The suitability of PTFE for the automotive industry, particularly for electric vehicles (EVs), stems from its unique combination of four key properties: extreme temperature resistance, chemical inertness, low friction, and excellent electrical insulation. These characteristics allow it to solve critical engineering challenges in high-performance environments, from traditional engines to the specialized demands of EV batteries and high-speed motors.

The core reason for PTFE's value is its multifaceted performance under stress. While other materials may excel in one area, PTFE delivers a robust combination of thermal, chemical, electrical, and mechanical properties that are essential for the reliability and safety of modern vehicles, especially EVs.

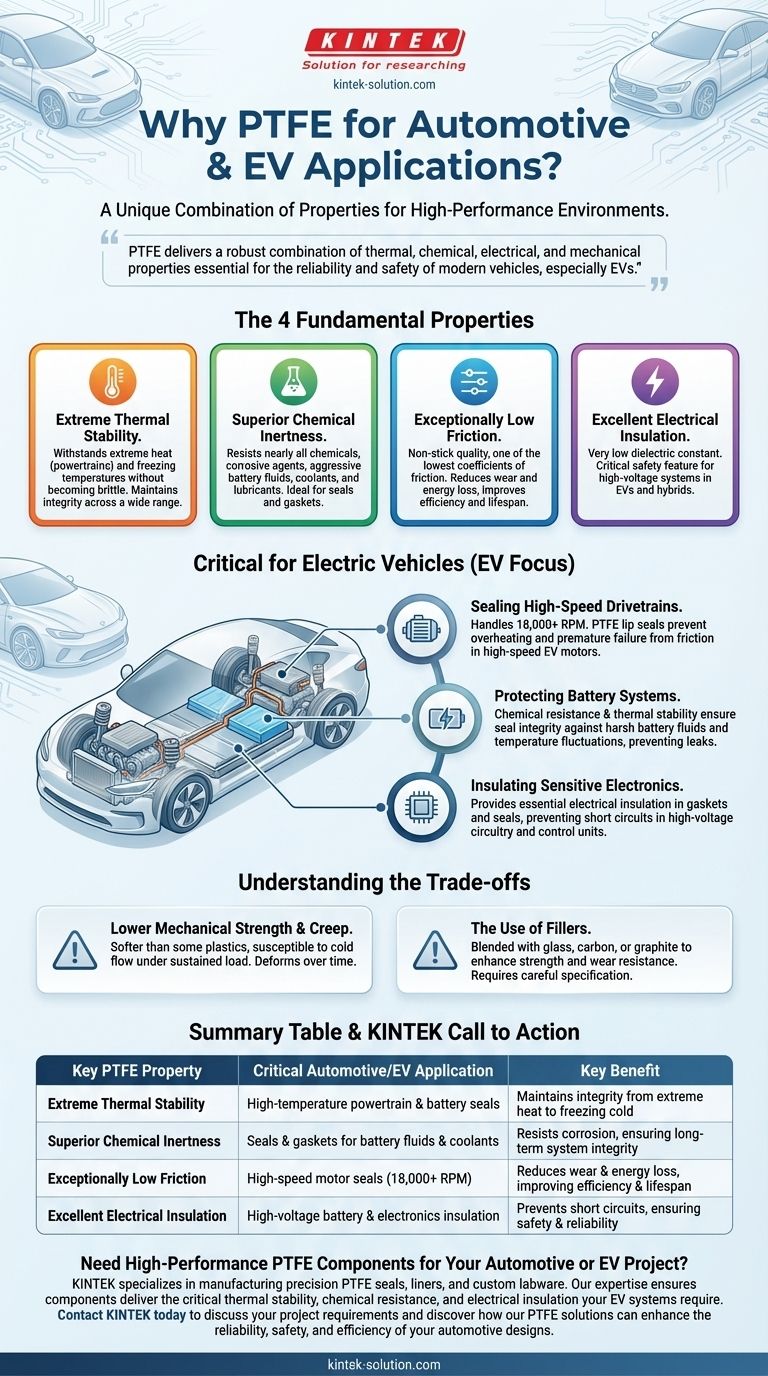

The Fundamental Properties Driving Adoption

To understand PTFE's role, we must first examine its inherent material characteristics. These properties are not just beneficial; they are often requirements for components operating under extreme conditions.

Unmatched Thermal Stability

PTFE maintains its structural integrity and performance across an exceptionally wide temperature range. It can withstand both the extreme heat generated by powertrains and the freezing temperatures of harsh climates without becoming brittle or degrading.

Superior Chemical Inertness

This material is famously resistant to nearly all chemicals and corrosive agents. This makes it an ideal choice for seals and gaskets that come into contact with aggressive battery fluids, coolants, and lubricants.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, giving it a non-stick quality. In moving parts, this property dramatically reduces wear and energy loss, which directly translates to improved efficiency and longer component life.

Excellent Electrical Insulation

As a material with a very low dielectric constant, PTFE is a superb electrical insulator. This is a critical safety and performance feature in the high-voltage systems of electric and hybrid vehicles.

Why These Properties are Critical for Electric Vehicles

While valuable in all vehicles, PTFE's properties are uniquely suited to solve the intensified challenges presented by electric vehicle architecture.

Sealing High-Speed Drivetrains

EV motors operate at much higher rotational speeds than internal combustion engines, often exceeding 18,000 RPM. PTFE lip seals are one of the few materials that can handle these high shaft speeds without overheating or premature failure due to friction.

Protecting Battery Systems

The enclosures for high-voltage battery packs require seals that can withstand harsh chemical environments and temperature fluctuations. PTFE’s chemical resistance and thermal stability ensure the integrity of these critical seals, protecting the battery from external contaminants and preventing leaks.

Insulating Sensitive Electronics

EVs are packed with sensitive electronic components and high-voltage circuitry. PTFE's use in gaskets and seals provides essential electrical insulation, preventing short circuits and ensuring the reliability of control units and power systems.

Understanding the Trade-offs

No material is perfect, and a complete technical assessment requires acknowledging limitations. Objectivity is key when selecting materials for critical applications.

Lower Mechanical Strength

Compared to some engineering plastics, PTFE is softer and has lower tensile strength. It can be susceptible to "creep" or cold flow under sustained load, meaning it can deform over time.

The Use of Fillers

To counteract its mechanical limitations, PTFE is often blended with fillers like glass, carbon, or graphite. While these additives enhance strength and wear resistance, they can also slightly alter other properties, such as its coefficient of friction or chemical compatibility. This requires careful consideration during material specification.

Making the Right Choice for Your Application

Selecting PTFE is about matching its specific strengths to a clear engineering goal. Your application's primary demand will determine if it's the optimal choice.

- If your primary focus is high-speed rotational sealing: PTFE is a leading candidate due to its low friction at extreme RPMs, making it ideal for EV motor seals.

- If your primary focus is battery or chemical containment: Its unmatched chemical inertness makes it the default choice for gaskets and seals in aggressive fluid environments.

- If your primary focus is electrical isolation in a demanding environment: PTFE's dielectric properties combined with its thermal stability offer a reliable solution for sealing high-voltage components.

- If your primary focus is improving mechanical efficiency: PTFE coatings or components are excellent for reducing friction in bearings and piston rings, enhancing the fuel economy and lifespan of conventional engines.

Understanding PTFE's specific strengths allows engineers to design more efficient, reliable, and safer systems for the next generation of vehicles.

Summary Table:

| Key PTFE Property | Critical Automotive/EV Application | Key Benefit |

|---|---|---|

| Extreme Thermal Stability | High-temperature powertrain & battery seals | Maintains integrity from extreme heat to freezing cold |

| Superior Chemical Inertness | Seals & gaskets for battery fluids & coolants | Resists corrosion, ensuring long-term system integrity |

| Exceptionally Low Friction | High-speed motor seals (18,000+ RPM) | Reduces wear & energy loss, improving efficiency & lifespan |

| Excellent Electrical Insulation | High-voltage battery & electronics insulation | Prevents short circuits, ensuring safety & reliability |

Need High-Performance PTFE Components for Your Automotive or EV Project?

KINTEK specializes in manufacturing precision PTFE seals, liners, and custom labware that meet the rigorous demands of the semiconductor, medical, and automotive industries. Our expertise in custom fabrication—from prototypes to high-volume production—ensures you get components that deliver the critical thermal stability, chemical resistance, and electrical insulation your EV systems require.

Contact KINTEK today to discuss your project requirements and discover how our PTFE solutions can enhance the reliability, safety, and efficiency of your automotive designs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers