In short, Teflon is highly suitable for food processing because its unique combination of properties directly addresses the industry's most critical demands: hygiene, safety, and operational efficiency. Its non-stick surface simplifies cleaning, its chemical inertness prevents contamination from food or cleaning agents, and its non-toxic nature ensures it complies with strict food safety standards.

The core reason for Teflon's prevalence is not just one feature, but its holistic performance. It simultaneously prevents product adhesion, resists chemical corrosion from both ingredients and sanitizers, and maintains its integrity under thermal stress, making it a uniquely reliable material for food-contact applications.

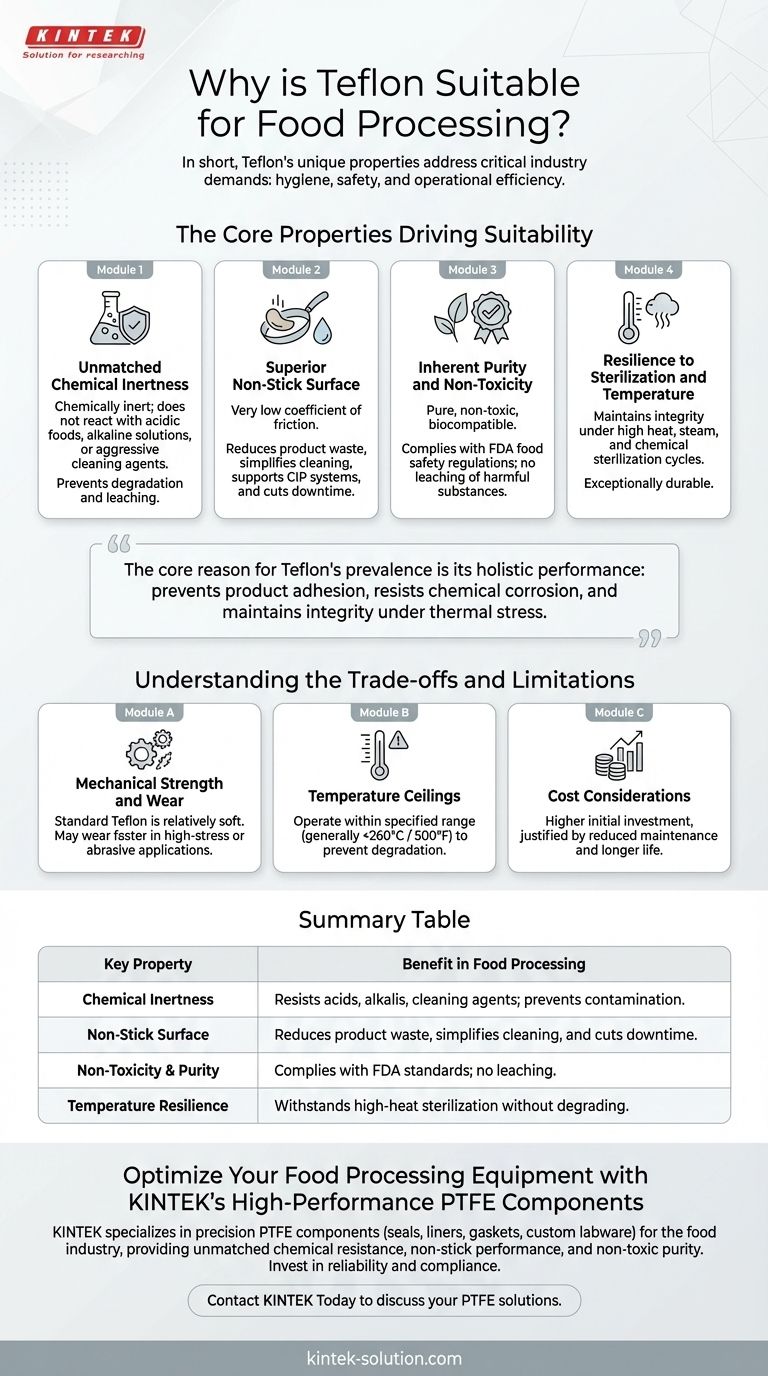

The Core Properties Driving Suitability

To understand why Teflon (PTFE) is a default choice in food processing, we must analyze the specific properties that solve the industry's primary challenges.

Unmatched Chemical Inertness

Teflon is one of the most chemically inert polymers known. This means it does not react with the vast majority of chemicals.

In a food processing environment, this is critical. It ensures that the material will not degrade or leach substances when in contact with acidic foods (like tomato sauces), alkaline solutions, or aggressive industrial cleaning and sterilization agents.

Superior Non-Stick Surface

The famous non-stick quality of Teflon is due to its very low coefficient of friction. Food products, viscous liquids, and powders slide off its surface with ease.

This property dramatically reduces product waste and significantly cuts down on cleaning time and effort. Equipment can be cleaned more quickly and thoroughly, supporting efficient Clean-in-Place (CIP) systems and reducing operational downtime.

Inherent Purity and Non-Toxicity

Teflon is an inherently pure and non-toxic material. It is biocompatible and does not require plasticizers or other additives that could potentially leach into food products over time.

This characteristic is fundamental for compliance with food safety regulations, such as those from the FDA. It guarantees that the material itself will not become a source of contamination.

Resilience to Sterilization and Temperature

Food processing equipment must withstand frequent and rigorous sterilization cycles, which often involve high heat, steam, or chemical agents.

Teflon maintains its structural integrity and performance characteristics across a wide temperature range, making it exceptionally durable against common sterilization methods.

Understanding the Trade-offs and Limitations

While highly effective, Teflon is not the solution for every single application. Acknowledging its limitations is key to using it correctly.

Mechanical Strength and Wear Resistance

Standard Teflon is a relatively soft material. In applications involving high mechanical stress or significant abrasive friction (like scraping against hard particles), it can wear more quickly than harder plastics or metals.

For these high-wear scenarios, filled grades of Teflon (mixed with glass, carbon, or other agents) are often used to enhance durability, but this requires careful selection to maintain food-safe status.

Temperature Ceilings

Although Teflon has an excellent operational temperature range, it has its limits. At extremely high temperatures (generally above 500°F or 260°C), it can begin to degrade.

It is crucial to operate within the material's specified temperature range to ensure both safety and performance.

Cost Considerations

Teflon is a high-performance polymer, and its cost is typically higher than that of commodity plastics like polyethylene or polypropylene.

The initial investment, however, is often justified by reduced maintenance, longer equipment life, and improved operational efficiency.

Making the Right Choice for Your Application

Selecting the right material requires aligning its properties with your primary operational goal.

- If your primary focus is hygiene and rapid cleaning: Teflon's non-stick and non-porous surface is an ideal choice for coatings, liners, and conveyor belts.

- If your primary focus is chemical compatibility: For handling aggressive ingredients or harsh sanitation chemicals, Teflon seals, gaskets, and tubing provide unmatched reliability.

- If your primary focus is durability in a high-abrasion setting: You should evaluate whether standard Teflon is sufficient or if a food-grade, filled-PTFE compound is necessary to prevent premature wear.

Ultimately, choosing Teflon is an investment in operational safety, purity, and long-term efficiency for your food processing system.

Summary Table:

| Key Property | Benefit in Food Processing |

|---|---|

| Chemical Inertness | Resists acids, alkalis, and cleaning agents; prevents contamination. |

| Non-Stick Surface | Reduces product waste, simplifies cleaning, and cuts downtime. |

| Non-Toxicity & Purity | Complies with FDA standards; no leaching of harmful substances. |

| Temperature Resilience | Withstands high-heat sterilization cycles without degrading. |

Optimize Your Food Processing Equipment with KINTEK's High-Performance PTFE Components

Choosing the right material is critical for the safety, efficiency, and longevity of your food processing operations. At KINTEK, we specialize in manufacturing precision PTFE (Teflon) components—including seals, liners, gaskets, and custom labware—that are engineered to meet the rigorous demands of the food industry.

Our components provide the unmatched chemical resistance, non-stick performance, and non-toxic purity your application requires. Whether you need a standard part or a custom-fabricated solution for a high-abrasion or high-temperature environment, we can deliver from prototype to high-volume production.

Invest in reliability and compliance. Contact KINTEK today to discuss how our PTFE solutions can enhance your food processing systems.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments