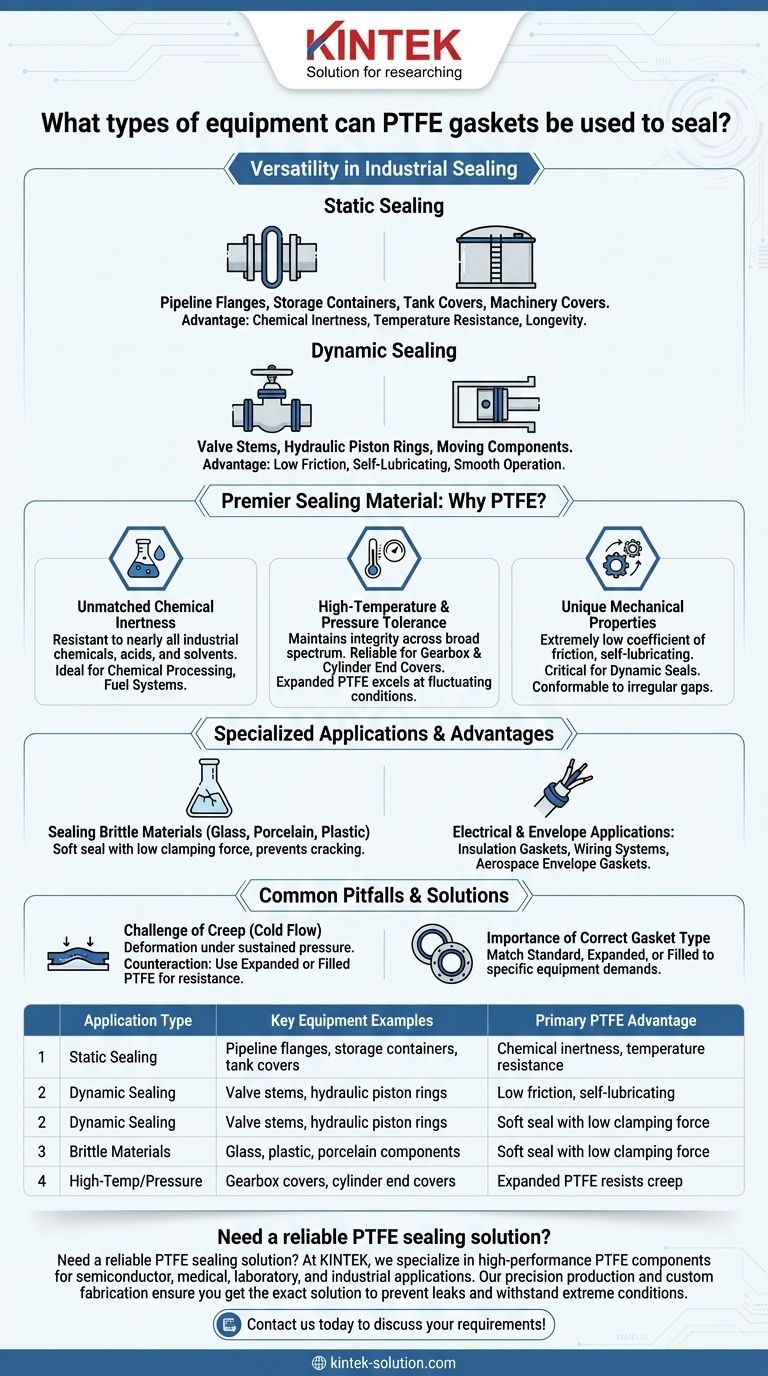

To be direct, PTFE gaskets are used to seal an extremely wide range of industrial and mechanical equipment. Their applications span from static seals in pipeline flanges, fuel tank covers, and storage containers to dynamic seals in valve stems and hydraulic piston rings. They are particularly effective in sealing brittle materials like glass and plastic.

The versatility of PTFE gaskets isn't defined by the equipment they seal, but by the challenging conditions they overcome. Their unique combination of chemical inertness, temperature resistance, and mechanical properties makes them a default solution for preventing leaks in the most demanding industrial environments.

Why PTFE is a Premier Sealing Material

The reason PTFE is so widely used comes down to a set of core properties that make it uniquely suited for creating a reliable barrier between two surfaces. Understanding these characteristics explains its presence in everything from chemical plants to aerospace components.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals, acids, and solvents. This makes it the ideal sealing material for equipment in chemical processing, fuel systems, and other applications involving corrosive substances.

This property ensures the gasket will not degrade or contaminate the medium it is sealing, guaranteeing both operational safety and product purity.

High-Temperature and Pressure Tolerance

PTFE gaskets maintain their integrity and sealing capability across a broad spectrum of temperatures and pressures. This allows them to be used reliably in high-stress applications like gearbox end covers and cylinder end covers.

Expanded PTFE, in particular, excels at maintaining a strong seal under fluctuating high-temperature and high-pressure conditions due to its excellent elasticity.

Unique Mechanical Properties

With an extremely low coefficient of friction, PTFE is self-lubricating. This is critical for dynamic seals in equipment with moving parts, such as valve stems and hydraulic piston rings, as it ensures smooth movement and prevents wear.

Its flexibility and plasticity allow it to conform perfectly to sealing surfaces, which is especially important for sealing large-diameter containers or irregular gaps.

Key Applications by Equipment Type

While the properties define its potential, the true scope of PTFE's utility is seen in its diverse applications across various types of equipment and materials.

Static Sealing in Flanges and Containers

The most common use for PTFE gaskets is creating a static, leak-proof seal between two stationary parts. This includes pipeline flanges, storage containers, tanks, and various machinery covers.

In these roles, the gasket's longevity and resistance to aging reduce maintenance needs and prevent costly operational inefficiencies.

Sealing Brittle and Non-Metallic Materials

PTFE is exceptionally effective for sealing connections involving brittle materials like glass, porcelain, graphite, and plastic.

Because it is soft and can create a tight seal with low clamping force, it prevents the cracking or damage that a harder gasket material could cause to these fragile components.

Dynamic Sealing in Moving Components

In applications where parts move relative to each other, PTFE's low friction is essential. It is used to create reliable seals in valve stems and hydraulic piston rings, preventing leaks while allowing for smooth, unimpeded operation.

Specialized Electrical and Envelope Applications

Beyond fluid sealing, PTFE's properties make it suitable for insulation gaskets and sealing in wiring systems. Furthermore, PTFE envelope gaskets are used to seal large openings in plumbing and aerospace, providing a robust barrier against contaminants.

Common Pitfalls to Avoid

Despite its advantages, PTFE is not a universal solution. Understanding its primary limitation is critical for successful implementation and avoiding seal failure.

The Challenge of Creep (Cold Flow)

The main drawback of standard PTFE is its tendency to "creep" or cold flow. Under sustained pressure and temperature, the material can slowly deform and flow out from the flange, leading to a loss of bolt torque and potential leaks.

This characteristic must be accounted for during the design and installation of the sealed joint to ensure long-term reliability.

The Importance of Correct Gasket Type

To counteract creep, various forms of PTFE have been developed. Expanded PTFE and filled PTFE (which includes materials like glass or carbon) are engineered to resist cold flow and maintain sealing integrity under higher pressures.

Choosing the right type—standard, expanded, or filled—is critical for matching the gasket's performance to the specific demands of the equipment.

Making the Right Choice for Your Application

Selecting the correct PTFE gasket requires matching the material's properties to your primary operational goal.

- If your primary focus is sealing aggressive chemicals or fuels: Standard PTFE provides the ultimate chemical resistance for static seals in flanges and containers.

- If you are sealing delicate materials like glass or plastic: Expanded PTFE is ideal due to its high compressibility, creating a tight seal with low bolt load.

- If your application involves moving parts like valve stems: A PTFE-based seal is critical for its low friction to ensure smooth operation and long life.

- If you need to seal a high-pressure or high-temperature flange: Use a filled or expanded PTFE gasket specifically designed to resist cold flow and maintain a reliable seal.

By understanding the distinct advantages of PTFE, you can confidently select the precise sealing solution to ensure the safety and efficiency of your equipment.

Summary Table:

| Application Type | Key Equipment Examples | Primary PTFE Advantage |

|---|---|---|

| Static Sealing | Pipeline flanges, storage containers, tank covers | Chemical inertness, temperature resistance |

| Dynamic Sealing | Valve stems, hydraulic piston rings | Low friction, self-lubricating |

| Brittle Materials | Glass, plastic, porcelain components | Soft seal with low clamping force |

| High-Temp/Pressure | Gearbox covers, cylinder end covers | Expanded PTFE resists creep |

Need a reliable PTFE sealing solution for your equipment?

At KINTEK, we specialize in manufacturing high-performance PTFE components (seals, gaskets, liners, and labware) for semiconductor, medical, laboratory, and industrial applications. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get the exact sealing solution to prevent leaks, resist chemicals, and withstand extreme conditions.

Contact us today (#ContactForm) to discuss your specific requirements and let our experts help you select or custom-design the perfect PTFE gasket for your application!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers