In high surface speed applications, PTFE seals are the preferred choice because their unique molecular structure provides an extremely low coefficient of friction, which generates significantly less heat than traditional seals. This inherent lubricity, combined with an exceptional resistance to high temperatures, allows PTFE to maintain its integrity and sealing performance under conditions that would cause elastomeric seals to rapidly degrade and fail.

The core problem with high speed is not the motion itself, but the destructive frictional heat it creates. PTFE seals dominate in these environments because they uniquely solve both sides of the heat equation: they generate far less of it and are highly resistant to the heat that is produced.

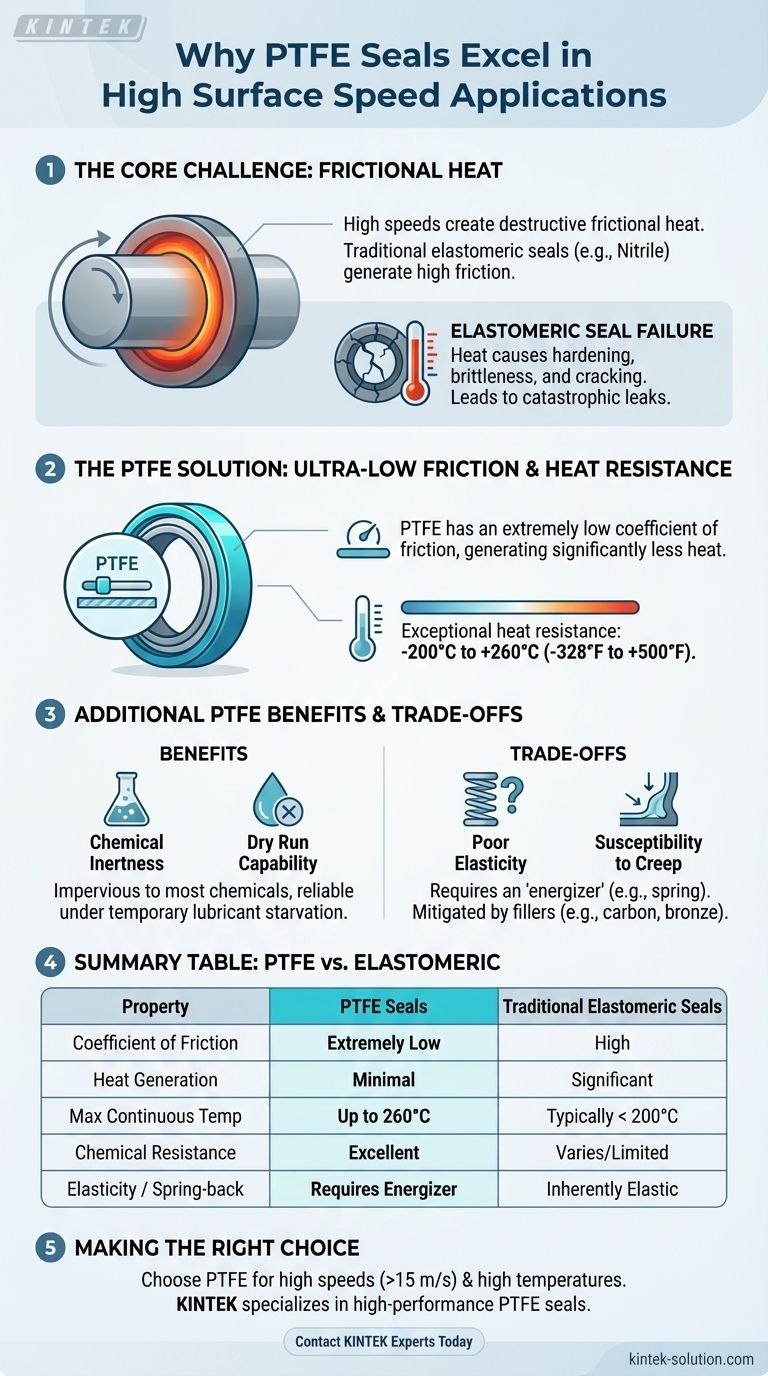

The Core Challenge: Frictional Heat at High Speeds

At the interface between a rotating shaft and a stationary seal, speed is the primary driver of a critical failure mechanism: heat. Understanding this relationship is key to appreciating why material choice is so important.

How High Speeds Create Destructive Heat

Every dynamic seal generates some heat due to friction. As surface speed increases, the energy converted into heat at the contact point rises dramatically.

This localized temperature spike can easily exceed the operational limits of many materials, initiating a cascade of failure events.

The Failure of Standard Elastomeric Seals

Traditional elastomeric seals, like those made from Nitrile or Viton, have a relatively high coefficient of friction. At high speeds, the intense heat they generate causes the material to harden, become brittle, and crack.

This degradation eliminates the seal's flexibility, which is essential for maintaining contact with the shaft, leading to catastrophic leaks. The heat can also break down the lubricant, further accelerating wear and failure.

Why PTFE Excels Where Others Fail

Polytetrafluoroethylene (PTFE) possesses a combination of properties that directly counteracts the destructive forces present in high-velocity applications.

The Primary Advantage: Ultra-Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This "slipperiness" is its most critical advantage in high-speed scenarios.

By minimizing friction at the source, a PTFE seal generates substantially less heat than an elastomeric equivalent under the same operating conditions. This prevents the system from ever reaching a critical temperature threshold.

The Critical Safety Net: Exceptional Heat Resistance

While PTFE generates less heat, it is also exceptionally capable of withstanding it. The material remains stable across a vast temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This high thermal stability ensures that even the heat generated during demanding, high-speed rotations will not cause the seal to degrade, melt, or lose its sealing properties.

Additional High-Performance Properties

Beyond friction and heat, PTFE's chemical structure provides further benefits. It is chemically inert and impervious to almost all industrial fluids and chemicals.

This quality, along with its ability to run dry for short periods, makes it an incredibly robust and reliable choice for critical systems where contamination or lubricant starvation are potential concerns.

Understanding the Practical Trade-offs

While superior in high-speed dynamics, PTFE is not a universal solution. Its physical properties introduce specific design considerations.

The Challenge of Elasticity

PTFE is a plastic, not a rubber-like elastomer. It has poor "elastic memory," meaning it does not readily return to its original shape after being deformed.

Because of this, PTFE seals often incorporate an energizer, such as a stainless steel spring or an O-ring, to provide a constant radial force and ensure consistent contact with the shaft.

Susceptibility to Creep

Under a constant load, PTFE can be prone to "cold flow" or creep, where the material slowly deforms over time. Seal manufacturers mitigate this by adding fillers like carbon, glass fiber, or bronze to the PTFE compound.

These fillers enhance the material's mechanical strength and resistance to creep, but they must be chosen carefully to match the application's demands.

Making the Right Choice for Your Application

Selecting the correct seal material requires a clear understanding of your system's primary operational stressor.

- If your primary focus is high surface speeds (e.g., above 15 m/s) and high temperatures: PTFE is the definitive choice for its unmatched low-friction and high-temperature performance.

- If your primary focus is low-speed or static sealing in a stable temperature range: A standard elastomeric seal often provides a more cost-effective and simpler installation solution.

- If your primary focus is aggressive chemical compatibility at any speed: PTFE's chemical inertness gives it a significant reliability advantage over nearly all elastomers.

Ultimately, choosing PTFE for high-velocity systems is a strategic decision to engineer against the fundamental risk of heat-induced failure.

Summary Table:

| Property | PTFE Seals | Traditional Elastomeric Seals |

|---|---|---|

| Coefficient of Friction | Extremely Low | High |

| Heat Generation | Minimal | Significant |

| Max Continuous Temp | Up to 260°C (500°F) | Typically < 200°C (392°F) |

| Chemical Resistance | Excellent (Chemically Inert) | Varies, Often Limited |

| Elasticity / Spring-back | Requires an Energizer (e.g., spring) | Inherently Elastic |

Need reliable seals for your high-speed application? KINTEK specializes in manufacturing high-performance PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get a solution engineered for peak performance and durability. Contact our experts today to discuss how our PTFE seals can solve your high-speed sealing challenges!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems