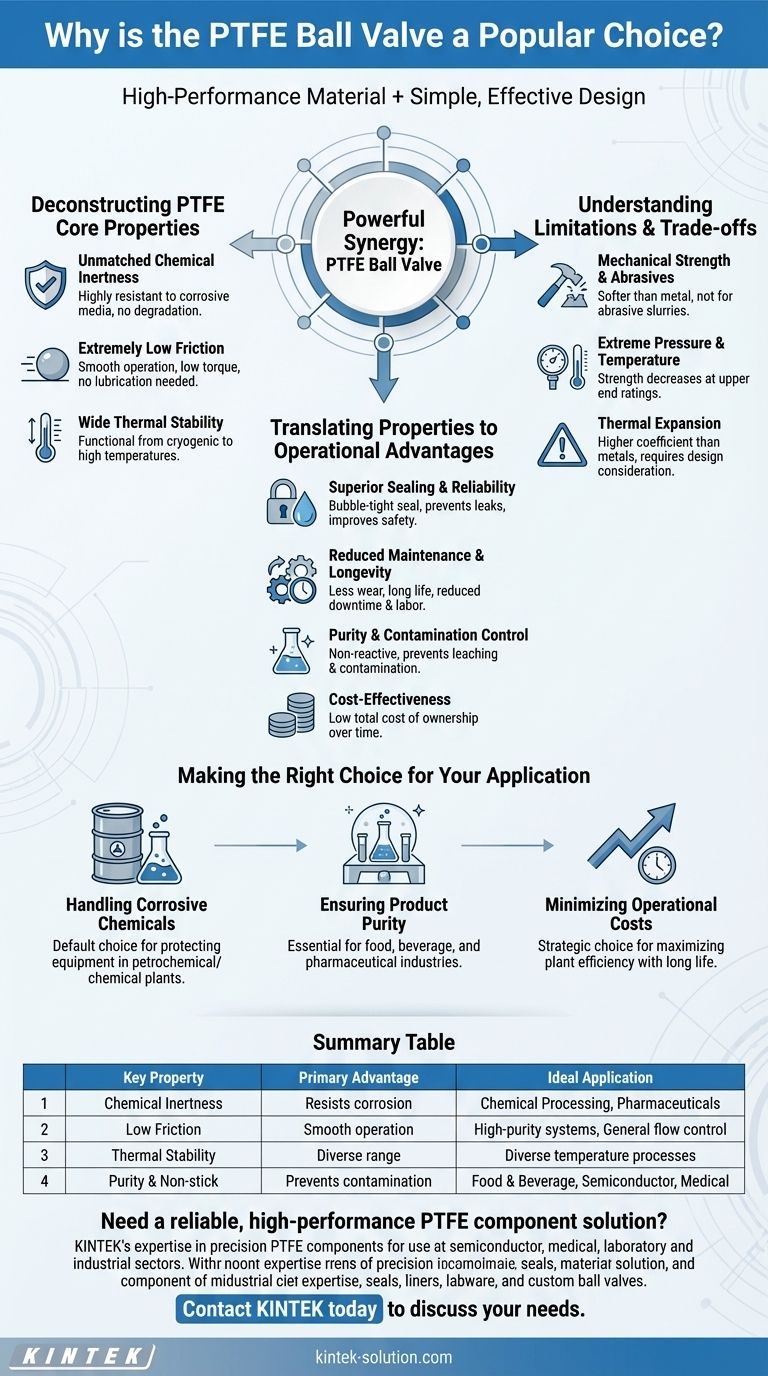

The popularity of the PTFE ball valve stems from its unique combination of high-performance material properties and a simple, effective mechanical design. In essence, it offers exceptional chemical resistance, a very low-friction surface, and stability across a wide temperature range. This makes it a highly reliable, durable, and low-maintenance choice for controlling flow in a vast number of industrial processes.

The true value of a PTFE ball valve isn't just one feature, but the powerful synergy of its properties. It simultaneously resists aggressive chemicals and extreme temperatures while ensuring smooth, low-maintenance mechanical operation, making it a uniquely versatile and reliable solution for controlling flow in demanding environments.

Deconstructing the Core Properties of PTFE

To understand why this valve is so widely adopted, we must first look at the material itself: Polytetrafluoroethylene (PTFE). Its fundamental characteristics are what provide the valve with its significant operational advantages.

Unmatched Chemical Inertness

PTFE is highly resistant to nearly all industrial chemicals and corrosive media. This inertness means the valve's internal components, particularly the seats and seals, will not degrade or corrode when exposed to harsh substances.

This property is critical in industries like chemical processing, pharmaceuticals, and fertilizers, where media can easily destroy less robust materials.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This creates an almost frictionless surface for the valve's ball to turn against the seat.

This characteristic is directly responsible for the valve's smooth operation, low torque requirements, and ability to function without any lubrication.

Wide Thermal Stability

The material remains stable and functional across an impressive range of temperatures. It doesn't become brittle at low temperatures or degrade at high temperatures common in many industrial processes.

This allows a single type of valve to be specified for diverse applications, from cryogenic services to heated processing lines.

Translating Properties into Operational Advantages

These core material properties translate directly into tangible benefits for engineers, operators, and plant managers. The design of a ball valve perfectly leverages what PTFE has to offer.

Superior Sealing and Reliability

The low-friction nature of PTFE allows the ball to create a bubble-tight seal against the seats with minimal force, or "torque." This ensures a reliable shutoff, preventing leaks and improving process safety and efficiency.

Reduced Maintenance and Longevity

Because PTFE is self-lubricating and resistant to chemical attack, the valve experiences significantly less wear and tear. This results in a long, maintenance-free service life, which reduces downtime and labor costs.

Purity and Contamination Control

In industries like food, beverage, and pharmaceuticals, process purity is non-negotiable. PTFE's chemical inertness ensures that the valve material does not leach into or react with the process media, preventing contamination.

Cost-Effectiveness

While not always the cheapest option upfront, PTFE ball valves offer a low total cost of ownership. Their durability, simple installation, and minimal maintenance needs make them a highly economical choice over the long term compared to more exotic or high-maintenance alternatives.

Understanding the Limitations and Trade-offs

Despite its versatility, the PTFE ball valve is not the universal solution for every application. Being an objective advisor means acknowledging its limitations.

Mechanical Strength and Abrasives

PTFE is a polymer, meaning it is inherently softer than metal. It is generally not suitable for services containing abrasive particles or slurries, which can quickly erode the soft seats and compromise the seal.

Extreme Pressure and Temperature Combinations

While it has a wide temperature range, PTFE's mechanical strength can decrease at the upper end of its temperature and pressure ratings. In extremely high-pressure, high-temperature applications, a metal-seated valve might be a more robust choice.

Thermal Expansion

Like all plastics, PTFE has a higher coefficient of thermal expansion than metals. In applications with rapid and extreme temperature cycling, this must be accounted for in the valve's design to prevent sealing issues.

Making the Right Choice for Your Application

Selecting the correct valve is about matching its capabilities to your primary operational goal.

- If your primary focus is handling corrosive chemicals: PTFE's inertness makes it the default choice for protecting equipment integrity and preventing dangerous leaks in petrochemical and chemical processing plants.

- If your primary focus is ensuring product purity: The non-reactive, non-stick surface of PTFE is essential for applications in the food, beverage, and pharmaceutical industries where contamination is unacceptable.

- If your primary focus is minimizing operational costs: The long, maintenance-free service life and reliability of PTFE ball valves reduce downtime and labor, making them a strategic choice for maximizing plant efficiency.

Ultimately, selecting a PTFE ball valve is a strategic decision for achieving reliability and efficiency in demanding industrial environments.

Summary Table:

| Key Property | Primary Advantage | Ideal Application |

|---|---|---|

| Chemical Inertness | Resists corrosion from harsh media | Chemical Processing, Pharmaceuticals |

| Low Friction | Smooth operation, no lubrication needed | High-purity systems, General flow control |

| Thermal Stability | Performs from cryogenic to high temperatures | Diverse temperature processes |

| Purity & Non-stick | Prevents contamination, easy cleaning | Food & Beverage, Semiconductor, Medical |

Need a reliable, high-performance PTFE component solution?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, labware, and custom ball valves—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment benefits from unmatched chemical resistance, purity, and durability.

Whether you require a standard part or a custom fabrication from prototype to high-volume production, we are committed to delivering quality that enhances your process efficiency and reduces total cost of ownership.

Contact KINTEK today to discuss your specific application needs and discover how our PTFE solutions can solve your most challenging flow control problems.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the key features of Teflon balls? Unlock Superior Performance in Demanding Environments

- What are the common applications of PTFE balls? Leverage Unmatched Chemical Resistance & Low Friction

- What are the properties of Teflon balls? Unlock Elite Chemical & Friction Resistance

- What industries commonly use PTFE balls? Essential for Chemical, Pharma, and Food Processing

- What are the tolerances for PTFE balls based on size? Precision vs. Standard Grade Explained