In most cases, you should not add external lubrication to PTFE components. While it seems counterintuitive, adding a lubricant can interfere with PTFE’s natural, self-lubricating properties and often increases friction and wear over time. Additional lubrication is only beneficial in very specific, demanding applications, and almost always involves using a dry lubricant.

The core principle to understand is that PTFE (Teflon) creates a low-friction surface by transferring a microscopic film of its own material onto the mating surface. Applying an external wet lubricant, like oil or grease, can block this transfer process, ultimately undermining the component's performance.

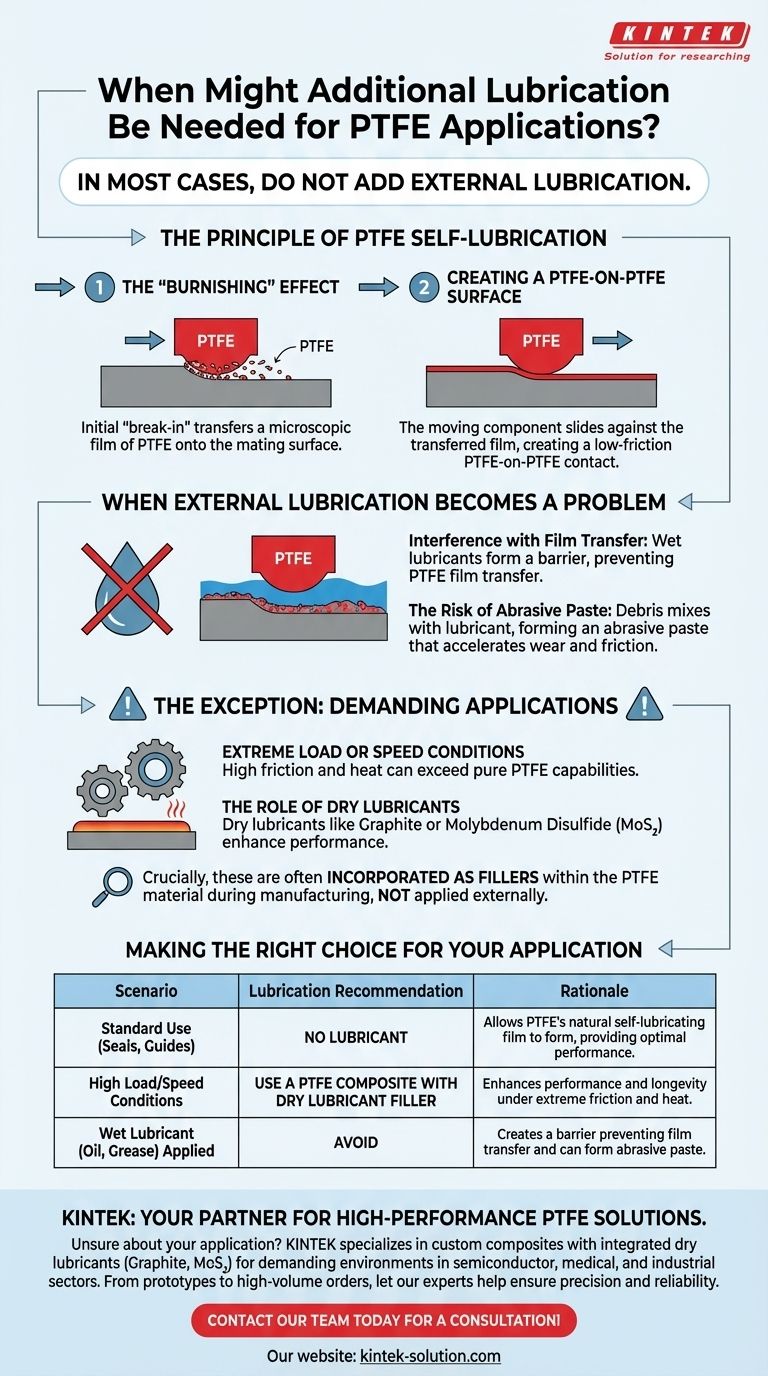

The Principle of PTFE Self-Lubrication

The "Burnishing" Effect

PTFE’s effectiveness comes from an initial "break-in" or burnishing period. As the component moves against a mating surface, a very thin, invisible film of PTFE is transferred onto that surface.

Creating a PTFE-on-PTFE Surface

Once this film is established, the moving component is no longer sliding against the original material (e.g., steel) but against the transferred film of PTFE. This PTFE-on-PTFE contact is what creates the material’s famously low coefficient of friction.

When External Lubrication Becomes a Problem

Interference with Film Transfer

The primary issue with adding a liquid lubricant (oil or grease) is that it forms a barrier film on the mating surface. This barrier physically prevents the transfer of the PTFE film, defeating the material's primary lubricating mechanism.

The Risk of Abrasive Paste

Over time, microscopic particles of the PTFE component will naturally wear away. If a wet lubricant is present, this debris can mix with the oil or grease. This mixture can form an abrasive paste, which dramatically accelerates wear and increases friction.

The Exception: Demanding Applications

Extreme Load or Speed Conditions

In certain high-load or high-speed applications, the friction and heat generated can exceed what pure PTFE can handle. In these scenarios, the self-lubricating film may not form quickly or durably enough.

The Role of Dry Lubricants

For these demanding cases, a dry lubricant like graphite or molybdenum disulfide (MoS₂) may be used to enhance performance and longevity.

Crucially, these are often incorporated as fillers within the PTFE material itself during manufacturing, creating a composite material. They are not typically applied externally to a pure PTFE part.

Understanding the Trade-offs

The decision to lubricate is a trade-off between trusting an inherent material property and attempting to augment it for an extreme use case.

For Most Applications: No Lubricant is Best

For the vast majority of uses, including gaskets, seals, and standard guides, PTFE is designed to be used without any lubrication. Its non-stick, low-friction properties are sufficient. Adding a lubricant introduces a significant risk of failure for no real benefit.

PTFE as a Lubricant

It is important to distinguish between lubricating a PTFE part and using PTFE as an ingredient in a lubricant. Products like PTFE-enhanced bicycle chain lube use suspended PTFE particles to reduce friction. This is a completely different context from applying lubricant to a solid PTFE component.

Making the Right Choice for Your Application

- If your primary focus is standard sealing or sliding: Trust the material's inherent properties. Do not apply any external lubricant.

- If your primary focus is performance under extreme loads or temperatures: Select a specialized PTFE composite that includes an integrated dry lubricant filler like graphite, MoS₂, or glass fiber.

- If your primary focus is lubricating general machinery (like a chain): Use a lubricant product that is specifically formulated with PTFE as an additive, rather than applying a generic lubricant to a solid PTFE part.

Ultimately, the most reliable approach is to allow PTFE to function exactly as it was designed: on its own.

Summary Table:

| Scenario | Lubrication Recommendation | Rationale |

|---|---|---|

| Standard Use (Seals, Guides) | No Lubricant | Allows PTFE's natural self-lubricating film to form, providing optimal performance. |

| High Load/Speed Conditions | Use a PTFE Composite with Dry Lubricant Filler | Enhances performance and longevity under extreme friction and heat. |

| Wet Lubricant (Oil, Grease) Applied | Avoid | Creates a barrier that prevents PTFE film transfer and can form an abrasive paste. |

Unsure if your PTFE application requires special lubrication? The wrong choice can lead to premature failure. KINTEK specializes in manufacturing high-performance PTFE components, including custom composites with integrated dry lubricants like graphite or MoS₂ for demanding environments in the semiconductor, medical, and industrial sectors. Let our experts help you select or fabricate the perfect PTFE solution—from prototypes to high-volume orders—ensuring precision and reliability. Contact our team today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech