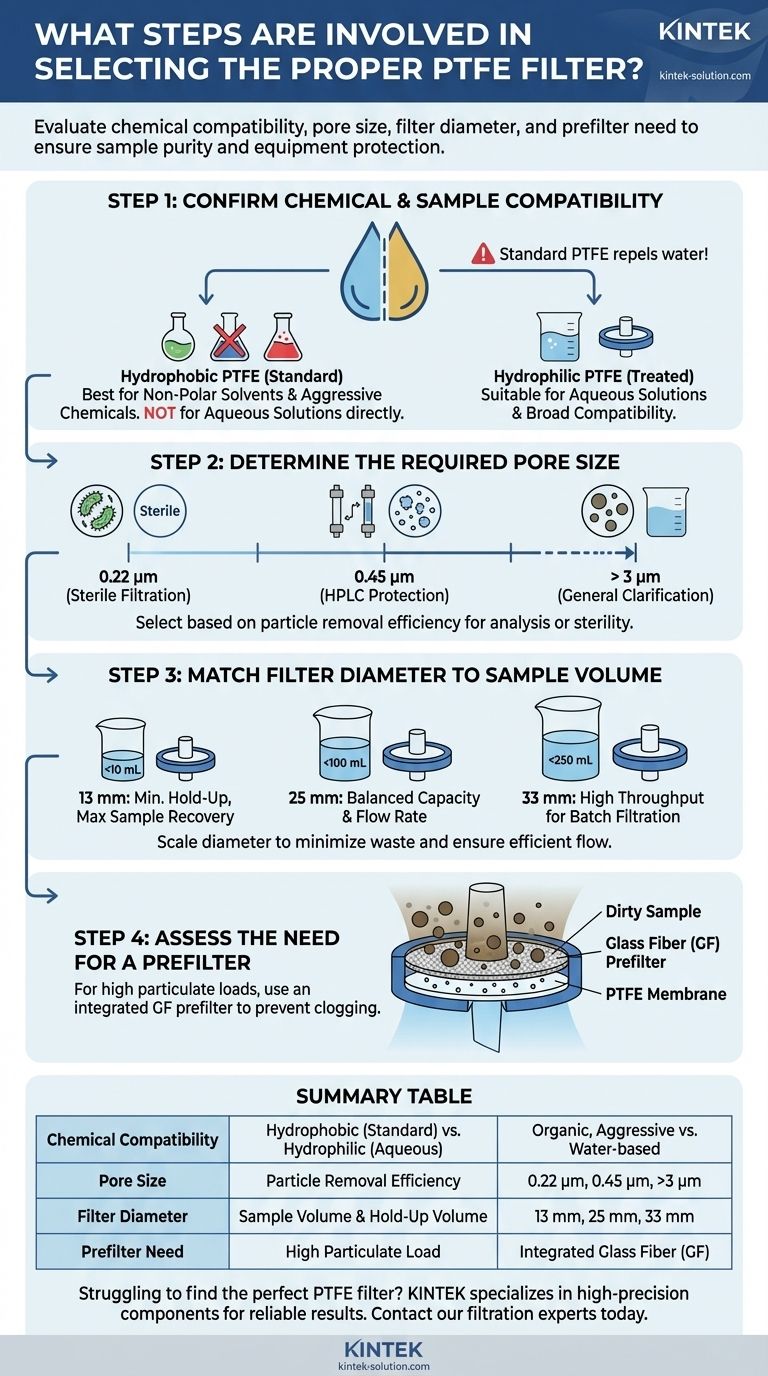

To select the proper PTFE filter, you must evaluate four critical factors: the chemical compatibility of your sample with the hydrophobic PTFE membrane, the required pore size for your application (e.g., clarification vs. sterilization), the appropriate filter diameter for your sample volume, and whether the sample's particulate load necessitates a prefilter.

The core task is not just to filter a liquid, but to prepare a sample for analysis or use with maximum purity and minimal loss. A successful selection balances chemical resistance, particle removal efficiency, and sample volume to ensure your downstream results are reliable and your equipment is protected.

Understanding PTFE's Core Properties

Polytetrafluoroethylene (PTFE) is a go-to membrane material for a specific set of demanding applications. Understanding its fundamental nature is the first step in making an informed choice.

The Defining Trait: Hydrophobicity

PTFE is an inherently hydrophobic (water-repelling) material. This makes it ideal for filtering non-polar, organic solvents and aggressive chemicals that would degrade other membranes.

Exceptional Chemical Resistance

This material exhibits broad resistance to nearly all acids, bases, and aggressive solvents. It is the default choice for chemically harsh filtration tasks where other materials would fail.

The Four-Step Selection Framework

Follow this logical process to ensure you choose the correct filter for your specific task, preventing clogged filters, sample contamination, or equipment damage.

Step 1: Confirm Chemical and Sample Compatibility

While PTFE has excellent chemical resistance, its hydrophobic nature is a critical consideration.

Standard PTFE is not suitable for filtering aqueous solutions directly. Water will not pass through the membrane without extremely high pressure. For aqueous samples, you must either pre-wet the membrane with a solvent like methanol or isopropanol or, more reliably, use a specially treated hydrophilic PTFE filter.

Step 2: Determine the Required Pore Size

The filter's pore size dictates the size of the particles it removes. This is the most critical technical specification for achieving your goal.

A larger pore size (e.g., >3 µm) is used for general clarification and removing large particulates.

A smaller pore size (e.g., <3 µm) is used for fine clarification and analysis. The most common sizes are 0.45 µm for general particulate removal to protect instruments like HPLC columns, and 0.22 µm for sterile filtration.

Step 3: Match Filter Diameter to Sample Volume

The filter's diameter must be scaled to the amount of liquid you are processing to minimize waste and ensure efficient flow.

- For small volumes (<10 mL): A 13 mm diameter filter is typical to minimize sample loss (hold-up volume).

- For medium volumes (<100 mL): A 25 mm diameter filter offers a good balance of capacity and flow rate.

- For larger volumes (<250 mL): A 30 mm or 33 mm filter provides higher throughput for batch filtration.

Step 4: Assess the Need for a Prefilter

If your sample contains a high concentration of particulates, it can quickly clog the fine pores of a standard PTFE membrane.

In these cases, select a syringe filter that includes an integrated prefilter, often made of glass fiber (GF). The GF layer acts as a coarse filter, trapping larger particles and allowing the PTFE membrane to efficiently remove the finer ones, dramatically increasing the filter's capacity.

Understanding the Trade-offs

Selecting a filter is a process of balancing competing factors. Being aware of the potential downsides is crucial for avoiding common errors.

The Risk of Aqueous Sample Failure

The most common mistake is attempting to filter a water-based sample with a standard PTFE filter. This will not work and can lead to frustration, sample loss, and potentially bursting the syringe from excessive pressure. Always confirm your sample type.

Hold-Up Volume and Analyte Loss

Every filter retains a small amount of liquid after filtration, known as the hold-up volume. Using an oversized filter for a small, precious sample can lead to significant analyte loss. Always choose the smallest diameter suitable for your volume.

Extractables and Background Noise

While PTFE is a very "clean" polymer, low-quality filters can contain manufacturing residues called extractables. For sensitive analyses like HPLC or mass spectrometry, always choose filters certified as having low extractables to avoid contaminating your sample and creating background noise in your results.

Making the Right Choice for Your Goal

Use these guidelines to match a filter directly to your primary objective.

- If your primary focus is preparing organic solvents for HPLC: Use a 0.45 µm standard PTFE filter, choosing the diameter based on your sample volume.

- If your primary focus is sterilizing aggressive chemicals or solvents: Use a 0.22 µm standard PTFE filter.

- If your primary focus is filtering a high-particulate "dirty" solvent: Use a PTFE filter with an integrated glass fiber (GF) prefilter.

- If your primary focus is filtering an aqueous solution with broad chemical compatibility: You must use a hydrophilic PTFE filter.

Choosing the correct filter is the first and most critical step toward achieving clean, reliable, and reproducible results in the lab.

Summary Table:

| Selection Factor | Key Consideration | Common Options |

|---|---|---|

| Chemical Compatibility | Hydrophobic (standard) vs. Hydrophilic (aqueous) | Organic solvents, aggressive chemicals, water-based solutions |

| Pore Size | Particle removal efficiency | 0.22 µm (sterile), 0.45 µm (HPLC), >3 µm (clarification) |

| Filter Diameter | Sample volume and hold-up volume | 13 mm (<10 mL), 25 mm (<100 mL), 33 mm (<250 mL) |

| Prefilter Need | High particulate load | Integrated glass fiber (GF) prefilter |

Struggling to find the perfect PTFE filter for your demanding application?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get a filter that delivers maximum purity, protects your sensitive equipment, and provides reliable, reproducible results—whether you need a standard prototype or a high-volume custom order.

Contact our filtration experts today for a consultation tailored to your specific chemical, volume, and particulate challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications