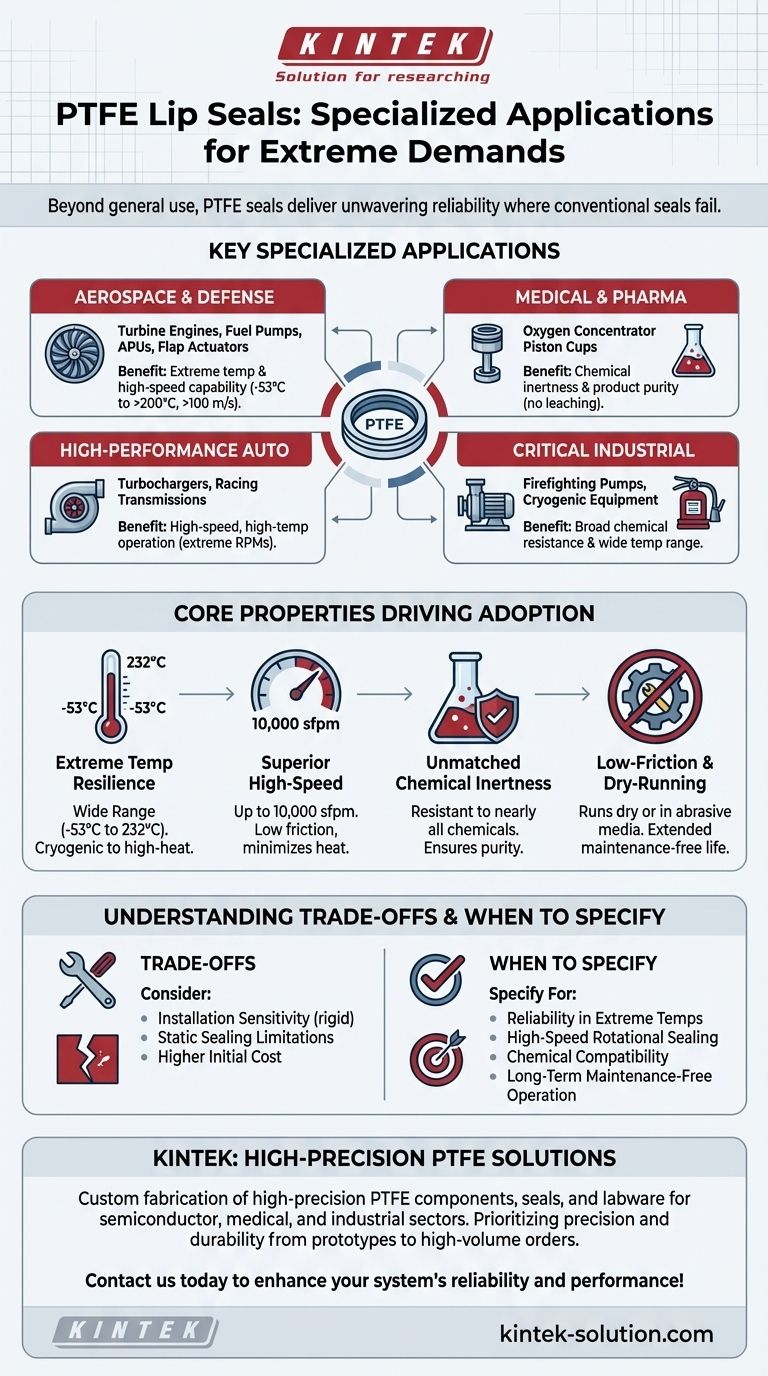

Beyond general industrial use, PTFE lip seals are specified for a range of highly demanding, specialized applications where conventional seals fail. These include critical medical devices like oxygen concentrator piston cup seals, aerospace systems such as jet engine gearboxes and fuel pumps, and high-performance automotive components like turbochargers.

The decision to use a PTFE lip seal is driven by the need for unwavering reliability in extreme operating conditions. They are chosen not as a general-purpose solution, but as an engineered component for applications involving high rotational speeds, aggressive chemicals, or wide temperature ranges that exceed the physical limits of traditional elastomer seals.

Beyond the Factory Floor: Key Specialized Applications

While common in pumps and compressors, the true value of PTFE seals is most evident in applications where performance is non-negotiable.

Aerospace and Defense

In aerospace, reliability is paramount. PTFE seals are used extensively in commercial and military aircraft where they must perform flawlessly across extreme environmental shifts.

Key applications include turbine engines, auxiliary power units (APUs), fuel pumps, and flap actuators. These components demand seals that can handle surface speeds exceeding 100 m/s and temperatures from -53°C at altitude to over 200°C during operation.

Medical and Pharmaceutical

The chemical inertness and purity of PTFE are critical for medical and pharmaceutical equipment. They ensure that no contaminants from the seal material leach into the process.

A prime example is their use as piston cup seals in oxygen concentrators. Here, the seal must provide long-term, maintenance-free operation without degrading from constant contact with concentrated oxygen, a highly oxidative gas.

High-Performance Automotive

Standard automotive applications are demanding, but high-performance and racing sectors push components to their absolute limits.

PTFE seals are essential in turbochargers, high-performance engine crankshafts, and racing transmissions. They withstand the extreme RPMs and high temperatures that would cause conventional rubber seals to melt or wear out prematurely.

Critical Industrial Systems

Certain industrial systems operate under conditions far beyond the norm, requiring specialized sealing solutions.

This includes firefighting pump systems handling aggressive chemical fire retardants and cryogenic equipment operating at extremely low temperatures. In these cases, the broad chemical resistance and wide temperature range of PTFE are indispensable.

The Core Properties Driving Adoption

The selection of PTFE for these critical roles is not arbitrary. It is a direct result of its unique combination of material properties.

Extreme Temperature Resilience

PTFE seals maintain their integrity and performance across a vast temperature range, typically from -53°C to 232°C (-65°F to 450°F). This allows them to function in cryogenic applications and within high-heat environments like jet engines without becoming brittle or degrading.

Superior High-Speed Capability

The material's exceptionally low coefficient of friction allows PTFE seals to handle very high rotational speeds, often up to 10,000 surface feet per minute (sfpm). This minimizes frictional heat buildup and wear, enabling long life in equipment like compressors and turbines.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals and solvents. This property makes it the ideal choice for sealing in chemical processing, food and beverage, and pharmaceutical applications, where it prevents seal degradation and ensures product purity.

Low-Friction and Dry-Running Performance

Unlike elastomers that require lubrication to prevent wear, PTFE seals can run dry or in abrasive media for extended periods. This is a critical advantage in applications like industrial air compressors, where they can achieve over 40,000 maintenance-free hours.

Understanding the Trade-offs

While highly capable, PTFE seals are not a universal replacement for elastomers. Their unique properties come with specific considerations.

Installation Sensitivity

PTFE is a relatively rigid material compared to rubber. This lack of elasticity makes the seals more susceptible to damage during installation if not handled with care and proper tooling.

Static Sealing Limitations

PTFE's strength is in dynamic, rotating applications. While effective, it can be less forgiving than a soft elastomer for purely static sealing, especially if the mating hardware has a poor surface finish.

Design and Material Cost

PTFE lip seals are typically more expensive than standard elastomer seals. They are an engineered component whose value is realized in reduced downtime, extended service life, and the ability to operate where other materials simply cannot.

When to Specify a PTFE Lip Seal

The choice to use a PTFE seal should be based on the specific demands of the application.

- If your primary focus is reliability in extreme temperatures: PTFE is the definitive choice for applications like aerospace engines or cryogenic pumps where elastomers become brittle or degrade.

- If your primary focus is high-speed rotational sealing: For equipment like turbochargers, high-speed spindles, or industrial compressors, PTFE's low friction prevents heat buildup and catastrophic wear.

- If your primary focus is chemical compatibility: In pharmaceutical, food processing, or chemical pumps, PTFE's inertness ensures both product purity and seal longevity against aggressive media.

- If your primary focus is long-term, maintenance-free operation: For critical components like industrial compressors or sealed-for-life gearboxes, the extended lifespan of PTFE justifies the initial investment.

Ultimately, specifying a PTFE lip seal is a decision to prioritize long-term reliability and performance in environments where failure is not an option.

Summary Table:

| Application Area | Key Examples | Primary Benefit of PTFE Seal |

|---|---|---|

| Aerospace & Defense | Turbine engines, APUs, fuel pumps | Extreme temperature resilience, high-speed capability |

| Medical & Pharmaceutical | Oxygen concentrator piston cup seals | Chemical inertness, product purity |

| High-Performance Automotive | Turbochargers, racing transmissions | High-speed, high-temperature operation |

| Critical Industrial Systems | Firefighting pumps, cryogenic equipment | Broad chemical resistance, wide temperature range |

Need a PTFE sealing solution for your demanding application?

At KINTEK, we manufacture high-precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your components perform reliably in extreme conditions, from high-speed rotations to aggressive chemical environments.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision and durability to meet your specific needs.

Contact us today to discuss how our PTFE solutions can enhance your system's reliability and performance!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs