At its core, Teflon is used in electrical applications because it is an exceptional electrical insulator. Its true value, however, comes from a unique combination of properties that allow it to maintain this insulating capability under extreme conditions where other materials would fail. This includes high dielectric strength, outstanding resistance to heat and chemicals, and non-flammability, making it a critical material for demanding electronic and high-voltage systems.

While many materials can insulate electricity, Teflon (PTFE) is chosen for critical applications where high temperatures, corrosive chemicals, and high voltages would cause lesser insulators to degrade or fail. Its defining advantage is unwavering reliability under a multitude of environmental stresses.

The Foundational Electrical Properties

Teflon’s primary role in any electrical system is to prevent the flow of current where it is not wanted. It accomplishes this with a set of electrical characteristics that are nearly ideal for insulation.

Unpacking High Dielectric Strength

Dielectric strength is a measure of a material's ability to withstand a high voltage before it breaks down and conducts electricity.

Teflon possesses a very high dielectric strength. This makes it an essential material for insulating wires, connectors, and components in high-voltage equipment, ensuring that the electrical charge remains contained.

Superior Electrical Insulation

Beyond withstanding high voltage, Teflon is an excellent insulator in a general sense, meaning it strongly resists the flow of electric current.

This property is fundamental to preventing short circuits, protecting sensitive electronic components from interference, and ensuring the safety and efficiency of the overall system.

Stability Across Frequencies

Teflon’s electrical properties remain remarkably stable across a wide range of frequencies.

This makes it particularly valuable in high-frequency applications, such as in coaxial cables for telecommunications and components for radar systems, where signal integrity is paramount.

Why Thermal Resistance is a Game-Changer

Electrical components often generate significant heat. An insulating material is useless if it melts, deforms, or burns when the system operates at its intended capacity.

A Vast Operating Temperature Range

Teflon maintains its structural integrity and insulating properties across an incredibly wide temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This allows it to be used in everything from cryogenic applications to high-heat aerospace and industrial components without degrading its performance.

Non-Flammability for Safety

Safety is a critical concern in electrical design. Teflon is non-flammable, meaning it will not ignite or contribute to the spread of a fire.

This is a vital safety feature, especially in aerospace, automotive, and industrial equipment where an electrical fire could have catastrophic consequences.

The Role of Chemical and Environmental Immunity

In many advanced applications, electrical components are not isolated in a clean, stable environment. They are often exposed to chemicals, moisture, and other corrosive elements.

Unrivaled Chemical Inertness

Teflon is famously inert, meaning it does not react with most chemicals, including aggressive acids, solvents, and bases.

This property is crucial in semiconductor manufacturing and chemical processing plants, where insulating components must function reliably while being exposed to a hostile chemical environment.

Resistance to Moisture and UV

Unlike many other plastics, Teflon does not absorb water and is highly resistant to degradation from UV radiation.

This makes it an ideal insulator for outdoor applications or in equipment where moisture is present, as its electrical properties will not be compromised by environmental exposure.

Understanding the Trade-offs

No material is perfect for every situation. While Teflon’s properties are exceptional, its limitations are important to understand for proper material selection.

Mechanical Limitations

Teflon is a relatively soft material with lower tensile strength compared to many engineering plastics. It can be susceptible to "creep" or cold flow, meaning it can deform over time when subjected to a sustained load.

Processing and Cost

Teflon cannot be processed using conventional, high-volume methods like injection molding. It is most often machined from stock shapes (rods, sheets), which can be a more expensive and slower manufacturing process. This higher cost reserves it for applications where its unique benefits are truly necessary.

Making the Right Choice for Your Application

Selecting the right insulator requires balancing performance requirements with cost and manufacturability.

- If your primary focus is high-voltage insulation in a harsh environment: Teflon's combination of dielectric strength, chemical inertness, and thermal stability is nearly unmatched.

- If your primary focus is standard insulation for low-cost consumer electronics: A more conventional and easily-moldable polymer is likely a more practical and cost-effective choice.

- If your application demands both structural strength and electrical insulation: You may need to consider a reinforced grade of Teflon or a different engineering plastic that offers a better balance of mechanical and electrical properties.

Ultimately, Teflon is the material of choice when electrical insulation cannot be compromised by heat, chemicals, or environmental stress.

Summary Table:

| Key Property | Benefit for Electrical Applications |

|---|---|

| High Dielectric Strength | Withstands high voltages, preventing electrical breakdown in critical components. |

| Extreme Temperature Resistance | Maintains integrity from -200°C to +260°C, ideal for aerospace, automotive, and industrial uses. |

| Superior Chemical Inertness | Resists corrosive acids and solvents, ensuring reliability in semiconductor and chemical processing. |

| Non-Flammable | Enhances safety by not igniting or contributing to fire spread in high-risk environments. |

| Low Moisture Absorption | Prevents degradation and maintains stable insulation properties in humid or outdoor conditions. |

Need Reliable PTFE Components for Your Demanding Application?

When failure is not an option, you need a supplier who understands the critical balance of precision, performance, and durability. KINTEK specializes in manufacturing high-quality PTFE components—including custom seals, liners, and labware—for the most challenging environments in the semiconductor, medical, laboratory, and industrial sectors.

We offer custom fabrication from prototypes to high-volume orders, ensuring your components meet exact specifications for dielectric strength, thermal stability, and chemical resistance.

Let's discuss how our precision PTFE solutions can enhance the safety and reliability of your electrical systems. Contact our experts today for a consultation.

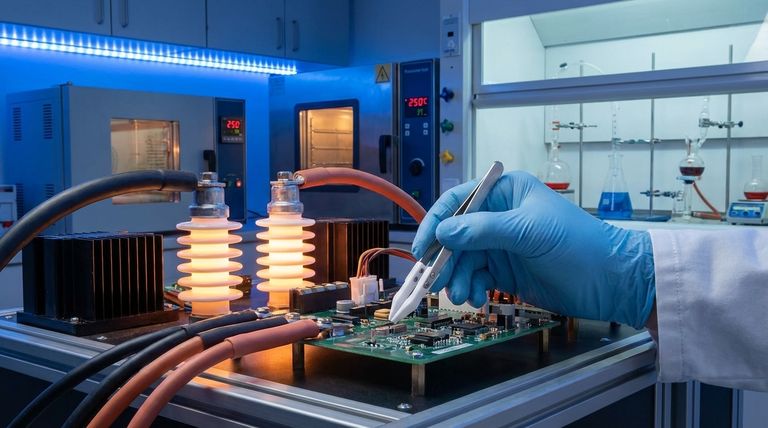

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability