Fundamentally, ePTFE excels in high-temperature applications because its unique, multidirectionally fibrous structure preserves the exceptional thermal stability of its base PTFE polymer. This structure ensures the gasket material resists deformation under load, maintaining a reliable, leak-free seal even when exposed to extreme heat and pressure cycling.

Choosing a gasket for high-temperature service is a critical decision where failure is not an option. The suitability of ePTFE isn't just about its high melting point; it's about its structural ability to resist deformation and maintain sealing force when conditions become intense.

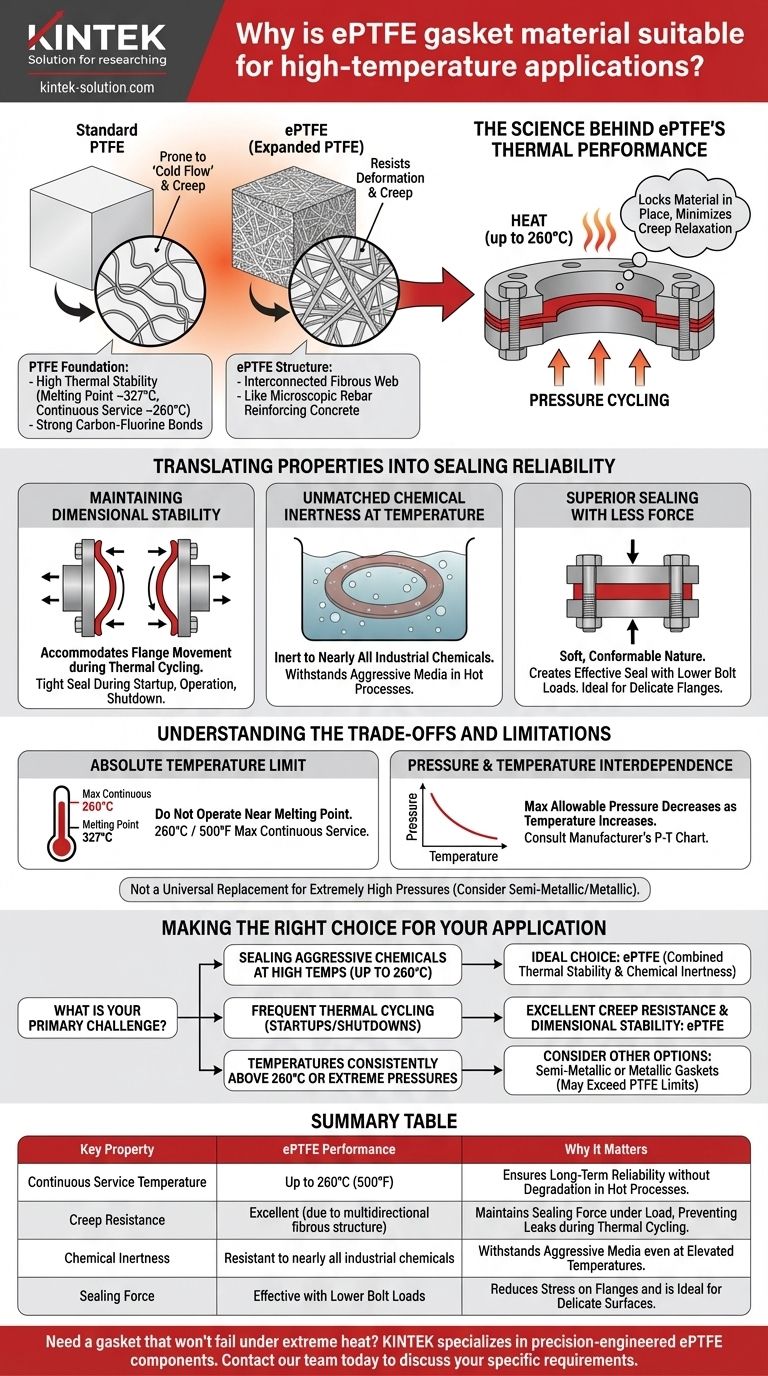

The Science Behind ePTFE's Thermal Performance

To understand why ePTFE is so effective, we must look at both its base material and its unique manufacturing process. These two factors combine to create a superior sealing product.

The Foundation: PTFE's Inherent Stability

The base polymer for ePTFE is Polytetrafluoroethylene (PTFE), which has one of the highest thermal stabilities of any plastic. Its carbon-fluorine bonds are incredibly strong, giving it remarkable properties.

PTFE has a high melting point of approximately 327°C (621°F). More importantly for real-world applications, it has a continuous service temperature of up to 260°C (500°F).

This means it can operate at these high temperatures for extended periods without degrading, breaking down, or losing its core properties.

The Critical Difference: The ePTFE Structure

Standard PTFE, while heat resistant, can be prone to "cold flow" or creep—a slow deformation under pressure. The expansion process that creates ePTFE (expanded PTFE) solves this problem.

During manufacturing, the PTFE is stretched in multiple directions. This creates an interconnected, fibrous, web-like structure.

Think of this structure as microscopic rebar reinforcing concrete. The PTFE provides the thermal and chemical resistance, while the multidirectional fibers provide the mechanical strength and dimensional stability.

Resisting Creep Relaxation

Creep relaxation is a primary cause of gasket failure in high-temperature bolted joints. It occurs when a gasket material softens and thins out under the combined effect of heat and bolt load, causing a loss of sealing stress.

The fibrous matrix of ePTFE directly counteracts this phenomenon. It locks the material in place, drastically minimizing creep and ensuring the gasket maintains its sealing force over long periods and through multiple thermal cycles.

Translating Properties into Sealing Reliability

The scientific properties of ePTFE directly translate into tangible benefits for critical industrial sealing applications.

Maintaining Dimensional Stability

Flanges expand and contract as process temperatures change. A reliable gasket must accommodate this movement without being crushed or losing its seal.

ePTFE's structural integrity allows it to maintain its dimensions and conform to the flange surfaces, even during significant thermal cycling. This ensures a tight seal during startup, operation, and shutdown.

Unmatched Chemical Inertness at Temperature

High temperatures can accelerate chemical attacks on lesser materials. PTFE is inert to nearly all industrial chemicals, a property that ePTFE fully retains.

This makes ePTFE an ideal choice for sealing aggressive media in hot processes, where other elastomers or gasket materials would quickly fail.

Superior Sealing with Less Force

The soft, conformable nature of ePTFE means it can create an effective seal with lower bolt loads compared to harder gasket materials.

This is particularly advantageous for delicate or non-metallic flange surfaces and reduces the stress placed on bolts and flanges during assembly.

Understanding the Trade-offs and Limitations

While ePTFE is a premier material, no solution is universal. Understanding its operational boundaries is key to successful application.

The Absolute Temperature Limit

It is critical to distinguish between the continuous service temperature (around 260°C / 500°F) and the melting point (327°C / 621°F). Operating near the melting point is not recommended and will lead to failure.

Pressure and Temperature Interdependence

A gasket's performance is defined by its pressure-temperature (P-T) rating. The maximum allowable operating pressure for an ePTFE gasket decreases as the temperature increases. Always consult the manufacturer's P-T chart for your specific gasket style to ensure it is suitable for your service conditions.

Not a Universal Replacement for Metal

For applications involving extremely high pressures, particularly where temperature is less of a factor, semi-metallic or solid metal gaskets may be required. ePTFE's strength lies in its performance across a combination of challenging chemical, thermal, and sealing-stress conditions.

Making the Right Choice for Your Application

Selecting the correct gasket requires matching the material's strengths to your primary operational challenge.

- If your primary focus is sealing aggressive chemicals at high temperatures (up to 260°C / 500°F): ePTFE is an ideal choice due to its combined thermal stability and near-universal chemical inertness.

- If you are dealing with frequent thermal cycling (startups/shutdowns): The excellent creep resistance and dimensional stability of ePTFE provide a more reliable, long-term seal than materials prone to flow.

- If your application involves temperatures consistently above 260°C (500°F) or extreme pressures: You should evaluate semi-metallic (e.g., spiral wound) or metallic gasket options, as you may be exceeding the operational limits of PTFE-based materials.

By understanding these principles, you can confidently specify ePTFE where its unique structural properties will deliver the most reliable and long-lasting seal.

Summary Table:

| Key Property | ePTFE Performance | Why It Matters for High-Temp Sealing |

|---|---|---|

| Continuous Service Temperature | Up to 260°C (500°F) | Ensures long-term reliability without degradation in hot processes. |

| Creep Resistance | Excellent (due to multidirectional fibrous structure) | Maintains sealing force under load, preventing leaks during thermal cycling. |

| Chemical Inertness | Resistant to nearly all industrial chemicals | Withstands aggressive media even at elevated temperatures. |

| Sealing Force | Effective with lower bolt loads | Reduces stress on flanges and is ideal for delicate surfaces. |

Need a gasket that won't fail under extreme heat? KINTEK specializes in precision-engineered ePTFE components, including custom gaskets designed for high-temperature stability and chemical resistance. Our expertise in PTFE fabrication ensures your semiconductor, medical, laboratory, or industrial application gets a reliable, leak-free seal—from prototypes to high-volume orders. Contact our team today to discuss your specific requirements and let us provide a solution that stands up to the heat.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What material grades are available for PTFE caps? Choose the Right Grade for Purity or Performance

- What are the key properties of PTFE that benefit gland packing? Achieve Superior Sealing Performance

- What are the general properties and applications of Teflon industrial coatings? Solve Complex Engineering Challenges

- What are Teflon encapsulated silicone o-rings made of? A Hybrid Seal for Extreme Conditions

- Can PTFE rotary shaft seals be customized for specific needs? Tailor for Speed, Temperature & Chemical Resistance

- How does PTFE's low friction performance benefit industrial applications? Enable Clean, Reliable Movement Without Lubricants

- Why are envelope gaskets also called 'encased' or 'enclosed' PTFE seals? The Key to Superior Chemical Sealing

- How does gland packing function in sealing systems? Achieve Reliable, Controlled Sealing