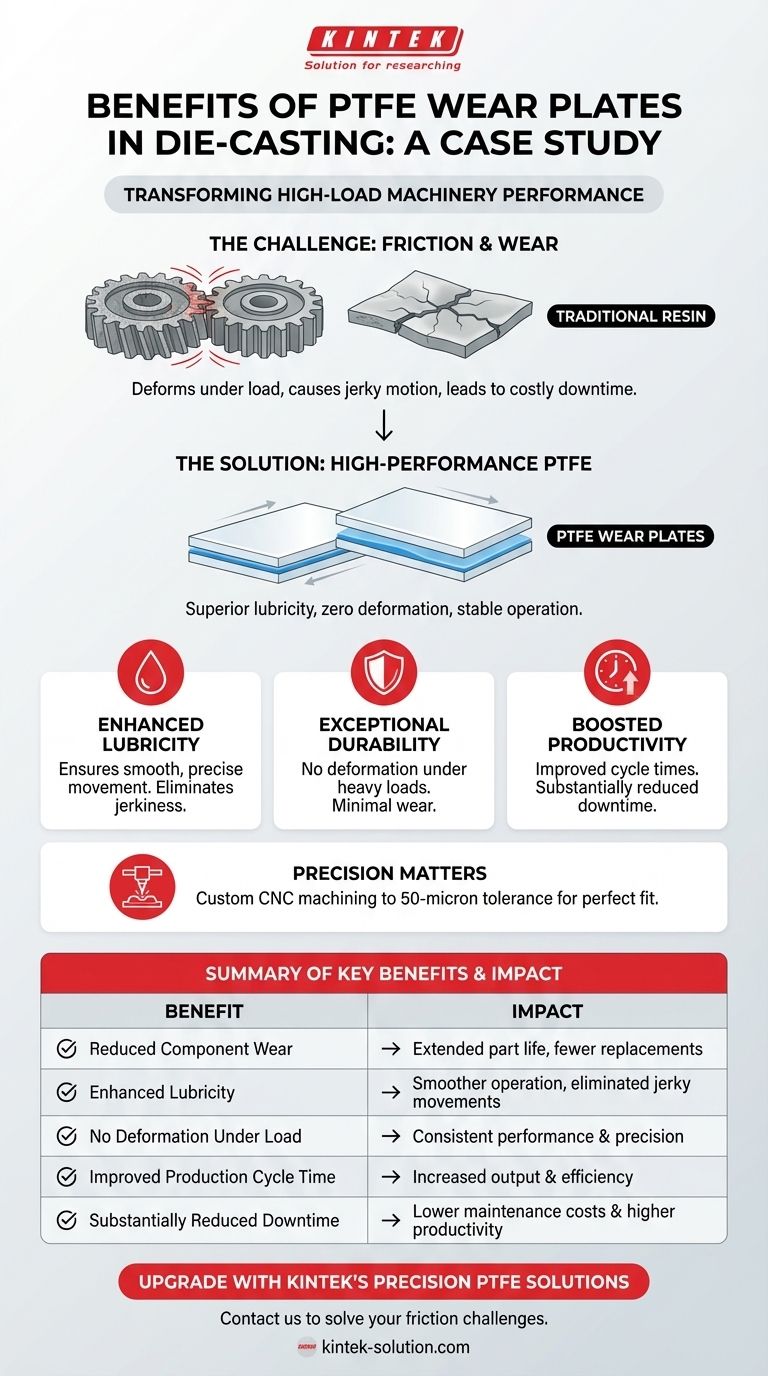

In the die-casting industry, the primary benefits of using PTFE wear plates were a significant reduction in component wear, enhanced lubricity for smoother machine operation, and improved production cycle times. These plates demonstrated exceptional stability by not deforming under heavy loads, which eliminated jerky movements and substantially reduced operational downtime compared to traditional resin plates.

The core issue in high-load industrial machinery is the constant battle against friction and wear, which leads to inefficiency and costly downtime. The case study demonstrates that PTFE wear plates are not just a component replacement, but a strategic upgrade that directly enhances machine longevity, precision, and overall productivity.

The Core Problem: Friction in High-Load Machinery

In demanding environments like die-casting, machinery components are subjected to immense pressure and continuous movement. This creates significant friction and wear on moving parts.

The Failure of Traditional Materials

Traditional materials, such as standard resin plates, often struggle in these conditions. They can deform under load, wear out quickly, and lead to inconsistent, jerky motions that compromise both the machinery and the quality of the final product.

The Consequence of Inefficiency

This rapid degradation results in frequent maintenance, costly downtime for replacements, and slower production cycles. The constant need for lubrication and part changes becomes a significant operational bottleneck.

How PTFE Delivers Superior Performance

Polytetrafluoroethylene (PTFE) addresses these fundamental challenges through its unique material properties. It provides a stable, low-friction solution that transforms machine performance.

Enhanced Lubricity and Smooth Operation

PTFE possesses an extremely low coefficient of friction. This inherent lubricity ensures that moving parts glide smoothly over one another, effectively eliminating the jerkiness common with other materials. This leads to more precise and predictable machine operation.

Exceptional Durability Under Load

A critical finding was that the PTFE plates did not deform even under the heavy, repetitive loads of die-casting equipment. This structural integrity ensures consistent performance and results in minimal wear over extended periods, far outlasting the previous resin plates.

Direct Impact on Productivity

The combination of smooth operation and durability translates directly to bottom-line benefits. Smoother movements allow for an improved cycle time, meaning more units can be produced in the same amount of time. Furthermore, the extended lifespan of the plates drastically reduced downtime associated with maintenance and part replacement.

Understanding the Practical Considerations

While highly effective, implementing PTFE wear plates requires attention to manufacturing precision to unlock their full potential.

The Role of Precision Machining

Achieving the desired performance is dependent on expert fabrication. The references note that a CNC vertical milling centre is used to machine custom groove patterns and hole dimensions into the plates.

Achieving Necessary Tolerance

PTFE can be machined to a maximum tolerance of 50 microns. This level of precision is crucial for ensuring a perfect fit and function, and it is considered highly acceptable for the demands of most industrial applications, including die-casting.

Making the Right Choice for Your Goal

The decision to integrate PTFE wear plates should be based on your specific operational priorities.

- If your primary focus is maximizing uptime and reliability: The superior durability and minimal wear of PTFE directly reduce maintenance cycles and costly production halts.

- If your primary focus is improving production speed and quality: The enhanced lubricity provides smoother, more consistent machine motion, leading to faster cycles and more precise output.

Ultimately, adopting PTFE wear plates is a proven method for upgrading mechanical systems to achieve a higher standard of operational excellence.

Summary Table:

| Benefit | Impact |

|---|---|

| Reduced Component Wear | Extended part life, fewer replacements |

| Enhanced Lubricity | Smoother machine operation, eliminated jerky movements |

| No Deformation Under Load | Consistent performance and precision |

| Improved Production Cycle Time | Increased output and efficiency |

| Substantially Reduced Downtime | Lower maintenance costs and higher productivity |

Ready to eliminate downtime and boost your production efficiency?

This case study demonstrates the transformative power of high-performance PTFE components. KINTEK specializes in precision-manufactured PTFE seals, liners, labware, and custom components like wear plates for the semiconductor, medical, laboratory, and industrial sectors.

We deliver the durability and precision you need to enhance machine longevity and productivity. From custom prototypes to high-volume orders, our expertise ensures a perfect fit for your demanding applications.

Contact KINTEK today to discuss how our PTFE solutions can solve your specific friction and wear challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials