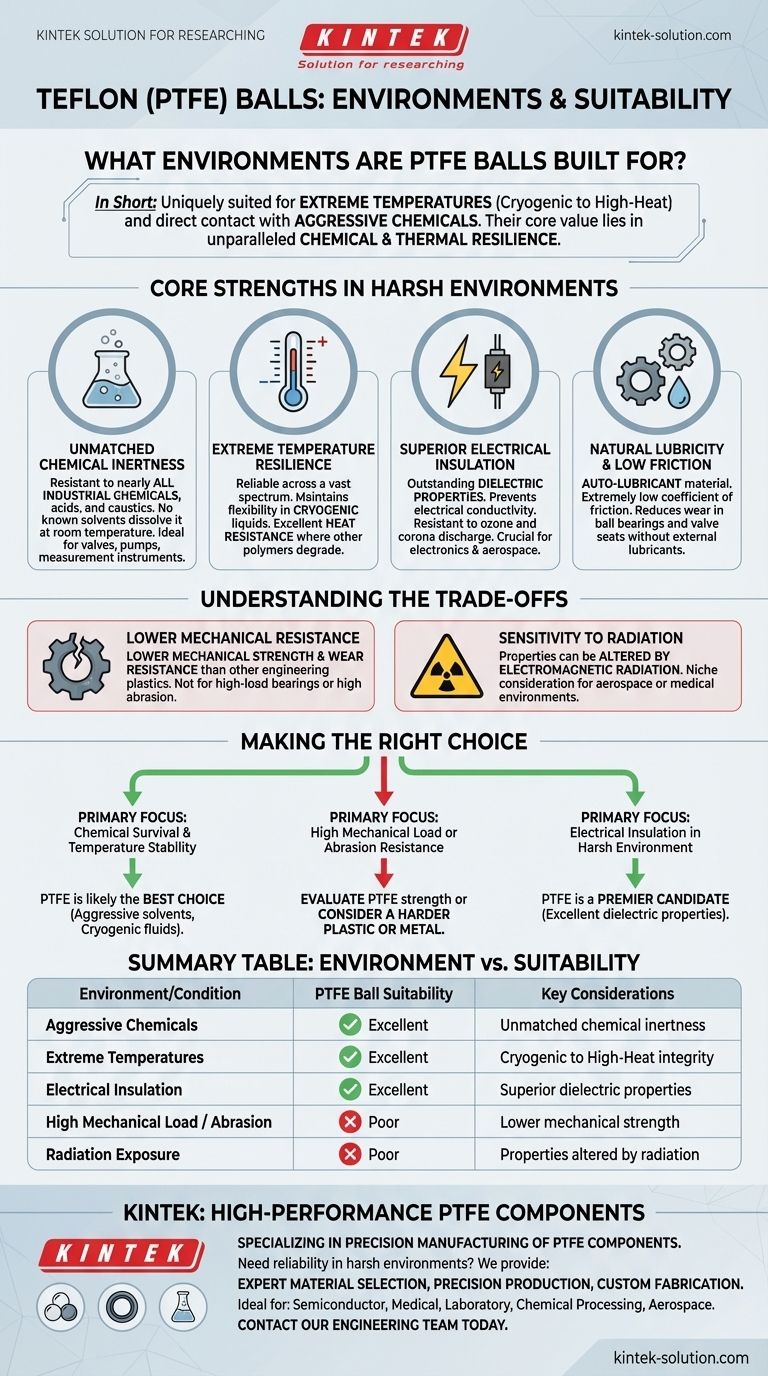

In short, Teflon (PTFE) balls are uniquely suited for environments characterized by extreme temperatures, from cryogenic liquids to high-heat applications, and for direct contact with aggressive chemicals like acids and caustics. Their combination of chemical inertness, thermal stability, and electrical insulation makes them a default choice for specialized industrial, medical, and aerospace applications where other materials would quickly fail.

The core value of PTFE lies in its unparalleled chemical and thermal resilience. However, this exceptional stability comes with a critical trade-off: it possesses lower mechanical strength and wear resistance compared to many other engineering plastics.

The Core Strengths of PTFE in Harsh Environments

To understand where PTFE balls thrive, we must first examine their fundamental properties. These characteristics make them a specialized solution, not a general-purpose one.

Unmatched Chemical Inertness

PTFE is famously resistant to nearly all industrial chemicals. There are no known solvents that can dissolve it at room temperature, and it stands up to the most aggressive acids and caustics.

This makes PTFE balls ideal for components in valves, pumps, and measurement instruments used in the chemical, foodstuff, and pharmaceutical industries, where contamination and corrosion are unacceptable.

Extreme Temperature Resilience

PTFE performs reliably across a vast temperature spectrum. It maintains its flexibility and structural integrity at cryogenic temperatures, making it suitable for apparatus handling liquefied gases.

Simultaneously, it has excellent heat resistance, allowing it to be used in high-temperature applications where other polymers would degrade.

Superior Electrical Insulation

PTFE possesses outstanding electrical insulating properties and dielectric stability. This makes it a critical material in the electronics and aerospace sectors for components that must prevent electrical conductivity.

Its resistance to ozone and corona discharge further enhances its reliability in electrical applications.

Natural Lubricity and Low Friction

PTFE is an auto-lubricant material with an extremely low coefficient of friction. This inherent "slipperiness" is valuable for ball bearings and valve seats, reducing the need for external lubricants and minimizing wear from sliding contact.

Understanding the Trade-offs

No material is perfect. While PTFE excels in chemical and thermal resistance, its limitations are primarily mechanical. Understanding these is crucial for proper application.

Lower Wear and Mechanical Resistance

The primary drawback of PTFE is its relatively low mechanical strength and wear resistance when compared to other engineering plastics. It is softer and more susceptible to deformation under high loads or in abrasive conditions.

This means it is not suitable for high-load bearings or applications where high abrasion is expected, unless it is used in a composite or filled form.

Sensitivity to Radiation

The properties of PTFE can be altered by exposure to certain types of electromagnetic radiation. This is a niche but important consideration for applications in specific aerospace or medical environments where such radiation is present.

Making the Right Choice for Your Application

Selecting PTFE should be a deliberate decision based on its unique strengths and weaknesses. Use the following guidelines to determine if it fits your project's primary goal.

- If your primary focus is chemical survival and temperature stability: PTFE is likely the best choice, especially for contact with aggressive solvents, acids, or cryogenic fluids.

- If your primary focus is high mechanical load or abrasion resistance: You must carefully evaluate if PTFE's strength is sufficient, or consider a harder plastic or metal component instead.

- If your primary focus is electrical insulation in a harsh environment: PTFE is a premier candidate due to its excellent dielectric properties combined with its thermal and chemical stability.

Ultimately, choosing PTFE is a choice for absolute resilience against chemical and thermal extremes, provided the mechanical demands of the application are moderate.

Summary Table:

| Environment/Condition | PTFE Ball Suitability | Key Considerations |

|---|---|---|

| Aggressive Chemicals (Acids, Caustics) | Excellent | Unmatched chemical inertness; resists nearly all solvents. |

| Extreme Temperatures (Cryogenic to High-Heat) | Excellent | Maintains integrity from very low to very high temperatures. |

| Electrical Insulation | Excellent | Superior dielectric properties; resists ozone and corona. |

| High Mechanical Load / Abrasion | Poor | Lower mechanical strength and wear resistance. |

| Radiation Exposure | Poor | Properties can be altered by certain electromagnetic radiation. |

Need High-Performance PTFE Components for Demanding Applications?

KINTEK specializes in the precision manufacturing of PTFE components, including balls, seals, liners, and custom labware. We understand the critical need for reliability in harsh environments.

We provide:

- Expert Material Selection: Guidance on whether PTFE or an alternative material is best suited for your specific mechanical, chemical, and thermal requirements.

- Precision Production: Components manufactured to exact specifications for reliable performance.

- Custom Fabrication: From initial prototypes to high-volume production runs, tailored to your needs.

Ideal for industries like: Semiconductor, Medical, Laboratory, Chemical Processing, and Aerospace.

Let us help you solve your most challenging application problems. Contact our engineering team today for a consultation!

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the overall benefits of spring-energized PTFE seals? Solve Extreme Sealing Challenges

- What is Dispersion PTFE used for? Creating Thin, High-Performance Coatings and Films

- What are PTFE washers made of? Unlocking the Power of Carbon-Fluorine Chemistry

- What are the advantages of PTFE-coated O-rings? Reduce Friction & Color-Code for Easy Assembly

- What is the significance of low surface adhesion in PTFE diaphragm valves for pharmaceutical research? Ensure Sample Integrity and Process Reliability

- What are the key advantages of PTFE rotary seals over traditional rubber seals? Superior Performance in Extreme Conditions

- What are the properties of stainless steel-filled PTFE? Enhance Load & Wear Resistance for Demanding Applications

- What additional benefits do PTFE rotary shaft seals offer? Achieve Superior Reliability in Extreme Conditions