The performance of PTFE bushings is significantly enhanced by incorporating specific additives or fillers. The most common choices are glass fibers, carbon, graphite, and molybdenum disulfide (MoS2). These materials are not simply mixed in; they are strategically chosen to augment PTFE's natural properties, dramatically improving its strength, wear resistance, and suitability for demanding applications.

While pure Polytetrafluoroethylene (PTFE) offers an exceptionally low coefficient of friction, its inherent softness and poor wear resistance limit its use under significant load or speed. Additives are the essential engineering solution that transforms PTFE from a slippery plastic into a high-performance bearing material.

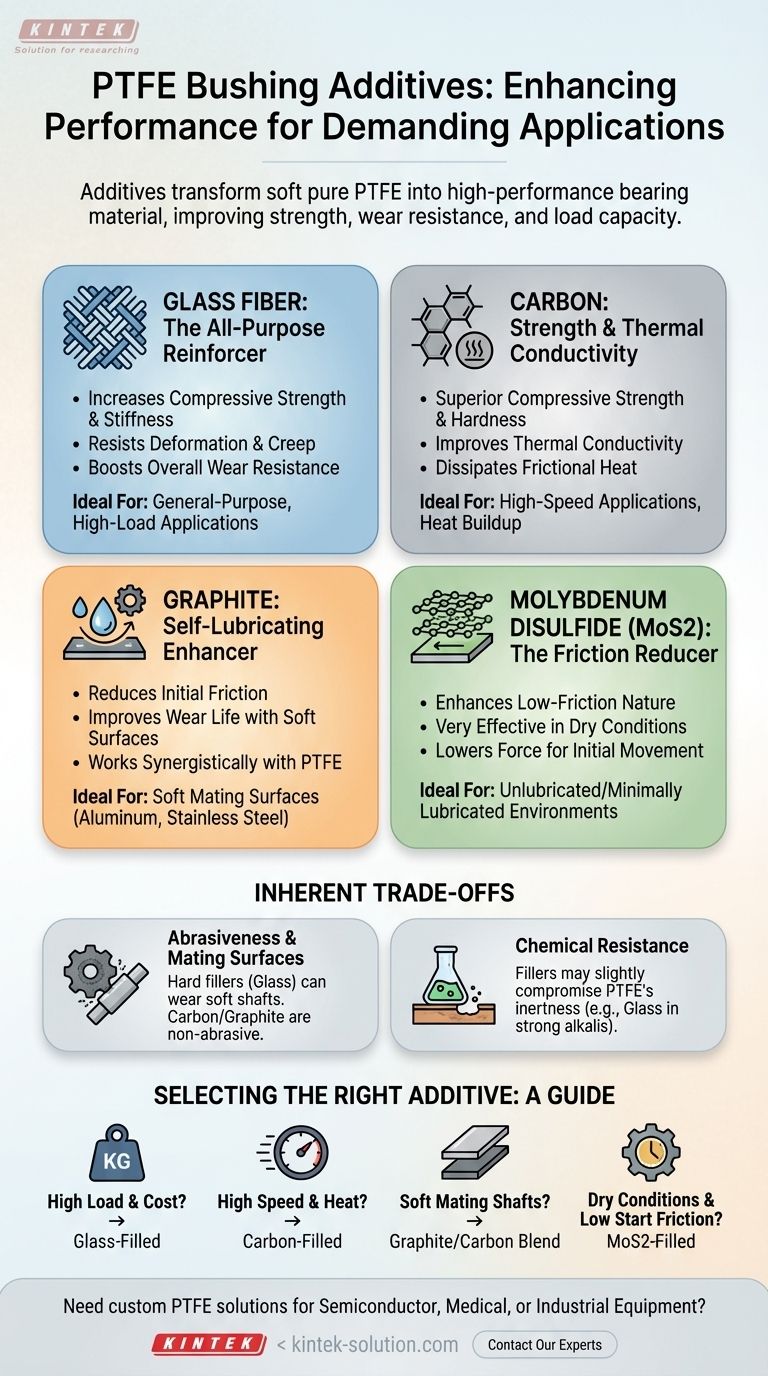

A Closer Look at Key PTFE Additives

Understanding the specific properties each additive imparts is critical for selecting the correct bushing. Each filler tailors the final material for a different set of operational demands.

Glass Fiber: The All-Purpose Reinforcer

Glass fiber is one of the most common fillers for PTFE. Its primary function is to improve the mechanical properties of the base material.

Adding glass significantly increases the compressive strength and stiffness of the bushing. This makes it far more resistant to deformation or "creep" under static loads. It also provides a major boost to overall wear resistance.

Carbon: For Strength and Thermal Conductivity

Carbon, often added in fiber or powder form, offers a distinct set of advantages over glass. It provides an even greater increase in compressive strength and hardness.

Crucially, carbon improves thermal conductivity. This allows the bushing to dissipate frictional heat more effectively, making carbon-filled PTFE an excellent choice for higher-speed applications where heat buildup is a primary cause of failure.

Graphite: The Self-Lubricating Enhancer

Graphite is a solid lubricant that works synergistically with PTFE. While PTFE is already slippery, graphite further reduces the initial coefficient of friction.

Its main benefit is improving wear life, particularly when the bushing is paired with softer mating surfaces like stainless steel or aluminum. It is often combined with other fillers, such as carbon, to create a blend with balanced properties.

Molybdenum Disulfide (MoS2): The Friction Reducer

Like graphite, Molybdenum Disulfide (MoS2) is a dry lubricant that enhances PTFE's low-friction nature.

MoS2 is particularly effective at reducing friction in applications where little to no external lubrication is present. It creates a highly effective lubricating film that significantly lowers the force required for initial movement (static friction).

Understanding the Inherent Trade-offs

Adding fillers to PTFE is a balancing act. Improving one property often comes at the expense of another, and these trade-offs are critical to consider during design.

Abrasiveness and Mating Surfaces

The hardness of the filler impacts the shaft material it runs against. Glass fibers are abrasive and can cause wear on softer shafts, such as those made from aluminum or certain grades of steel.

For applications involving soft shafts, carbon or graphite-filled PTFE are far better choices as they are non-abrasive and will not damage the mating surface.

Chemical Resistance

Pure PTFE is almost completely chemically inert. However, the introduction of fillers can slightly compromise this resistance.

Glass fibers, for example, can be attacked by strong alkaline solutions and hydrofluoric acid. While the bushing will still have excellent chemical resistance for most uses, this limitation must be considered in highly aggressive chemical environments.

The Coefficient of Friction

While additives like graphite and MoS2 can lower friction, hard structural fillers like glass and carbon can slightly increase the coefficient of friction compared to pure, virgin PTFE.

However, this minor increase in friction is almost always an acceptable trade-off for the massive gains in wear resistance and load-bearing capability.

Selecting the Right Additive for Your Application

The ideal additive is determined entirely by the operational demands of the bushing. Use the following points as a guide to make an informed decision.

- If your primary focus is high load capacity and cost-effectiveness: A glass-filled PTFE offers the best all-around improvement in strength and wear resistance for general-purpose applications.

- If your primary focus is high-speed rotational applications: A carbon-filled PTFE is the superior choice due to its ability to dissipate frictional heat.

- If your primary focus is pairing with soft metal shafts: A graphite-filled or carbon/graphite blend will prevent abrasion and extend the life of the entire assembly.

- If your primary focus is minimizing initial friction in dry conditions: A PTFE compound containing Molybdenum Disulfide (MoS2) will provide the necessary lubricity.

By matching the additive's properties to your application's challenges, you ensure the bushing is not just a component, but a precisely engineered solution.

Summary Table:

| Additive | Key Performance Enhancements | Ideal For |

|---|---|---|

| Glass Fiber | High compressive strength, stiffness, wear resistance | General-purpose, high-load applications |

| Carbon | Superior strength, hardness, thermal conductivity | High-speed applications with heat buildup |

| Graphite | Enhanced self-lubrication, reduced friction | Soft mating surfaces (aluminum, stainless steel) |

| Molybdenum Disulfide (MoS2) | Very low initial friction in dry conditions | Unlubricated or minimally lubricated environments |

Need a custom PTFE bushing solution for your semiconductor, medical, or industrial equipment?

At KINTEK, we specialize in precision manufacturing of PTFE components, including custom-filled bushings tailored to your specific load, speed, and environmental requirements. We offer custom fabrication from prototypes to high-volume orders, ensuring optimal performance and longevity for your critical applications.

Contact our experts today to discuss your project and receive a tailored solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications