In short, ePTFE gaskets are ideal for the food and pharmaceutical industries because their chemically inert and non-toxic nature meets the world's most stringent safety standards. They provide a reliable seal without any risk of contaminating the product, reacting with cleaning agents, or compromising the sterile environment.

The core challenge in food and pharmaceutical sealing is twofold: the gasket must perform its mechanical duty flawlessly while also guaranteeing that it will not compromise product purity. ePTFE excels because it is one of the few materials that meets both needs without compromise.

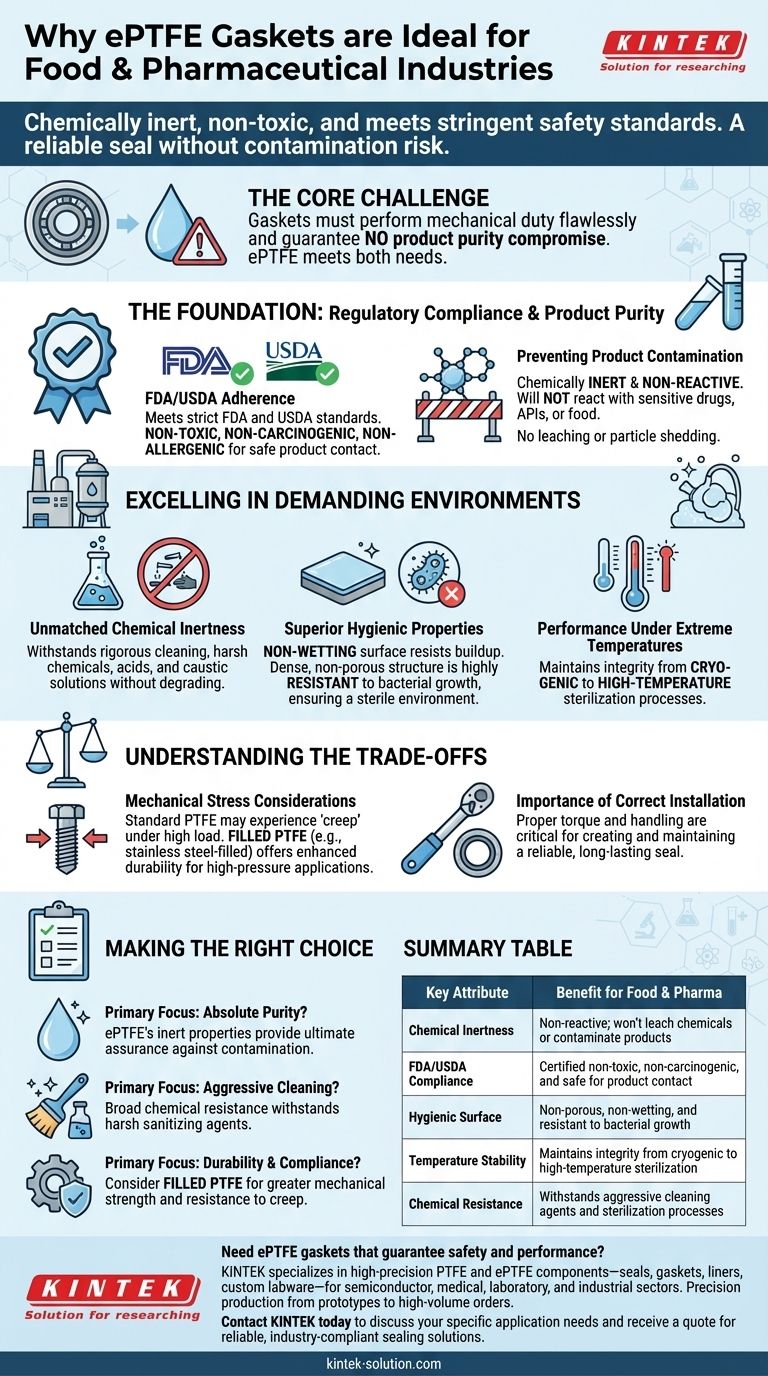

The Foundation: Regulatory Compliance and Product Purity

In industries where consumer safety is paramount, the materials used in processing equipment are subject to intense scrutiny. The choice of a gasket is not just about preventing leaks; it's about safeguarding the final product.

Adherence to FDA/USDA Standards

The most critical qualification for any material in these applications is compliance with regulatory bodies. ePTFE meets strict FDA (Food and Drug Administration) and USDA standards.

This compliance certifies that the material is non-toxic, non-carcinogenic, and non-allergenic, making it fundamentally safe for contact with food, beverages, and pharmaceutical compounds.

Preventing Product Contamination

A primary function of a gasket in these environments is to be completely unobtrusive to the process. ePTFE is chemically inert and non-reactive.

This means it will not react with sensitive drugs, active pharmaceutical ingredients (APIs), or food products. It does not leach chemicals or shed particles, ensuring the purity of the end product remains uncompromised.

Excelling in Demanding Operational Environments

Beyond its inherent purity, ePTFE is engineered to withstand the unique and harsh conditions found in food and pharmaceutical manufacturing facilities.

Unmatched Chemical Inertness

Processing equipment is subjected to rigorous cleaning and sterilization cycles involving harsh chemicals, acids, and caustic solutions. ePTFE's non-corrosive nature ensures it maintains its structural integrity and sealing capability despite repeated exposure to these agents.

Superior Hygienic Properties

Hygiene is non-negotiable. ePTFE's surface is non-wetting, which means it resists the buildup of process media and makes it exceptionally easy to clean and sanitize.

Crucially, its dense, non-porous structure is highly resistant to bacterial growth, a vital attribute for maintaining a sterile processing environment.

Performance Under Extreme Temperatures

From high-temperature sterilization processes to cryogenic applications, ePTFE gaskets maintain their integrity and sealing properties across a wide temperature range. This stability ensures reliable performance throughout various manufacturing stages.

Understanding the Trade-offs

While ePTFE is an exceptional material, no single solution is perfect for every scenario. A clear-eyed assessment of its properties is essential for proper application.

Considerations for Mechanical Stress

Standard PTFE can be susceptible to "creep" or cold flow under high mechanical loads and pressures. This can lead to a loss of seal over time.

For more demanding applications, filled PTFE variants, such as stainless steel-filled PTFE, are used. These combine PTFE's chemical resistance with enhanced durability and strength, providing a more robust solution for high-pressure systems.

The Importance of Correct Installation

The performance of any gasket, including ePTFE, is highly dependent on proper installation. Ensuring correct bolt torque and handling procedures is critical to creating and maintaining a reliable, long-lasting seal and preventing premature failure.

Making the Right Choice for Your Application

Selecting the correct gasket material is a critical decision that impacts both operational efficiency and product safety.

- If your primary focus is absolute product purity: ePTFE's inert, non-toxic, and non-contaminating properties provide the ultimate assurance against product interaction.

- If your primary focus is withstanding aggressive cleaning cycles: Its broad chemical resistance ensures the gasket will not degrade when exposed to harsh sanitizing agents.

- If your primary focus is combining durability with compliance: Consider a stainless steel-filled PTFE for applications requiring greater mechanical strength and resistance to creep.

Choosing an ePTFE gasket is an investment in both operational reliability and uncompromising safety.

Summary Table:

| Key Attribute | Benefit for Food & Pharma |

|---|---|

| Chemical Inertness | Non-reactive; won't leach chemicals or contaminate products |

| FDA/USDA Compliance | Certified non-toxic, non-carcinogenic, and safe for product contact |

| Hygienic Surface | Non-porous, non-wetting, and resistant to bacterial growth |

| Temperature Stability | Maintains integrity from cryogenic to high-temperature sterilization |

| Chemical Resistance | Withstands aggressive cleaning agents and sterilization processes |

Need ePTFE gaskets that guarantee safety and performance?

KINTEK specializes in manufacturing high-precision PTFE and ePTFE components—including seals, gaskets, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring your sealing solutions meet the strictest purity and compliance requirements.

Contact KINTEK today to discuss your specific application needs and receive a quote for reliable, industry-compliant sealing solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- When and by whom was PTFE discovered? A Tale of Accidental Innovation