Simply put, Polytetrafluoroethylene (PTFE) cannot be processed using conventional techniques because its viscosity is extraordinarily high. Even when heated well above its melting point, PTFE does not flow like a typical liquid plastic. Instead of melting into a fluid state suitable for injection molding or extrusion, it transitions into a gel-like solid that resists being pushed through a mold.

The core issue is that PTFE's immense melt viscosity prevents it from ever becoming a true, flowable liquid. This forces the adoption of a completely different manufacturing process, similar to powder metallurgy, where the material is compressed first and then heated to fuse the particles together.

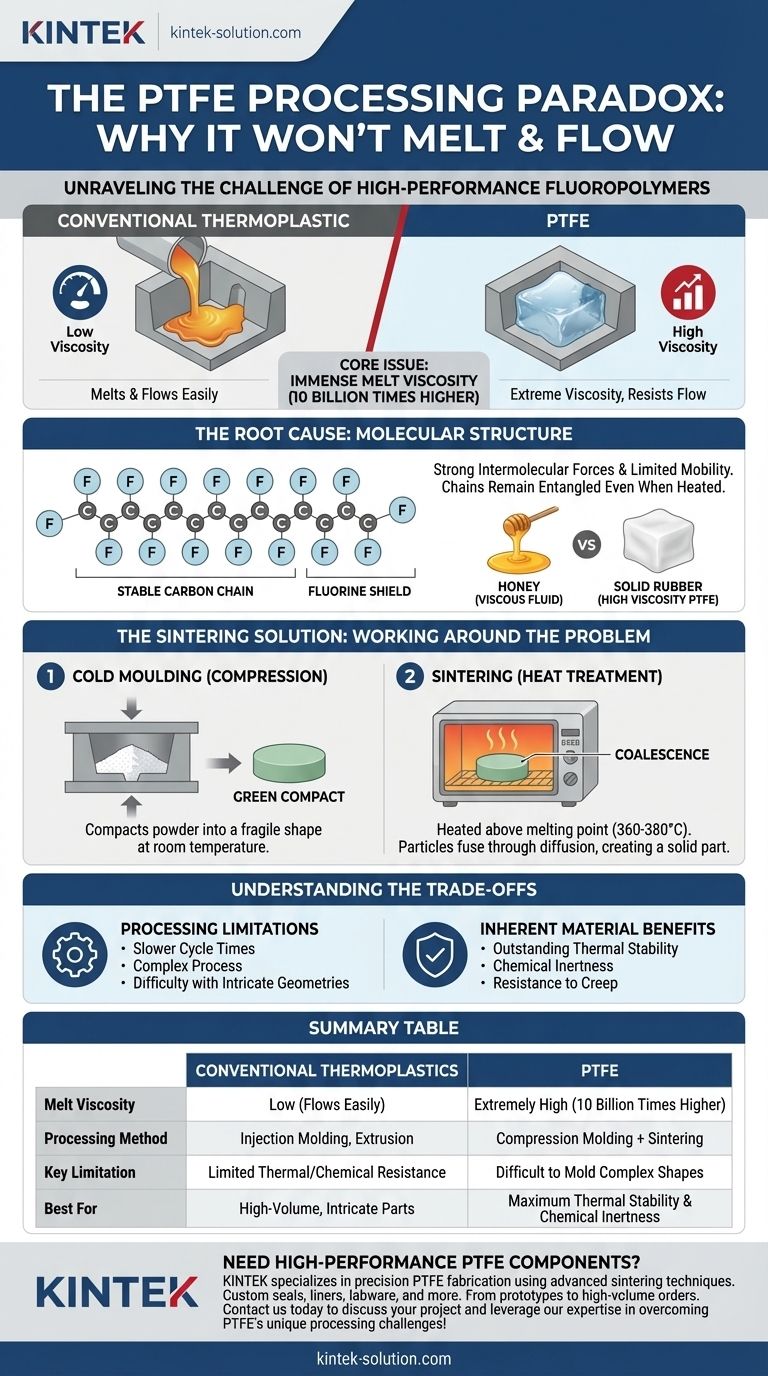

The Root Cause: Extreme Melt Viscosity

To understand the processing challenge, we must first understand what "high viscosity" truly means in the context of PTFE. It's a difference of kind, not just degree.

What High Viscosity Means for PTFE

Viscosity is a measure of a fluid's resistance to flow. For most thermoplastics, heating them past their melting point dramatically lowers their viscosity, allowing them to be easily injected into a mold.

PTFE behaves differently. Its melt viscosity is around 10 billion times higher than that of common plastics like polypropylene.

This isn't like comparing honey to water; it's like comparing a solid block of rubber to water. The material will deform under immense pressure, but it will not flow to fill the intricate details of a mold.

The Origin of the Problem

This unique behavior stems from PTFE's molecular structure. It consists of a long, stable carbon chain completely shielded by larger fluorine atoms.

This structure creates incredibly strong intermolecular forces and limits the mobility of the polymer chains. Even when enough thermal energy is applied to break the crystalline structure (melting), the chains remain entangled and unable to slide past one another freely.

The Sintering Solution: Working Around the Problem

Since you cannot melt and mold PTFE in the traditional sense, engineers developed a multi-step process that works around its high viscosity. This method involves compressing the material when cold and then fusing it with heat.

Step 1: Cold Moulding (or Compression)

The process begins with PTFE in a powder or granular form. This powder is poured into a mold and subjected to high pressure at room temperature.

This step, often called preforming, compacts the powder into the desired shape. The individual particles are simply held together by mechanical force, resulting in a fragile part often called a "green" compact.

Step 2: Sintering (Heat Treatment)

The preformed part is then carefully removed from the mold and heated in an oven to a temperature above PTFE's melting point (around 360-380°C).

During sintering, the material does not melt and flow. Instead, the molecules at the surface of each individual particle become mobile enough to diffuse across the particle boundaries, entangling with the molecules of neighboring particles. This process, called coalescence, fuses the particles into a solid, dense, and durable final product.

Understanding the Trade-offs

This specialized process is both a limitation and a key to PTFE's remarkable properties. The very characteristic that makes it difficult to process is also what gives it its value.

Processing Limitations

Compared to injection molding, sintering is a slower and more complex process. Cycle times are significantly longer, which increases manufacturing costs.

It is also more difficult to create parts with extremely sharp corners, thin walls, or highly intricate geometries. Finally, if the process is not controlled perfectly, it can result in residual porosity within the final part.

Inherent Material Benefits

The extreme viscosity and strong molecular structure are directly responsible for PTFE's most prized characteristics. Its outstanding thermal stability, chemical inertness, and resistance to creep (deformation under load) are all byproducts of the properties that prevent melt processing.

In essence, you are trading ease of manufacturing for superior material performance in harsh environments.

Making the Right Choice for Your Goal

Understanding this fundamental processing difference is critical when selecting a material for a high-performance application.

- If your primary focus is mass production of complex parts: Standard PTFE may be unsuitable. Instead, investigate melt-processable fluoropolymers like FEP or PFA, which offer similar properties with the ability to be injection molded, at the cost of slightly lower thermal performance.

- If your primary focus is maximum thermal stability and chemical resistance: The unique properties of sintered PTFE are often non-negotiable. The manufacturing method is a necessary trade-off to achieve the highest level of performance.

Ultimately, PTFE's processing method is a direct consequence of the molecular structure that makes it one of the most capable polymers available.

Summary Table:

| Aspect | Conventional Thermoplastics | PTFE |

|---|---|---|

| Melt Viscosity | Low (flows easily) | Extremely high (10 billion times higher) |

| Processing Method | Injection molding, extrusion | Compression molding + sintering |

| Key Limitation | Limited thermal/chemical resistance | Difficult to mold complex shapes |

| Best For | High-volume, intricate parts | Maximum thermal stability & chemical inertness |

Need high-performance PTFE components? KINTEK specializes in precision PTFE fabrication using advanced sintering techniques. We manufacture custom seals, liners, and labware for semiconductor, medical, and industrial applications—from prototypes to high-volume orders. Contact us today to discuss your project and leverage our expertise in overcoming PTFE's unique processing challenges!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Evaporating Dishes for Diverse Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications