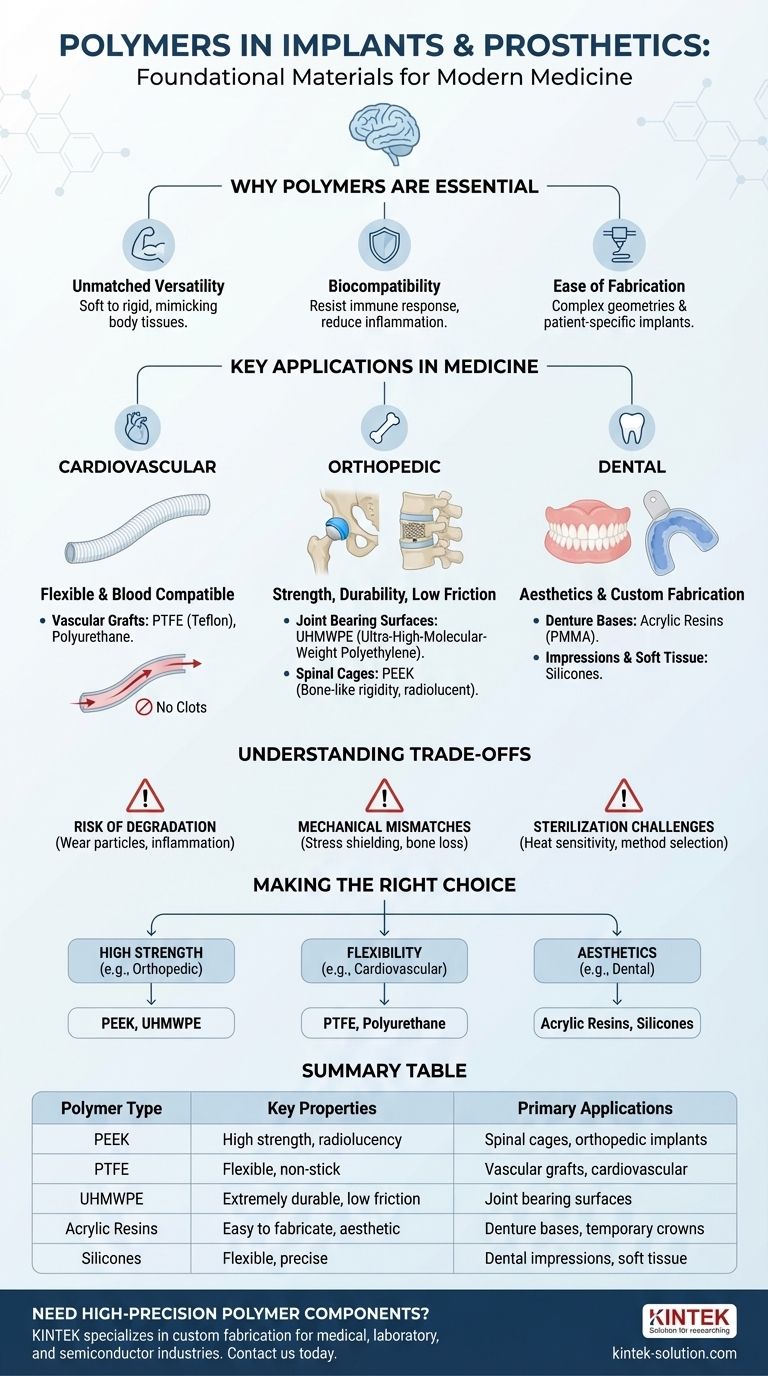

In modern medicine, polymers are foundational materials used in a vast array of implants and prosthetics due to their versatility. Key applications include flexible vascular grafts made from materials like PTFE, high-strength orthopedic components using PEEK, and various elements in soft tissue reconstruction and dental devices.

The core principle is not simply using a polymer, but selecting a specific polymer whose unique mechanical and chemical properties—such as flexibility, strength, or inertness—precisely match the biological function of the intended implant.

Why Polymers are Essential in Biomedical Devices

Polymers offer a combination of properties that metals and ceramics cannot easily replicate. This makes them indispensable for interacting with the complex systems of the human body.

Unmatched Versatility

Polymers can be engineered to be incredibly diverse. They can be formulated to be as soft and flexible as human tissue or as rigid and strong as bone.

This allows engineers to create devices that mimic the function of the body part they are replacing or supporting, from a flexible heart valve to a rigid spinal cage.

Biocompatibility

Biocompatibility is the ability of a material to perform its desired function without eliciting an undesirable local or systemic response from the body.

Many medical-grade polymers, such as Polyetheretherketone (PEEK) and Polytetrafluoroethylene (PTFE), are highly biocompatible. They are designed to resist provoking an immune response, reducing the risk of inflammation and implant rejection.

Ease of Fabrication

Polymers are highly adaptable to advanced manufacturing processes. They can be molded into complex geometries, spun into fine fibers for grafts and sutures, or used in 3D printing to create patient-specific implants.

This ease of fabrication is critical for producing the intricate shapes required for many medical devices.

Key Applications of Polymers in Implants

Different polymers are chosen for specific applications based on the demands of the biological environment.

Cardiovascular Systems

In the cardiovascular system, materials must be flexible and resist blood clotting.

Vascular grafts, which replace or bypass diseased arteries, are commonly made from PTFE (also known as Teflon) or polyurethane. These materials provide a smooth, non-stick surface that minimizes the risk of thrombosis (blood clot formation).

Orthopedic Solutions

Orthopedics demands materials with exceptional strength, durability, and low friction.

While the main structural components of hip or knee joints are metal, the bearing surface or "socket" is almost always made of Ultra-High-Molecular-Weight Polyethylene (UHMWPE). This polymer provides a low-friction surface that can withstand millions of cycles of movement.

For applications like spinal fusion cages, PEEK is often used. It offers bone-like rigidity and is transparent to X-rays, allowing surgeons to better assess the surgical site post-operation.

Dental Applications

While the core dental implant that fuses with the jawbone is typically titanium (a metal), polymers are essential for other components.

Denture bases are made from acrylic resins like PMMA, and temporary crowns often use similar materials. Flexible polymers like silicones are also critical for making precise dental impressions.

Understanding the Trade-offs

No material is perfect. The selection of a polymer always involves balancing its benefits against potential drawbacks.

The Risk of Degradation

Over long periods, some polymers can degrade within the body. This process can release microscopic wear particles.

In the case of joint replacements, these wear particles can sometimes lead to an inflammatory response that causes bone loss (osteolysis) around the implant, potentially leading to loosening.

Mechanical Mismatches

If an implant is significantly stiffer than the surrounding bone, it can carry too much of the mechanical load.

This phenomenon, known as "stress shielding," can cause the adjacent bone to weaken and deteriorate over time because it is no longer being adequately stimulated.

Sterilization Challenges

Some polymers cannot withstand the high temperatures of steam sterilization (autoclaving), which is a common hospital practice.

These materials must be sterilized using other methods, such as gamma radiation or ethylene oxide gas, which can sometimes alter the polymer's long-term mechanical properties.

Making the Right Choice for Your Goal

The optimal polymer is entirely dependent on the specific medical challenge you are trying to solve.

- If your primary focus is high-strength, load-bearing applications: Your best options are highly durable polymers like PEEK and UHMWPE, which are standards in orthopedic implants.

- If your primary focus is flexibility and blood compatibility: You should consider fluoropolymers like PTFE or elastomers like polyurethane for cardiovascular devices.

- If your primary focus is aesthetics and custom fabrication: Acrylic resins and silicones offer the design freedom needed for dental prosthetics and soft tissue applications.

Ultimately, the success of any polymeric implant depends on a precise alignment between the material's properties and the body's complex biological demands.

Summary Table:

| Polymer Type | Key Properties | Primary Applications |

|---|---|---|

| PEEK | High strength, bone-like rigidity, radiolucency | Spinal cages, orthopedic implants |

| PTFE (Teflon) | Flexible, non-stick, biocompatible | Vascular grafts, cardiovascular devices |

| UHMWPE | Extremely durable, low friction | Bearing surfaces in joint replacements |

| Acrylic Resins (PMMA) | Easy to fabricate, aesthetic | Denture bases, temporary crowns |

| Silicones | Flexible, precise | Dental impressions, soft tissue prosthetics |

Need High-Precision Polymer Components for Your Medical Device?

At KINTEK, we specialize in the custom fabrication of high-performance polymer components, including PTFE seals, liners, and labware, essential for demanding applications in the medical, laboratory, and semiconductor industries.

Our expertise in precision production ensures your devices meet the stringent requirements for biocompatibility and performance. Whether you need prototypes or high-volume orders, we deliver components that align with your exact specifications.

Contact us today to discuss how our custom polymer solutions can enhance your next medical innovation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications