In short, PTFE bushes are preferred in harsh chemical environments because of their exceptional chemical inertness. Unlike metals that corrode or other plastics that degrade, Polytetrafluoroethylene (PTFE) remains structurally and functionally intact when exposed to a vast range of aggressive substances, from strong acids to powerful solvents. This unique resilience ensures operational reliability where other materials would quickly fail.

The core reason for choosing PTFE in harsh environments extends beyond simple survival. It's about maintaining consistent, maintenance-free performance—specifically low friction and self-lubrication—in conditions where traditional lubrication is impossible and material degradation is a constant threat.

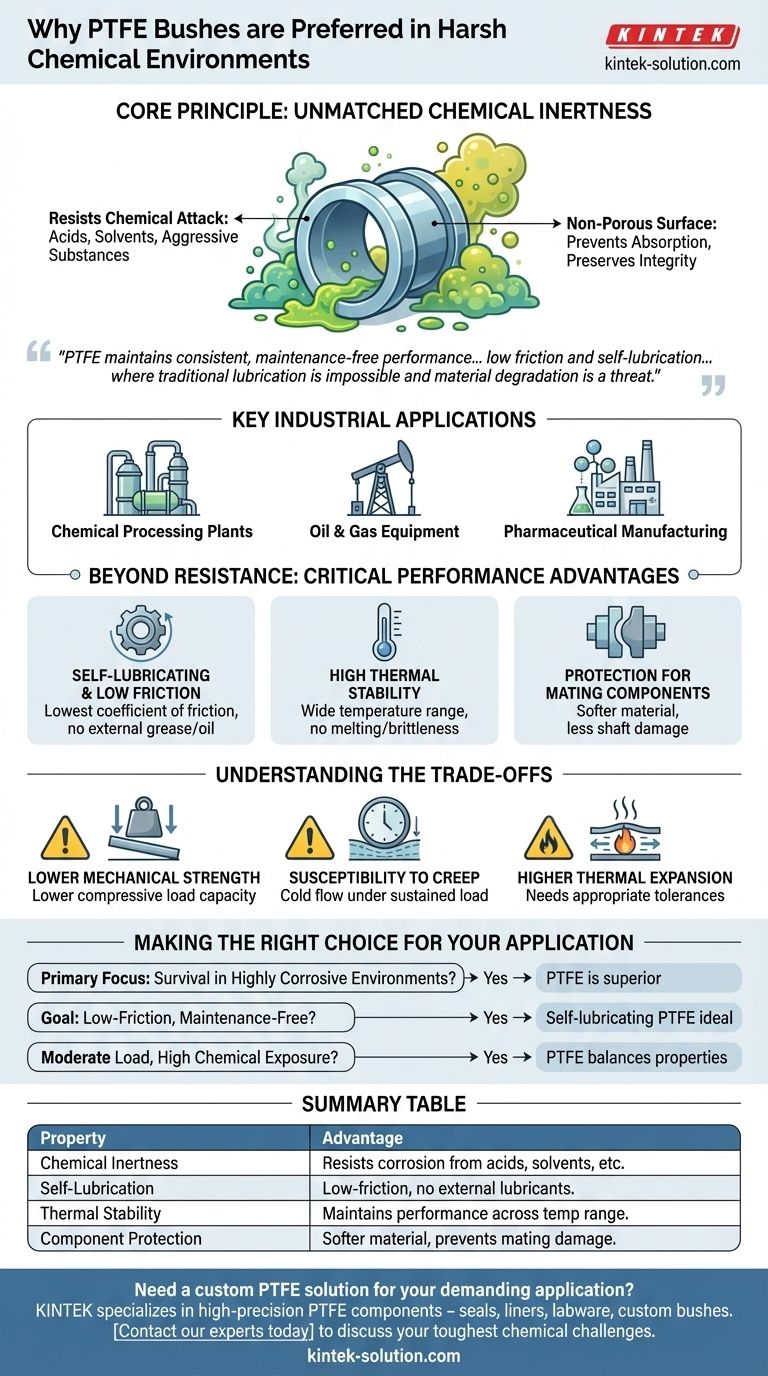

The Core Principle: Unmatched Chemical Inertness

The primary advantage of PTFE lies in its molecular structure. It is a fluoropolymer, and the bond between its carbon and fluorine atoms is one of the strongest in organic chemistry. This makes the material exceptionally stable and non-reactive.

Resisting Chemical Attack

Where metal bushings would corrode, rust, or dissolve when exposed to aggressive chemicals, PTFE remains unaffected. Its non-porous surface prevents absorption of these chemicals, preserving the bushing's integrity and dimensions.

Maintaining Performance Under Duress

This resistance isn't just about preventing destruction. It ensures that the critical properties of the bushing—like its low-friction surface—are not compromised by chemical exposure. The part continues to function as designed, preventing system failure.

Key Industrial Applications

This property makes PTFE the default choice in demanding sectors. It is heavily utilized in chemical processing plants, oil and gas equipment, and pharmaceutical manufacturing, where components are consistently exposed to corrosive materials.

Beyond Resistance: Critical Performance Advantages

While chemical inertness is the headline feature, several other properties make PTFE a superior choice for these demanding applications.

Self-Lubricating and Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This means it operates smoothly without the need for external lubricants like grease or oil, which could be washed away or contaminated by the harsh chemical environment.

High Thermal Stability

Chemical processes often involve high temperatures. PTFE maintains its key properties across a wide temperature range, ensuring it does not melt or become brittle under conditions that would compromise lesser plastics.

Protection for Mating Components

Because PTFE is a relatively soft material, it is less likely to damage or score the shafts it runs on, even softer ones. In a system where maintenance is difficult due to hazardous materials, preserving the integrity of all components is crucial.

Understanding the Trade-offs

No material is perfect for every scenario. To make an informed decision, you must be aware of PTFE's limitations.

Lower Mechanical Strength

Compared to bronze or steel, PTFE has lower compressive strength and load-bearing capacity. It is not suitable for extremely high-load or high-impact applications where mechanical force, rather than chemical exposure, is the primary challenge.

Susceptibility to Creep

Under a constant, sustained load, PTFE can slowly deform over time, a phenomenon known as "cold flow" or creep. This must be accounted for during the design phase for applications involving static, long-term pressure.

Higher Thermal Expansion

PTFE expands and contracts with temperature changes more significantly than metals. Engineers must design systems with appropriate tolerances to accommodate this thermal expansion and prevent parts from binding or becoming too loose.

Making the Right Choice for Your Application

Selecting the correct bushing material requires balancing environmental challenges with mechanical demands.

- If your primary focus is survival in highly corrosive environments: PTFE is almost always the superior choice due to its chemical inertness.

- If your goal is low-friction, maintenance-free operation in a contaminated area: The self-lubricating nature of PTFE makes it ideal where traditional lubrication would fail.

- If you are dealing with a moderate load but high chemical exposure: PTFE provides an excellent balance of properties that protects the entire assembly from both friction and corrosion.

Ultimately, choosing PTFE is a decision to prioritize reliability and performance in environments where other materials simply cannot endure.

Summary Table:

| Property | Advantage in Harsh Chemical Environments |

|---|---|

| Chemical Inertness | Resists corrosion from acids, solvents, and other aggressive chemicals. |

| Self-Lubrication | Low-friction operation without external lubricants that can fail. |

| Thermal Stability | Maintains performance across a wide temperature range. |

| Component Protection | Softer material helps prevent damage to mating shafts. |

Need a custom PTFE solution for your demanding application?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, labware, and custom bushes—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your components deliver unmatched chemical resistance and reliability, from prototype to high-volume production.

Contact our experts today to discuss how our PTFE solutions can solve your toughest chemical challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments