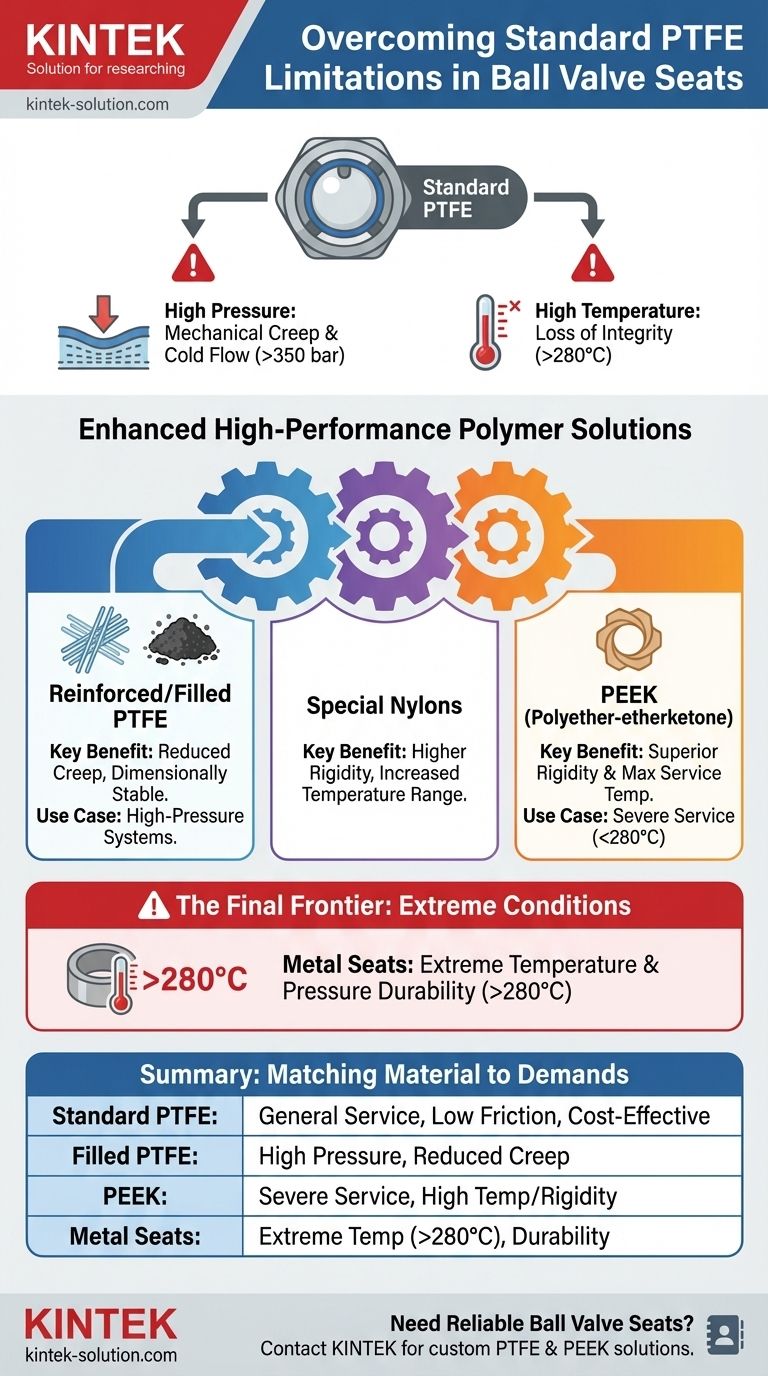

To overcome the limitations of standard PTFE in ball valve seats, engineers use enhanced or alternative high-performance polymers. The primary materials are powder-filled PTFE, special Nylons, and Polyether-etherketone (PEEK), which are selected for their ability to withstand higher pressures and temperatures where standard PTFE would fail.

While standard PTFE is an excellent general-purpose material, it suffers from mechanical creep under high pressure and loses structural integrity at elevated temperatures. The solution is not to abandon polymers, but to select a material specifically engineered for the demands of the application.

The Baseline: Why Standard PTFE is a Starting Point

Before addressing its limitations, it's crucial to understand why Polytetrafluoroethylene (PTFE) is the default choice for so many applications. Its properties create an almost ideal sealing surface under the right conditions.

### Unmatched Low Friction

PTFE possesses the lowest coefficient of friction of any known thermoplastic. This allows for smooth valve operation without lubricants and prevents the "stick-slip" behavior that can cause jerky movements and premature wear.

### Superior Chemical Resistance

PTFE is virtually inert, making it resistant to the harshest chemicals and solvents. This ensures the valve seat will not degrade when exposed to corrosive media.

### Excellent Sealing Capability

The material has sufficient ductility to form a tight, reliable seal against the ball. It also exhibits good stress recovery, allowing it to maintain its shape and sealing function over many cycles.

Uncovering the Limitations of Standard PTFE

The same properties that make PTFE an excellent sealer also create its boundaries. Its relative softness becomes a liability when operational demands increase.

### Weakness Under High Pressure

Standard PTFE seats are not recommended for pressures exceeding 350 bar (approx. 5,000 psi). This limit decreases significantly as the valve size increases; for larger valves (DN32-DN50), the pressure ceiling can drop to as low as 150 bar.

Under high pressure, the material is prone to creep, or cold flow, where it slowly deforms and is extruded from its intended space, leading to seal failure.

### A Firm Temperature Ceiling

PTFE's performance degrades significantly at higher temperatures. For applications consistently running over 280°C (536°F), polymeric seats are no longer a viable option, and metal-seated valves become a necessity.

High-Performance Materials for Demanding Conditions

To solve the problems of pressure and temperature, the industry turns to materials that build upon PTFE's strengths or offer a completely different polymer structure.

### Reinforced PTFE (Powder-Filled PTFE)

This is the most common upgrade. By adding fillers to the virgin PTFE matrix, mechanical properties are drastically improved.

Common fillers include glass fibers, carbon particles, and various mineral powders. These additives act as a reinforcing skeleton within the polymer, dimensionally stabilizing the seat, significantly reducing creep, and enhancing overall mechanical strength.

### PEEK (Polyether-etherketone)

When conditions are too demanding even for filled PTFE, PEEK is often the next step. It is a high-performance semi-crystalline thermoplastic known for its exceptional mechanical properties.

PEEK offers a substantial increase in both rigidity and maximum service temperature compared to any PTFE variant, making it a premier choice for severe service applications.

### Special Nylons

Certain formulations of Nylon are also used as an alternative to PTFE. Like PEEK, they are selected to provide higher rigidity and an increased service temperature range.

### The Final Frontier: Metal Seats

It is critical to recognize the absolute limit of polymers. For any service environment exceeding 280°C, the only reliable solution is a metal-seated ball valve, which sacrifices the soft-seat's bubble-tight seal for extreme temperature and pressure durability.

Understanding the Trade-offs

Choosing a high-performance material is not without consequences. Moving away from standard PTFE involves balancing performance gains against other factors.

### Performance vs. Cost

There is a direct correlation between performance and price. Standard PTFE is the most cost-effective option. Filled PTFE is more expensive, and PEEK represents a significant cost increase, reserved for applications where its performance is non-negotiable.

### Altered Sealing Characteristics

Adding fillers to PTFE can slightly increase its coefficient of friction and may alter its broad chemical resistance profile. While the seal is mechanically stronger, some of the unique benefits of pure, virgin PTFE are moderately compromised.

### Rigidity vs. Sealing

Extremely rigid materials like PEEK or metal provide excellent resistance to pressure and temperature but are less forgiving than soft-seated materials. They may require higher operating torque and are more susceptible to leakage if solids are present in the media.

Selecting the Right Seat Material for Your Application

The optimal choice is always the one that meets the application's demands without over-engineering the solution.

- If your primary focus is general service with moderate pressure and temperature: Standard PTFE remains the ideal choice for its excellent sealing, low friction, and cost-effectiveness.

- If your primary focus is preventing material creep in high-pressure systems: Powder-filled PTFE provides the necessary dimensional stability and mechanical strength.

- If your primary focus is maximizing temperature resistance and rigidity below 280°C: PEEK is the superior polymer choice for the most demanding service conditions.

- If your application consistently operates above 280°C: Metal-seated valves are the only safe and reliable option.

Matching the seat material to the specific operational demands of your system is the definitive step toward ensuring valve reliability and longevity.

Summary Table:

| Material | Key Benefit | Typical Use Case |

|---|---|---|

| Standard PTFE | Excellent chemical resistance, low friction | General service, moderate pressure/temperature |

| Filled/Reinforced PTFE | Reduced creep, higher mechanical strength | High-pressure systems |

| PEEK | High rigidity, superior temperature resistance | Severe service conditions (<280°C) |

| Metal Seats | Extreme temperature and pressure durability | Applications consistently >280°C |

Need a Reliable Ball Valve Seat for Demanding Conditions?

Standard PTFE not holding up in your high-pressure or high-temperature application? KINTEK specializes in manufacturing precision PTFE components, including custom ball valve seats. We work with semiconductor, medical, laboratory, and industrial clients to provide solutions that overcome material limitations.

We can help you select or fabricate the right seat material—from filled PTFE to PEEK—for your specific operational demands, ensuring valve reliability and longevity.

Contact KINTEB today to discuss your application and get a custom solution quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications