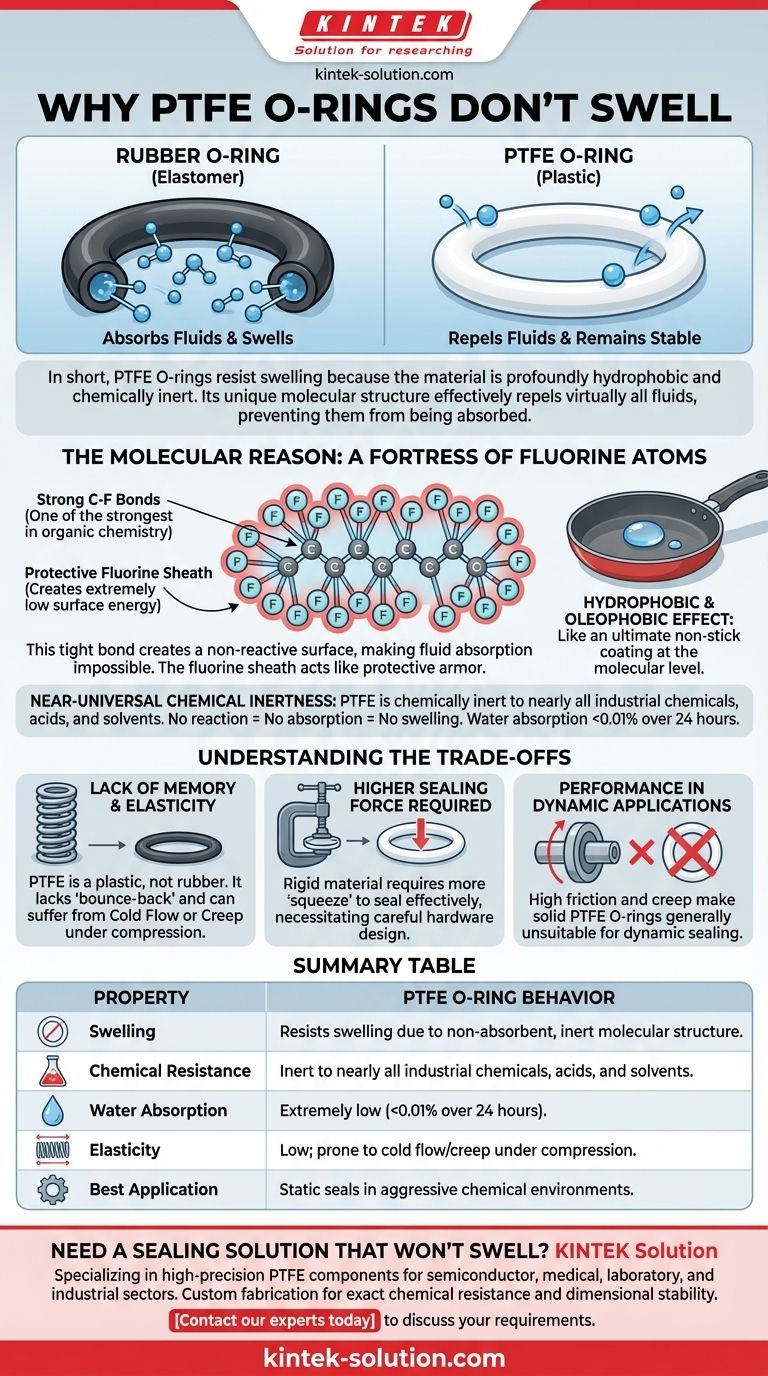

In short, PTFE O-rings resist swelling because the material is profoundly hydrophobic and chemically inert. Its unique molecular structure effectively repels virtually all fluids, preventing them from being absorbed. This non-absorbent nature ensures the O-ring maintains its original dimensions and integrity, even after prolonged exposure to aggressive chemicals or water.

The core reason for PTFE's stability lies in its molecular architecture. The incredibly strong bonds between carbon and fluorine atoms create a non-reactive, non-stick surface at the microscopic level, making fluid absorption—and therefore swelling—physically impossible.

The Molecular Reason for PTFE's Stability

To understand why PTFE (polytetrafluoroethylene) doesn't swell, we have to look at its fundamental chemistry. Unlike traditional rubber elastomers, PTFE behaves less like a sponge and more like an impenetrable barrier.

A Fortress of Fluorine Atoms

The PTFE molecule is composed of a long chain of carbon atoms completely surrounded by a sheath of fluorine atoms. The bond between carbon and fluorine (C-F) is one of the strongest single bonds in organic chemistry.

This tight, powerful bond creates an incredibly stable and non-reactive structure. The fluorine atoms act like a protective armor around the vulnerable carbon backbone.

The Hydrophobic and Oleophobic Effect

This fluorine sheath also creates an extremely low surface energy. This means liquids, whether they are water-based (hydrophobic) or oil-based (oleophobic), are not attracted to the surface and are repelled.

Think of it as the most effective non-stick coating imaginable at a molecular level. Fluids simply bead up and cannot find a way to penetrate the material's matrix.

Near-Universal Chemical Inertness

Because of its stable C-F bonds, PTFE is inert to nearly all industrial chemicals, acids, and solvents. It does not react with the surrounding media.

Swelling often occurs when a material's molecules are forced apart by the molecules of a fluid they have absorbed. Since PTFE doesn't react with or absorb the fluid, this mechanism is completely neutralized.

Extremely Low Absorption

The direct result of this chemistry is that PTFE has one of the lowest absorption rates of any solid material. For example, its water absorption over a 24-hour period is often cited as less than 0.01%.

With no fluid entering the material, there is no mechanism to cause an increase in volume. No absorption means no swelling.

Understanding the Trade-offs of PTFE

While its resistance to swelling is a significant advantage, PTFE's unique properties also introduce critical mechanical limitations that must be considered. It is not a direct replacement for a standard rubber O-ring in every situation.

Lack of "Memory" and Elasticity

PTFE is technically a plastic, not an elastomer (rubber). It lacks the "bounce-back" or elasticity of materials like Nitrile or Viton™.

If a PTFE O-ring is over-compressed, it will not return to its original shape. This phenomenon, known as cold flow or creep, can lead to a loss of sealing pressure over time.

Higher Sealing Force Required

Because it is a relatively rigid material, a PTFE O-ring requires more compressive force—or "squeeze"—to achieve an effective seal compared to a softer, more flexible elastomer.

This necessitates careful hardware design to ensure the seal is sufficiently energized without being permanently deformed.

Performance in Dynamic Applications

Due to its high coefficient of friction (when not filled with a lubricant) and its tendency to creep, solid PTFE O-rings are generally not recommended for dynamic sealing applications, such as in rotating shafts or reciprocating pistons.

Making the Right Choice for Your Goal

The decision to use PTFE depends entirely on balancing its unmatched chemical stability against its mechanical limitations.

- If your primary focus is absolute chemical inertness or zero fluid absorption: PTFE is the unparalleled choice, especially for static seals in aggressive chemical processing, pharmaceutical, or food-grade systems.

- If your primary focus is a resilient, dynamic seal that must rebound after repeated compression: A traditional elastomer like FKM (Viton™) or EPDM is a better fit, provided it is chemically compatible with your media.

- If you need a balance of both chemical resistance and elasticity: Consider an encapsulated O-ring, which features a flexible elastomeric core protected by a thin, seamless PTFE jacket.

By understanding the molecular behavior of PTFE, you can leverage its exceptional stability while respecting its mechanical constraints.

Summary Table:

| Property | PTFE O-Ring Behavior |

|---|---|

| Swelling | Resists swelling due to non-absorbent, inert molecular structure |

| Chemical Resistance | Inert to nearly all industrial chemicals, acids, and solvents |

| Water Absorption | Extremely low (<0.01% over 24 hours) |

| Elasticity | Low; prone to cold flow/creep under compression |

| Best Application | Static seals in aggressive chemical environments |

Need a sealing solution that won't swell, even in the most aggressive chemical environments?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a component with the exact chemical resistance and dimensional stability your application demands.

Contact our experts today to discuss your specific requirements and leverage our precision production capabilities for your next project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments