In the demanding environment of medical technology, spring-energized PTFE seals are preferred for their unparalleled combination of material purity, extreme chemical resistance, and consistent mechanical performance. This design ensures sterile, leak-free operation in critical applications like surgical tools, pumps, and diagnostic equipment, where standard elastomeric seals would degrade or fail under aggressive sterilization and operational stresses.

While conventional seals are sufficient for many uses, spring-energized PTFE seals are the definitive solution for conditions involving aggressive chemicals, extreme temperatures, or high pressures. Their core design principle guarantees a reliable seal when performance and purity are non-negotiable.

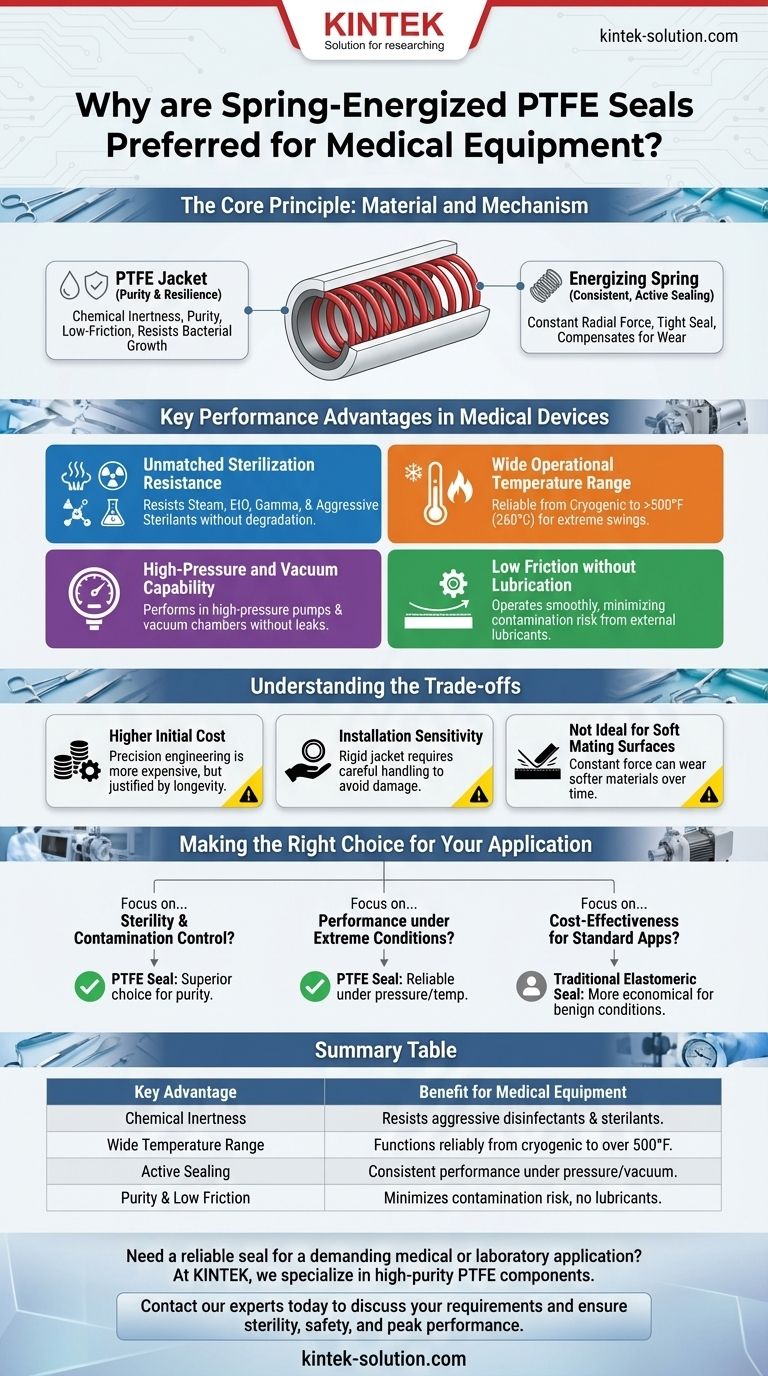

The Core Principle: Material and Mechanism

To understand their value, you must first understand how their two key components work together. The seal's performance is a direct result of combining an advanced polymer jacket with a resilient metal spring.

The PTFE Jacket: Purity and Resilience

Polytetrafluoroethylene (PTFE) is a fluoropolymer known for its remarkable properties. The jacket, made from a PTFE-based compound, provides the primary interface with the operating environment.

Its key advantages are chemical inertness and purity. PTFE is virtually immune to degradation from the aggressive disinfectants, cleaning agents, and sterilization processes (like steam autoclaving) common in medical settings.

Furthermore, its surface is inherently low-friction and resists bacterial growth, minimizing the risk of contamination in fluid paths.

The Energizing Spring: Consistent, Active Sealing

Unlike a standard elastomeric O-ring which seals passively through compression, a spring-energized seal is an active system. A metal spring inside the PTFE jacket exerts a constant, uniform radial force.

This force presses the lips of the seal firmly against the mating surfaces. This design ensures a tight seal even with fluctuations in temperature, pressure, or minor hardware misalignments. It also compensates for material wear over the seal's lifetime, ensuring long-term reliability.

Key Performance Advantages in Medical Devices

The combination of the PTFE jacket and energizer spring delivers specific, critical advantages for medical and laboratory equipment.

Unmatched Sterilization Resistance

Medical components must withstand repeated, harsh sterilization cycles. Spring-energized PTFE seals do not swell, crack, or degrade when exposed to steam, ethylene oxide (EtO), gamma radiation, or aggressive chemical sterilants, ensuring device integrity.

Wide Operational Temperature Range

These seals function reliably in both cryogenic applications, such as in equipment for tissue preservation, and at high temperatures exceeding 500°F (260°C). This makes them ideal for devices that experience wide temperature swings during operation or sterilization.

High-Pressure and Vacuum Capability

The constant force from the spring allows these seals to perform exceptionally well in high-pressure pumps and fluid handling systems. It also ensures a tight seal in vacuum chambers, preventing leaks that could compromise a sterile environment or a diagnostic process.

Low Friction without Lubrication

The low coefficient of friction of PTFE means the seal operates smoothly without external lubricants. This is critical in medical applications where lubricants could become a source of contamination or react with sensitive media.

Understanding the Trade-offs

While highly effective, these seals are not a universal solution. Acknowledging their limitations is key to proper specification.

Higher Initial Cost

A multi-component, precision-engineered seal is inherently more expensive than a simple molded elastomeric O-ring. The cost is justified by performance and longevity in applications where a standard seal would fail.

Installation Sensitivity

The PTFE jacket is a relatively rigid polymer. Care must be taken during installation to avoid scratching or gouging the sealing lips, which could compromise performance. They are less forgiving of improper handling than a flexible rubber seal.

Not Ideal for Soft Mating Surfaces

The constant, concentrated force from the spring can, over millions of cycles, cause wear on softer mating surfaces like some plastics or soft metals. The hardware's material compatibility must be considered during the design phase.

Making the Right Choice for Your Application

Your choice of seal should be dictated by the specific demands of the application.

- If your primary focus is sterility and contamination control: The chemical inertness and purity of PTFE make these seals the superior choice, as they will not degrade or leach materials when exposed to aggressive cleaning agents.

- If your primary focus is performance under extreme conditions: For devices operating at high pressures, vacuums, or across wide temperature ranges, the spring-energizer ensures a constant, reliable seal where elastomers would fail.

- If your primary focus is cost-effectiveness for a standard application: In low-pressure, ambient-temperature environments with benign media, a traditional elastomeric seal is often a more practical and economical solution.

Ultimately, selecting a spring-energized PTFE seal is an investment in reliability and safety for the most demanding medical applications.

Summary Table:

| Key Advantage | Benefit for Medical Equipment |

|---|---|

| Chemical Inertness | Resists aggressive disinfectants & sterilants without degradation. |

| Wide Temperature Range | Functions reliably from cryogenic to over 500°F (260°C). |

| Active Sealing | Spring ensures consistent performance under pressure, vacuum, and temperature fluctuations. |

| Purity & Low Friction | Inert surface minimizes contamination risk and operates without lubricants. |

Need a reliable seal for a demanding medical or laboratory application?

At KINTEK, we specialize in manufacturing high-purity PTFE components, including custom spring-energized seals. Our precision production ensures the performance and reliability your critical equipment demands, from prototypes to high-volume orders.

Contact our experts today to discuss your specific requirements and ensure sterility, safety, and peak performance in your designs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability