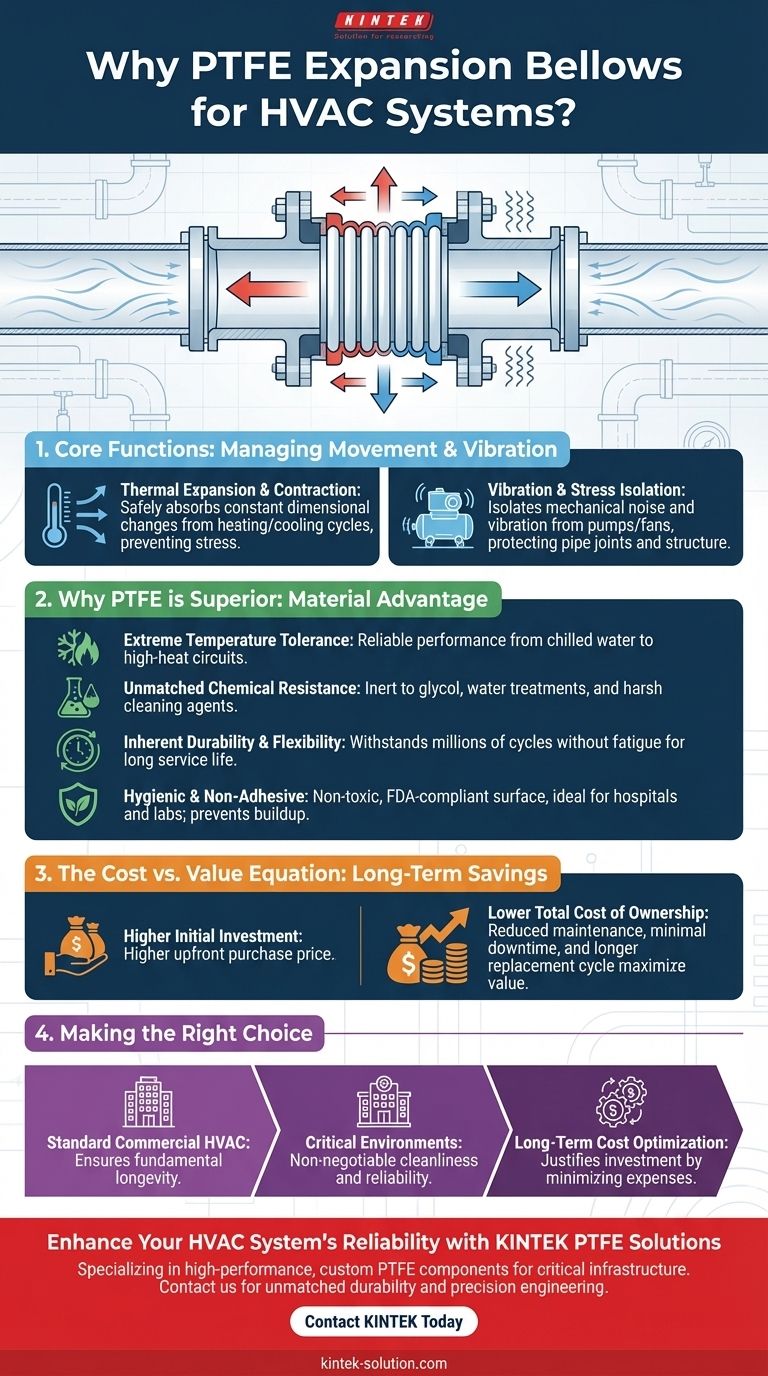

At their core, PTFE expansion bellows are exceptionally well-suited for HVAC systems because they safely absorb the constant thermal expansion and contraction of pipework. Their unique material properties also provide outstanding resistance to system vibration, extreme temperatures, and chemical exposure, ensuring long-term operational integrity and reliability.

The decision to use PTFE bellows in an HVAC system is not merely about managing movement. It is a strategic choice for ensuring long-term system health, minimizing maintenance, and guaranteeing performance, especially in critical or demanding environments.

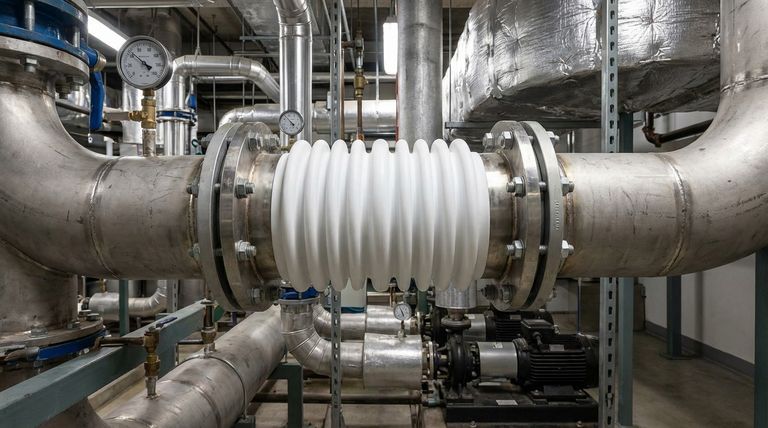

The Core Functions in an HVAC Context

PTFE expansion bellows perform two primary, non-negotiable jobs within an HVAC system: managing movement and isolating vibration. These functions are critical for preventing premature failure of pipes, ducts, and connected equipment.

Managing Thermal Expansion and Contraction

HVAC systems constantly cycle between heating and cooling, causing metal and plastic pipes to expand and contract. Without a flexible component to absorb this movement, the stress would transfer to fixed points, leading to leaks, cracks, and catastrophic system failure.

PTFE expansion bellows act as the flexible joint in the system, compressing and extending to accommodate these dimensional changes safely.

Absorbing System Vibration and Stress

Pumps, compressors, and fans are the heart of any HVAC system, but they also introduce constant vibration and noise. These vibrations create mechanical stress that can weaken pipe joints and supports over time.

PTFE bellows isolate this vibration, preventing it from propagating through the pipework. This not only protects the structural integrity of the system but also significantly reduces operational noise.

Why PTFE is a Superior Material for HVAC

While other materials can provide flexibility, Polytetrafluoroethylene (PTFE) offers a unique combination of properties that make it an ideal choice for the demanding conditions inside modern HVAC infrastructure.

Extreme Temperature Tolerance

HVAC systems operate across a wide temperature spectrum, from chilled water lines to high-temperature heating circuits. PTFE excels in these conditions, maintaining its structural integrity and flexibility without becoming brittle in the cold or degrading in the heat.

Unmatched Chemical Resistance

PTFE is virtually inert, making it resistant to the chemicals commonly found in HVAC systems, including water treatment additives, glycol-based coolants, and harsh cleaning agents. This chemical stability prevents corrosion and material degradation, extending the life of the component.

Inherent Durability and Flexibility

The molecular structure of PTFE allows it to withstand millions of cycles of compression and extension without fatigue. This ensures a long service life and makes it a reliable, “fit-and-forget” component that enhances overall system reliability.

Hygienic and Non-Adhesive Surface

PTFE is a non-toxic, FDA-compliant material with a non-stick surface. In sensitive applications like hospitals, laboratories, or food processing facilities, this prevents the buildup of contaminants and simplifies system cleaning, contributing to better air quality and hygiene.

Understanding the Trade-offs: The Cost vs. Value Equation

A complete analysis requires an objective look at the primary drawback of PTFE components: the initial cost. However, this must be weighed against their long-term value.

The Higher Initial Investment

PTFE expansion bellows typically have a higher upfront purchase price compared to options made from rubber or metal. This initial cost can be a point of hesitation during budget planning.

Long-Term Operational Savings

The true value of PTFE is realized over the system's lifespan. Their exceptional durability and resistance to chemical and thermal degradation result in a significantly lower total cost of ownership.

This is achieved through dramatically reduced maintenance needs, minimal risk of costly downtime for repairs, and a much longer replacement cycle compared to less robust materials.

Making the Right Choice for Your System

Selecting PTFE expansion bellows is an investment in operational resilience. The decision should be guided by the specific demands of your HVAC application.

- If your primary focus is standard commercial HVAC: PTFE bellows are a reliable choice for preventing pipe stress and absorbing equipment vibration, ensuring the fundamental longevity of the system.

- If your primary focus is a critical environment (hospitals, labs): The hygienic, non-toxic, and chemical-resistant properties of PTFE are non-negotiable for ensuring system cleanliness and reliability.

- If your primary focus is long-term cost optimization: The superior durability and low maintenance needs of PTFE justify the initial investment by minimizing expensive downtime and frequent replacement costs.

Ultimately, choosing PTFE expansion bellows is an investment in the predictable and uninterrupted performance of your entire HVAC system.

Summary Table:

| Key Property | Benefit for HVAC Systems |

|---|---|

| Thermal Flexibility | Safely absorbs pipe expansion/contraction from heating/cooling cycles. |

| Vibration Dampening | Isolates stress from pumps and compressors, protecting equipment. |

| Extreme Temperature Tolerance | Performs reliably from chilled water to high-heat circuits. |

| Superior Chemical Resistance | Withstands glycol, water treatments, and cleaning agents without corroding. |

| Hygienic, Non-Toxic Surface | Ideal for hospitals, labs, and food processing; prevents contaminant buildup. |

| Long Service Life | High cycle life reduces maintenance, downtime, and replacement costs. |

Enhance Your HVAC System's Reliability with KINTEK PTFE Solutions

Is your HVAC system operating in a demanding environment where reliability, cleanliness, and long-term cost savings are critical? Standard components may not be enough to handle the constant thermal movement, vibration, and chemical exposure.

KINTEK specializes in manufacturing high-performance PTFE components, including custom expansion bellows, for the semiconductor, medical, laboratory, and industrial sectors. We understand the precise demands of critical infrastructure.

By choosing KINTEK, you invest in:

- Unmatched Durability: Our PTFE bellows withstand millions of cycles, ensuring a "fit-and-forget" solution.

- Precision Engineering: We prioritize exact specifications for perfect integration and performance.

- Custom Fabrication: From prototypes to high-volume orders, we tailor solutions to your specific HVAC requirements.

- Reduced Total Cost of Ownership: Minimize expensive downtime and frequent replacements with components built to last.

Ready to build a more resilient and efficient HVAC system? Let our experts help you select or design the perfect PTFE expansion joint for your application.

Contact KINTEK today for a consultation and ensure the long-term health of your critical infrastructure.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- How is PTFE used in industrial processes? Maximize Safety and Efficiency