PTFE rotary shaft seals are essential for high-performance applications because their unique material properties allow them to operate reliably under extreme conditions where traditional elastomeric seals would quickly fail. They excel at handling high speeds, aggressive chemicals, and wide temperature ranges, ensuring equipment longevity and reducing maintenance.

While conventional seals often fail due to friction-induced heat, chemical degradation, or temperature extremes, PTFE seals are engineered to thrive in these environments. Their core advantage lies in an exceptionally low coefficient of friction, which fundamentally changes the performance equation for demanding machinery.

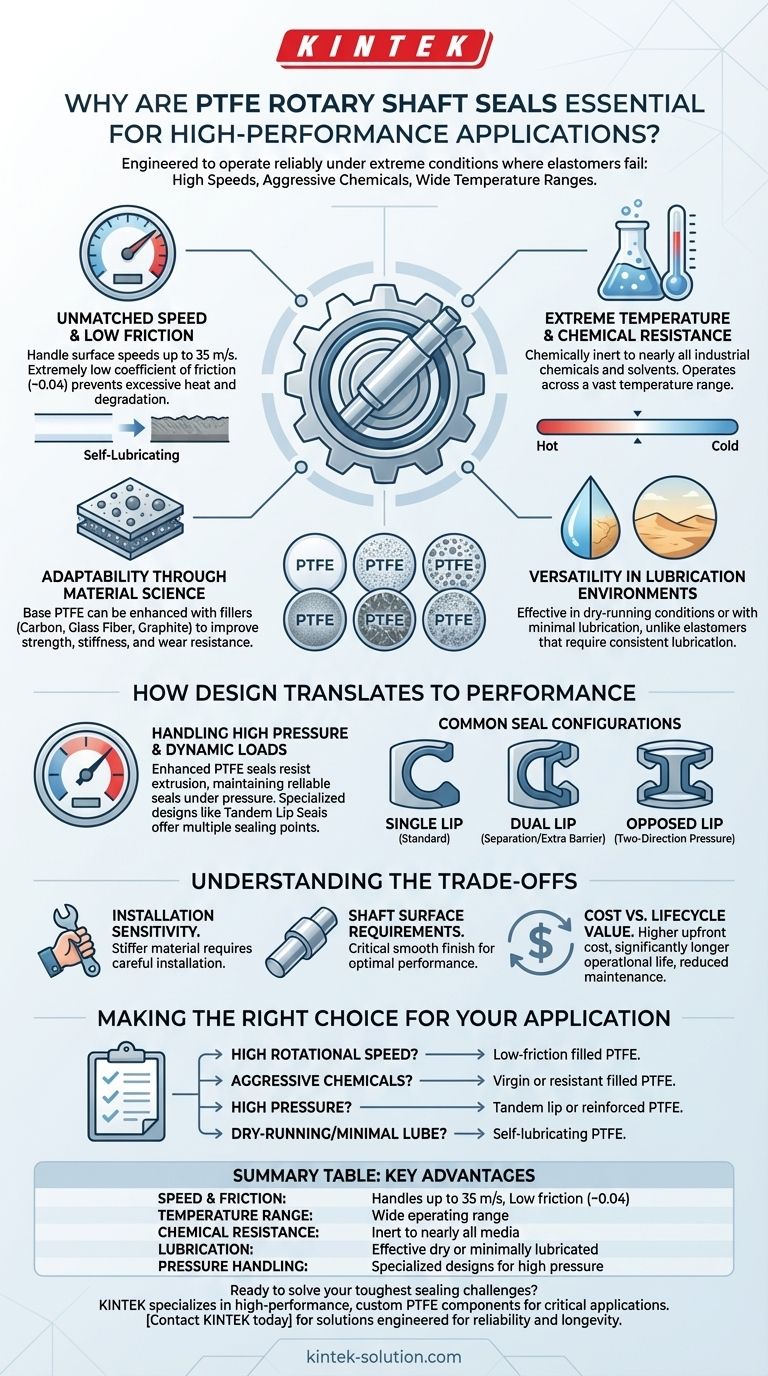

The Core Advantages of PTFE in Sealing

To understand why PTFE seals are specified for critical applications, from aerospace engines to industrial compressors, we must look at their fundamental material properties. These characteristics work in concert to deliver a level of performance that other materials cannot match.

Unmatched Speed and Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, as low as 0.04 for virgin PTFE. This self-lubricating property is critical.

It allows PTFE seals to handle shaft surface speeds up to 35 m/s without generating excessive heat. This thermal stability prevents the material degradation and premature failure that plagues other seals in high-speed rotations.

Extreme Temperature and Chemical Resistance

PTFE is chemically inert and resistant to nearly all industrial chemicals and solvents. This makes it the default choice for sealing applications in the chemical processing, pharmaceutical, and food and beverage industries.

Furthermore, it maintains its integrity across a vast temperature range, operating effectively in conditions far too hot or cold for standard elastomers.

Adaptability Through Material Science

Base PTFE is not a single solution but a platform. It can be enhanced with various fillers—such as carbon, glass fiber, or graphite—to improve specific properties.

These fillers can dramatically increase compressive strength, stiffness, and wear resistance, allowing engineers to create custom seal compounds tailored to the precise demands of an application.

How PTFE Seal Design Translates to Performance

The raw material properties of PTFE are only part of the story. The way these materials are engineered into specific seal designs is what unlocks their full potential in real-world machinery.

Versatility in Lubrication Environments

The self-lubricating nature of PTFE means these seals can operate effectively in dry-running conditions or with minimal lubrication.

This versatility is a significant advantage over elastomeric seals, which typically require a consistent lubricant film to function without rapid wear and failure.

Handling High Pressure and Dynamic Loads

When enhanced with the right fillers, PTFE seals exhibit excellent strength and resistance to extrusion. This allows them to maintain a reliable seal under high-pressure conditions.

Specialized designs, like Tandem Lip Seals, are specifically engineered for high-pressure applications, providing multiple sealing points for maximum reliability.

Common Seal Configurations

Different designs are optimized for specific challenges:

- Single Lip Seals: Best for standard lubricated, low-pressure environments.

- Dual Lip Seals: Ideal for separating two different fluids or for providing an extra barrier against contaminants in both lubricated and non-lubricated systems.

- Opposed Lip Seals: Used to handle pressure from two directions, often found in harsh or contaminated environments.

Understanding the Trade-offs

While highly effective, PTFE seals are a specialized component, and specifying them requires acknowledging a few key considerations to ensure success. Their unique properties introduce trade-offs compared to more flexible elastomeric seals.

Installation Sensitivity

PTFE is a much stiffer material than rubber. This means PTFE seals are less forgiving of installation errors and often require specialized tools or procedures to prevent damage to the sealing lip during assembly.

Shaft Surface Requirements

To leverage PTFE's low-friction properties effectively, the mating shaft surface finish is critical. A smoother, properly prepared shaft surface is necessary to ensure a long and reliable service life.

Cost vs. Lifecycle Value

PTFE seals typically have a higher upfront cost than their elastomeric counterparts. However, this initial investment is often justified by a significantly longer operational life, reduced downtime, and lower maintenance requirements, resulting in a lower total cost of ownership.

Making the Right Choice for Your Application

Selecting the correct seal is about aligning the material and design with the primary challenge of your system.

- If your primary focus is high rotational speed: A PTFE seal with a low-friction filler is your best choice to minimize heat generation and prevent premature failure.

- If your primary focus is aggressive chemical exposure: A virgin PTFE or a chemically-resistant filled PTFE seal will provide the necessary inertness where elastomers would degrade.

- If your primary focus is high pressure: A tandem lip seal design or a PTFE compound reinforced for compressive strength is essential to prevent extrusion.

- If your primary focus is dry-running or minimal lubrication: The self-lubricating nature of PTFE makes it the only viable option for long-term reliability.

By understanding these core principles, you can confidently specify PTFE seals to achieve superior reliability and performance in your most critical applications.

Summary Table:

| Key Advantage | PTFE Seal Performance |

|---|---|

| Speed & Friction | Handles up to 35 m/s surface speed with a low coefficient of friction (~0.04) |

| Temperature Range | Operates effectively across a vast temperature range, far exceeding standard elastomers |

| Chemical Resistance | Inert to nearly all industrial chemicals, solvents, and aggressive media |

| Lubrication | Can operate reliably in dry-running or minimally lubricated conditions |

| Pressure Handling | Specialized designs (e.g., Tandem Lip) maintain seals under high-pressure and dynamic loads |

Ready to solve your toughest sealing challenges? KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production and custom fabrication, from prototypes to high-volume orders, ensures you get a sealing solution engineered for reliability and longevity in your specific application. Contact KINTEK today to discuss your requirements and discover the value of a partnership focused on your success.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability