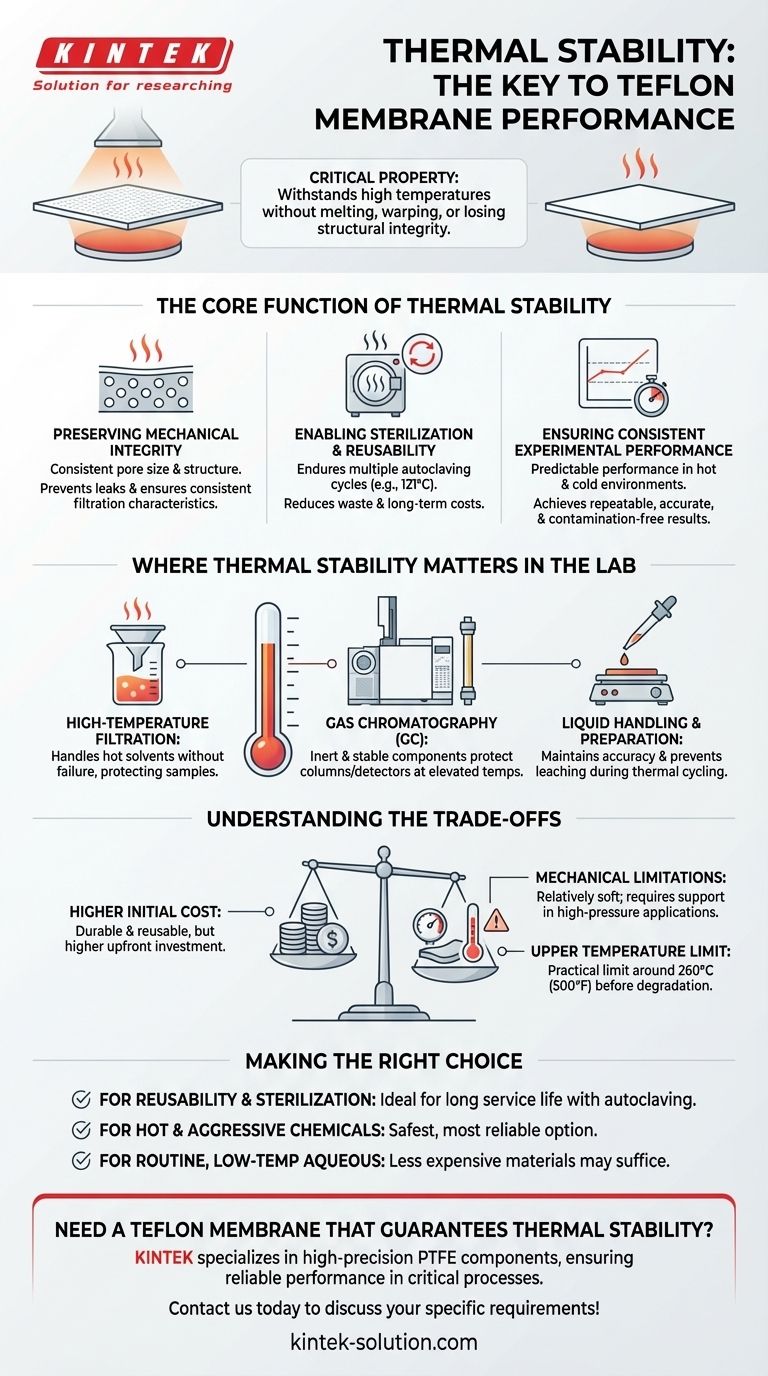

In short, thermal stability is a critical property that allows Teflon membranes to withstand high temperatures without melting, warping, or losing their structural integrity. This ensures they can be used in demanding laboratory processes like autoclaving for sterilization and for filtering hot liquids, all while providing reliable and consistent performance.

The true role of thermal stability in Teflon membranes is not just about heat resistance. It is about ensuring the physical and chemical integrity of the membrane remains constant across a wide range of temperatures, which is fundamental to achieving repeatable, accurate, and contamination-free experimental results.

The Core Function of Thermal Stability

High thermal stability is one of the defining characteristics of Polytetrafluoroethylene (PTFE), the polymer that makes up Teflon membranes. This property has direct and practical consequences for laboratory work.

Preserving Mechanical Integrity

Heat can cause many polymers to soften, deform, or even melt. Teflon’s ability to resist these changes means the membrane's pore size and structure remain consistent, even when exposed to high temperatures.

This structural consistency is essential for preventing leaks and ensuring that the filtration or separation characteristics do not change mid-experiment.

Enabling Sterilization and Reusability

Many laboratory protocols require sterile equipment to prevent contamination. The most common method for sterilization is autoclaving, which uses high-pressure steam at temperatures around 121°C (250°F).

Teflon's thermal stability allows membranes to endure multiple autoclaving cycles without degrading. This makes them reusable, reducing both waste and long-term costs.

Ensuring Consistent Experimental Performance

Reliable science depends on repeatable results. If a membrane's properties changed with temperature, it would introduce a significant variable into an experiment.

Because Teflon membranes perform predictably in both hot and cold environments, they provide the consistency needed for accurate and dependable data, whether in aqueous or non-aqueous solutions.

Where Thermal Stability Matters in the Lab

The ability to handle heat makes Teflon membranes indispensable in several common laboratory applications, ensuring equipment durability and precise control over substances.

High-Temperature Filtration

Many chemical reactions or preparations involve filtering hot solvents, reagents, or solutions. Teflon membranes can handle these tasks without risk of failure, protecting both the sample and the experiment.

Gas Chromatography (GC)

In GC systems, membranes and filters are often used to protect columns and detectors. These components can be exposed to high temperatures, and the material must remain inert and stable to avoid introducing contaminants into the analytical stream.

Liquid Handling and Sample Preparation

Devices that dispense precise volumes of liquids may undergo thermal cycling or be used with heated substances. Teflon components ensure the device remains accurate and does not leach impurities into the sample.

Understanding the Trade-offs

While highly effective, no material is perfect for every situation. Understanding the limitations of Teflon provides a more complete picture for making informed decisions.

Higher Initial Cost

PTFE is a high-performance polymer, and its manufacturing process makes it more expensive than common alternatives like polypropylene, nylon, or cellulose. Its durability and reusability can offset this cost over time, but the initial investment is higher.

Mechanical Limitations

While thermally stable, Teflon is a relatively soft material. It is not as rigid or abrasion-resistant as ceramic or metal filters. In high-pressure applications, it requires proper mechanical support to prevent extrusion or damage.

Upper Temperature Limit

Teflon has an impressive operating range, but it is not infinite. Its practical upper service temperature is generally around 260°C (500°F). Beyond this point, it will begin to degrade, releasing potentially hazardous fumes.

Making the Right Choice for Your Application

Selecting the correct membrane material is crucial for the success of your work. Your specific goal should guide your decision.

- If your primary focus is reusability and sterilization: Teflon is an ideal choice, as its ability to withstand repeated autoclaving cycles ensures a long and reliable service life.

- If your primary focus is working with hot and aggressive chemicals: The unmatched combination of thermal stability and chemical inertness makes Teflon the safest and most reliable option.

- If your primary focus is routine, low-temperature aqueous filtration: A less expensive material like nylon or mixed cellulose ester may be more cost-effective if extreme heat resistance is not required.

Ultimately, understanding the thermal properties of your materials is a key step in ensuring the integrity and accuracy of your scientific work.

Summary Table:

| Application | Role of Thermal Stability | Benefit |

|---|---|---|

| Autoclaving & Sterilization | Withstands high-pressure steam (~121°C) | Enables reusability and prevents contamination |

| High-Temperature Filtration | Maintains pore structure with hot liquids/solvents | Ensures consistent filtration performance |

| Gas Chromatography (GC) | Remains inert and stable at elevated temperatures | Protects columns and detectors from contamination |

Need a Teflon membrane that guarantees thermal stability and chemical inertness for your critical processes?

KINTEK specializes in manufacturing high-precision PTFE components, including custom membranes, seals, and labware. Our expertise ensures your equipment performs reliably under high temperatures, from autoclaving to aggressive chemical filtration, providing the consistency required for accurate, contamination-free results in semiconductor, medical, and laboratory settings.

Contact us today to discuss your specific requirements for prototypes or high-volume orders!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability