At its core, Teflon is used in high-performance applications because it possesses a rare combination of three elite properties that most other materials cannot offer simultaneously. It has an exceptionally low coefficient of friction, is almost completely inert to chemical attack, and remains stable across an extremely wide range of temperatures. This triad makes it a default choice for environments where reliability under multiple, simultaneous stresses is non-negotiable.

The true value of Teflon (PTFE) isn't just one of its famous traits, but its ability to maintain all of its high-performance characteristics—low friction, chemical resistance, and thermal stability—even when exposed to extreme conditions that would cause conventional materials to fail.

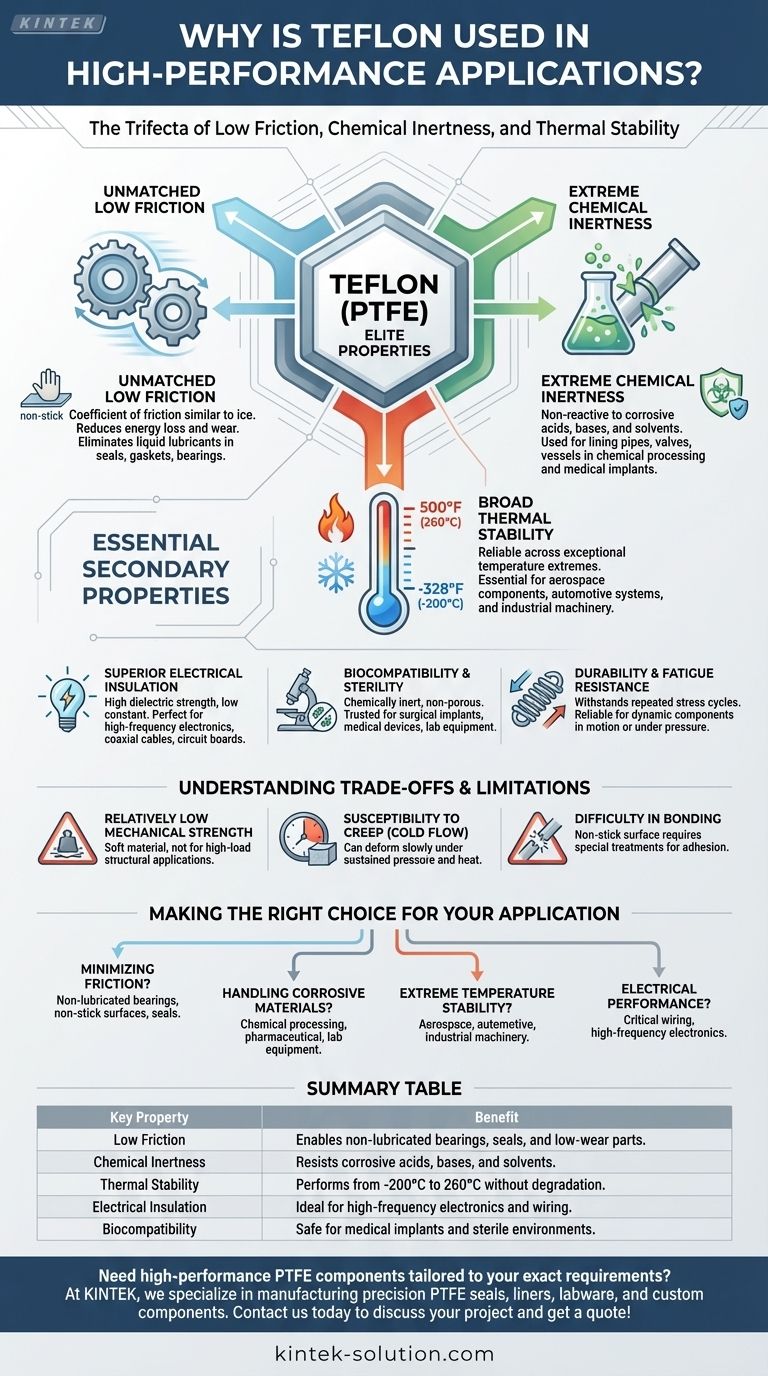

The Trifecta of High-Performance Properties

The material's reputation is built on three foundational pillars. Understanding how these properties interact is key to understanding its value in aerospace, chemical, and medical fields.

Unmatched Low Friction

Teflon, or Polytetrafluoroethylene (PTFE), has one of the lowest coefficients of friction of any known solid material. This gives it a "non-stick" or anti-adhesive quality that is critical for performance.

In mechanical systems, this means parts like seals, gaskets, and bearings can operate with minimal energy loss and wear. This property reduces the need for liquid lubricants, simplifying design and reducing maintenance in demanding machinery.

Extreme Chemical Inertness

Teflon is non-reactive to a vast array of corrosive substances, including aggressive acids and bases. This chemical stability is fundamental to its use in demanding industrial environments.

It is used to line pipes, valves, and vessels in chemical processing plants where it protects components from degradation. In medical applications, this inertness ensures that implants or surgical tools will not react with bodily tissues or fluids.

Broad Thermal Stability

The material performs reliably across an exceptional temperature range, from cryogenic lows of -328°F (-200°C) to high-heat environments of 500°F (260°C).

This stability allows it to be used in aerospace applications where components face extreme temperature swings, as well as in automotive systems and industrial machinery where high operating temperatures are common.

Essential Secondary Properties for Demanding Roles

Beyond the core three, several other characteristics make Teflon an ideal choice for specific, high-stakes applications.

Superior Electrical Insulation

Teflon exhibits a high dielectric strength and a low dielectric constant. This means it is an excellent electrical insulator that doesn't store electrical energy.

These properties are crucial for high-frequency electronics, like coaxial cables and circuit boards, where preserving signal integrity and preventing electrical interference is paramount.

Biocompatibility and Sterility

Because it is chemically inert and non-porous, Teflon is highly biocompatible. The material can be sterilized and does not support bacterial growth, making its surface easy to clean.

This makes it a trusted material for surgical implants, medical devices, and laboratory equipment where hygiene and preventing contamination are critical safety requirements.

Durability and Fatigue Resistance

While not as hard as metal, Teflon has excellent fatigue resistance. It can withstand repeated cycles of stress without failing.

This makes it a reliable choice for dynamic components like seals and machinery parts that are constantly in motion or under pressure.

Understanding the Trade-offs and Limitations

No material is perfect, and being a trusted advisor means acknowledging where Teflon may not be the right choice. Its unique strengths come with inherent trade-offs.

Relatively Low Mechanical Strength

Compared to engineering plastics or metals, Teflon is a relatively soft material. It is not suitable for high-load structural applications where rigidity and tensile strength are the primary requirements.

Susceptibility to Creep

Under sustained pressure, especially at elevated temperatures, Teflon can be prone to "creep" or cold flow. This means it can slowly deform over time, which must be accounted for in the design of high-pressure seals and gaskets.

Difficulty in Bonding

Teflon's low-friction, non-stick surface makes it very difficult to bond to other materials using conventional adhesives. While special surface treatments can overcome this, it adds complexity and cost to the manufacturing process.

Making the Right Choice for Your Application

Selecting Teflon is about matching its unique profile to a specific operational challenge.

- If your primary focus is minimizing friction: Its incredibly low coefficient of friction makes it the premier choice for non-lubricated bearings, non-stick surfaces, and low-resistance seals.

- If your primary focus is handling corrosive materials: Its near-total chemical inertness is the key factor for use in chemical processing, pharmaceutical, and laboratory equipment.

- If your primary focus is extreme temperature stability: Its ability to perform from cryogenic conditions to high heat makes it ideal for aerospace, automotive, and demanding industrial machinery.

- If your primary focus is electrical performance: Its properties as a high-grade insulator are why it's used in critical wiring and high-frequency electronics.

Ultimately, Teflon is the solution for high-performance problems where multiple extreme conditions exist and singular material failure is not an option.

Summary Table:

| Key Property | Benefit for High-Performance Applications |

|---|---|

| Low Friction | Enables non-lubricated bearings, seals, and low-wear parts. |

| Chemical Inertness | Resists corrosive acids, bases, and solvents. |

| Thermal Stability | Performs from -200°C to 260°C without degradation. |

| Electrical Insulation | Ideal for high-frequency electronics and wiring. |

| Biocompatibility | Safe for medical implants and sterile environments. |

Need high-performance PTFE components tailored to your exact requirements?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, our expertise ensures your parts meet the highest standards for chemical resistance, thermal stability, and durability.

Contact us today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability