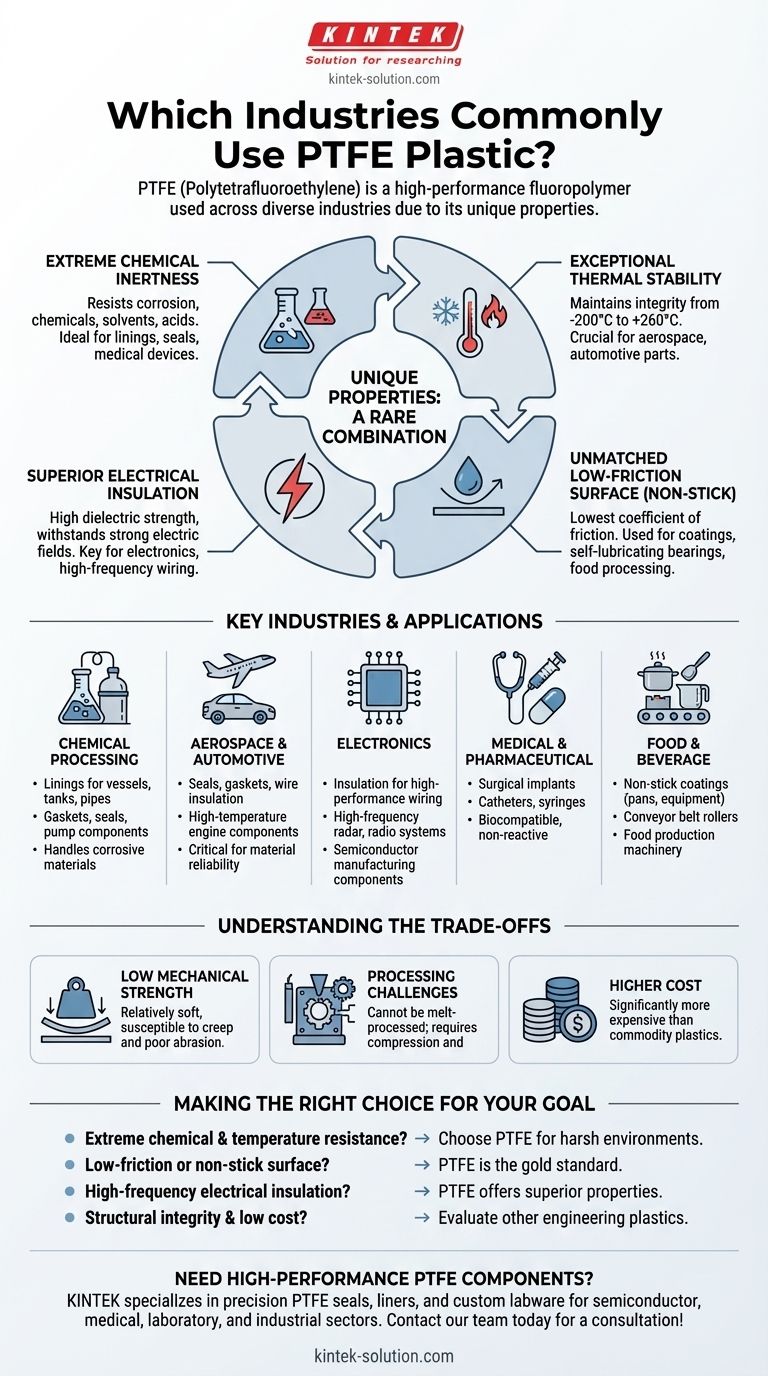

In short, Polytetrafluoroethylene (PTFE) is a high-performance fluoropolymer used across a remarkably diverse set of industries. Its most common applications are found in chemical processing, aerospace, electronics, medical and pharmaceutical manufacturing, and the food and beverage industry. The material's unique combination of properties makes it a critical problem-solver for demanding engineering challenges in each of these fields.

The widespread use of PTFE is not due to a single feature, but its rare combination of four key traits: extreme chemical inertness, high-temperature stability, excellent electrical insulation, and an incredibly low-friction, non-stick surface.

Why PTFE is a Go-To Material for Critical Applications

The value of PTFE becomes clear when you move beyond a simple list of industries and examine the specific properties that drive its adoption. Engineers select PTFE when other, more common plastics would fail under extreme conditions.

Extreme Chemical Inertness

PTFE is one of the most non-reactive substances known. It resists corrosion and degradation from nearly all industrial chemicals, solvents, and acids.

This makes it indispensable in the chemical processing industry for lining vessels, tanks, and pipes. It's also used for gaskets, seals, and pump components that are in constant contact with highly corrosive materials.

In the medical and pharmaceutical fields, this inertness is critical. Because it doesn't react with bodily fluids or tissues, it is used for surgical implants, catheters, and syringes.

Exceptional Thermal Stability

PTFE maintains its integrity over a vast temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This high-temperature resistance is crucial for the aerospace and automotive industries. It's used for seals, gaskets, and wire insulation in jet engines and other high-temperature engine components where material failure is not an option.

Superior Electrical Insulation

PTFE is an outstanding electrical insulator with a very high dielectric strength, meaning it can withstand strong electric fields without breaking down.

This property makes it a key material in the electronics industry. It is used as insulation for high-performance wiring and cables, especially in high-frequency applications like radar and radio systems, as well as for manufacturing components for semiconductors.

Unmatched Low-Friction Surface (Non-Stick)

PTFE has one of the lowest coefficients of friction of any solid material, which gives it its famous "non-stick" quality.

This is most famously leveraged in the kitchenware and food processing industries for non-stick coatings on pans and food production equipment like conveyor belt rollers.

Beyond the kitchen, this low-friction property is vital in industrial manufacturing for creating self-lubricating bearings, gears, and sliding plates in applications where external lubricants are impractical.

Understanding the Trade-offs

Despite its powerful advantages, PTFE is not a universal solution. An objective assessment requires acknowledging its limitations.

Low Mechanical Strength

PTFE is a relatively soft material. It is susceptible to "creep" (slow deformation under load) and has poor abrasion resistance compared to other engineering plastics.

Processing Challenges

PTFE cannot be melt-processed using conventional techniques like injection molding. It must be compressed and sintered—a more complex and often more costly manufacturing process.

Higher Cost

As a high-performance fluoropolymer, PTFE is significantly more expensive than commodity plastics like polyethylene or polypropylene. Its use must be justified by a specific performance requirement that other materials cannot meet.

Making the Right Choice for Your Goal

Your decision to use PTFE should be driven by the specific demands of your application.

- If your primary focus is extreme chemical and temperature resistance: PTFE is an elite choice for creating seals, linings, and components in harsh industrial or aerospace environments.

- If your primary focus is a low-friction or non-stick surface: PTFE remains the gold standard for everything from industrial bearings to food-grade coatings.

- If your primary focus is high-frequency electrical insulation: The unique dielectric properties of PTFE make it a superior choice for critical electronic and communications components.

- If your primary focus is structural integrity and low cost: You should evaluate other engineering plastics, as PTFE's mechanical weakness and higher price may make it unsuitable.

Understanding these core properties allows you to see PTFE not just as a material, but as a specific solution to a distinct set of engineering challenges.

Summary Table:

| Industry | Primary Use of PTFE | Key Property Leveraged |

|---|---|---|

| Chemical Processing | Linings, seals, gaskets | Extreme Chemical Inertness |

| Aerospace & Automotive | Seals, wire insulation | Exceptional Thermal Stability |

| Electronics | High-frequency wiring, semiconductors | Superior Electrical Insulation |

| Medical & Pharmaceutical | Implants, catheters, syringes | Biocompatibility & Chemical Inertness |

| Food & Beverage | Non-stick coatings, conveyor parts | Unmatched Low-Friction Surface |

Need High-Performance PTFE Components?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication ensures you get the exact solution for your demanding applications, from prototypes to high-volume orders.

Let us help you solve your toughest engineering challenges. Contact our team today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials