At their core, PTFE V-Rings are machined from a single, high-purity material: Polytetrafluoroethylene (PTFE). This specific material choice is fundamental to their performance, providing a unique set of properties that make them suitable for demanding sealing applications where common elastomers would quickly fail.

The selection of pure PTFE is not arbitrary; it's a deliberate engineering choice to achieve an exceptional combination of chemical inertness, low friction, and broad temperature resistance required for challenging dynamic sealing environments.

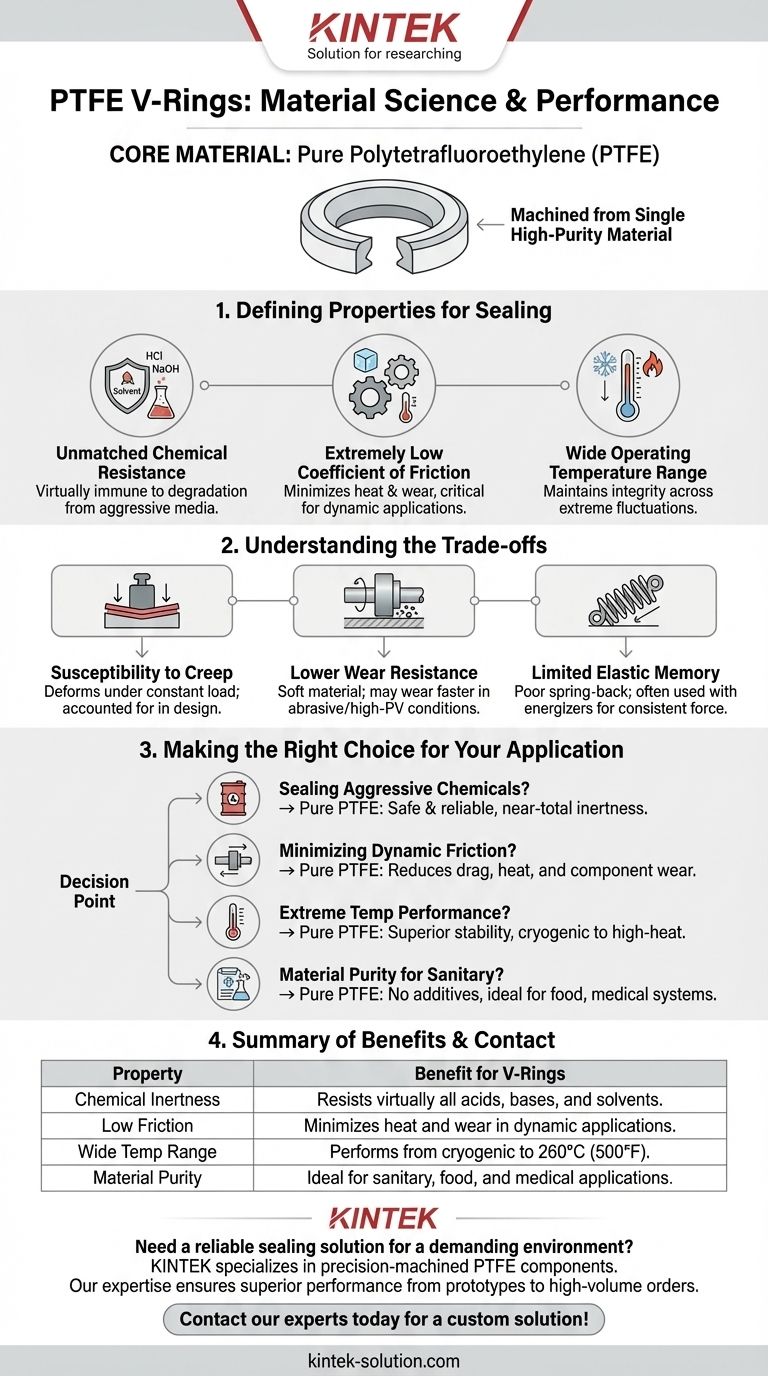

The Defining Properties of PTFE for Sealing

To understand why pure PTFE is used for V-Rings, we must look at the material's intrinsic characteristics. These properties directly translate into the seal's performance in an assembly.

Unmatched Chemical Resistance

PTFE is one of the most chemically inert polymers known. It is virtually immune to degradation from acids, bases, solvents, and other aggressive media.

This makes PTFE V-Rings the default choice for applications in chemical processing, pharmaceuticals, and any environment involving corrosive fluids.

Extremely Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice.

In dynamic applications, like a reciprocating shaft, this "slipperiness" is critical. It minimizes heat generation, reduces wear on both the seal and the hardware, and lowers the energy required to operate the equipment.

Wide Operating Temperature Range

Pure PTFE maintains its integrity and sealing properties across an exceptionally wide temperature spectrum, typically from cryogenic levels up to approximately 260°C (500°F).

This thermal stability allows PTFE V-Rings to be used in systems that experience significant temperature fluctuations without the material becoming brittle or degrading.

Understanding the Trade-offs of Pure PTFE

No material is perfect for every scenario. An objective assessment requires acknowledging the inherent limitations of using pure, unfilled PTFE.

Susceptibility to Creep

Under a constant compressive load, pure PTFE can be susceptible to "creep" or cold flow. This means the material can slowly deform over time.

This characteristic must be accounted for during the design of the seal gland and energizer to ensure a consistent sealing force is maintained throughout the life of the component.

Lower Wear Resistance

While its low friction reduces wear, pure PTFE is a relatively soft material. In applications with abrasive media or high-pressure-velocity (PV) conditions, it may wear more quickly than harder materials or filled PTFE compounds.

Limited Elastic Memory

Unlike rubber or other elastomers, PTFE has poor elastic memory. It does not readily spring back to its original shape after being compressed.

This is why V-Ring sets are often used with a spring or elastomer energizer. The energizer provides the constant outward force needed to keep the PTFE sealing lips engaged with the hardware.

Making the Right Choice for Your Application

Selecting a pure PTFE V-Ring is a decision driven by the specific demands of your operating environment.

- If your primary focus is sealing against aggressive chemicals: Pure PTFE is one of the safest and most reliable choices available due to its near-total chemical inertness.

- If your primary focus is minimizing friction in a dynamic system: The exceptionally low coefficient of friction of PTFE will reduce drag, heat, and component wear.

- If your primary focus is performance across extreme temperatures: PTFE's stability in both cryogenic and high-heat conditions makes it a superior choice over most elastomers.

- If your primary focus is material purity for sanitary applications: Virgin PTFE contains no additives or plasticizers that could leach out, making it ideal for food, beverage, and medical systems.

Ultimately, choosing a pure PTFE V-Ring is a strategic decision for achieving reliable sealing in the most demanding operational environments.

Summary Table:

| Property | Benefit for V-Rings |

|---|---|

| Chemical Inertness | Resists virtually all acids, bases, and solvents. |

| Low Friction | Minimizes heat and wear in dynamic applications. |

| Wide Temp Range | Performs from cryogenic to 260°C (500°F). |

| Material Purity | Ideal for sanitary, food, and medical applications. |

Need a reliable sealing solution for a demanding environment?

At KINTEK, we specialize in precision-machined PTFE components, including custom V-Rings. Our expertise in PTFE fabrication ensures you get a seal that delivers superior performance in semiconductor, medical, laboratory, and industrial applications—from prototypes to high-volume orders.

Contact our experts today to discuss your specific requirements and get a solution engineered for reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability