In short, a thicker Teflon lip seal design is specifically used for applications where wear is expected to be high, particularly in unlubricated or "dry running" conditions. This design intentionally provides more sacrificial material to slowly wear away over time, thereby extending the operational life of the seal in harsh environments where a standard seal would fail prematurely.

The decision to use a thicker Teflon lip seal is a deliberate trade-off. You gain a significantly longer service life in high-wear, unlubricated applications at the cost of potentially higher friction and reduced high-speed capability.

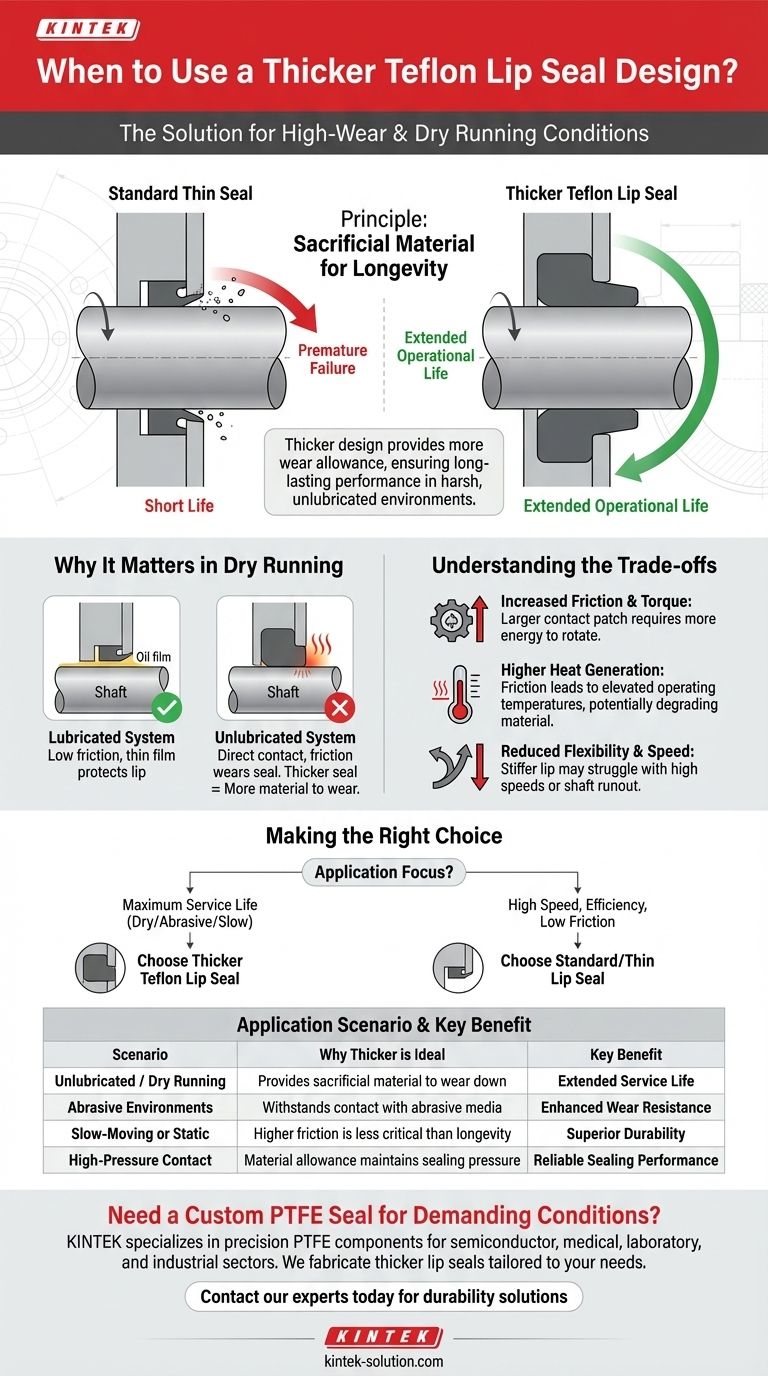

The Principle: Sacrificial Material for Longevity

The core concept behind a thicker seal lip is straightforward: it serves as a wear allowance. In demanding applications, the seal material is designed to be consumed over its lifespan, and having more material simply means it lasts longer.

Why Thickness Matters in Unlubricated Systems

In a well-lubricated system, a thin film of oil separates the seal lip from the rotating shaft, dramatically reducing friction and wear.

When lubrication is absent, the seal lip is in direct, dry contact with the shaft surface. This direct contact generates friction and causes the seal material to physically abrade, much like an eraser on paper.

A thicker seal design provides a greater volume of this "sacrificial" material. This ensures that even as the lip wears down, it can maintain the necessary contact pressure to create an effective seal for a longer period.

Extending Life in High-Wear Environments

High wear isn't just caused by a lack of lubrication. It can also be accelerated by abrasive media, rough shaft finishes, or high contact pressures.

In these cases, a standard, thin seal lip would wear through quickly, leading to leakage and premature system failure. The thicker design directly counters this failure mode by building in the required wear resistance.

Understanding the Trade-offs

Choosing a thicker seal is not a universal solution. This design choice comes with inherent compromises that make it unsuitable for certain applications.

Increased Friction and Torque

A thicker, and often wider, seal lip creates a larger contact patch on the shaft. This increased surface area results in higher frictional drag.

This means more energy, or torque, is required to rotate the shaft, which can be a critical issue in low-power or energy-efficient systems.

Higher Heat Generation

Friction generates heat. The increased friction from a thicker seal lip will inevitably lead to higher operating temperatures at the sealing point.

Excessive heat can degrade the seal material, damage the shaft, or break down any minimal lubrication that might be present, further accelerating wear.

Reduced Flexibility and Speed Capability

A thicker lip is inherently stiffer than a thinner one. This reduced flexibility can be a problem in high-speed applications.

A less flexible seal may struggle to follow minor shaft imperfections or runout (wobble), potentially leading to a compromised seal. For this reason, high-speed dynamic seals often feature very thin, flexible, and responsive lips.

Making the Right Choice for Your Application

The optimal seal design depends entirely on the specific demands of your system. You must balance the need for durability against performance requirements like speed and efficiency.

- If your primary focus is maximum service life in a dry, slow-moving, or abrasive system: A thicker Teflon lip seal is the correct engineering choice.

- If your primary focus is high-speed rotation, energy efficiency, or low-friction operation: A standard or thin-lip seal design will deliver superior performance.

Ultimately, seal thickness is a critical design variable that directly balances wear resistance against frictional and dynamic performance.

Summary Table:

| Application Scenario | Why a Thicker Seal is Ideal | Key Benefit |

|---|---|---|

| Unlubricated / Dry Running | Provides sacrificial material to wear down over time. | Extended Service Life |

| Abrasive Environments | Withstands contact with abrasive media or rough surfaces. | Enhanced Wear Resistance |

| Slow-Moving or Static Applications | Higher friction is less critical than longevity. | Superior Durability |

| High-Pressure Contact | Built-in material allowance maintains sealing pressure. | Reliable Sealing Performance |

Need a Custom PTFE Seal for Demanding Conditions?

If your application involves high wear, abrasive media, or dry-running conditions, the right seal design is critical. KINTEK specializes in manufacturing precision PTFE components, including custom lip seals, for the semiconductor, medical, laboratory, and industrial sectors.

We can fabricate a thicker lip seal tailored to your specific requirements, balancing wear resistance with performance to maximize your equipment's lifespan.

Contact our experts today to discuss your application and receive a solution designed for durability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments