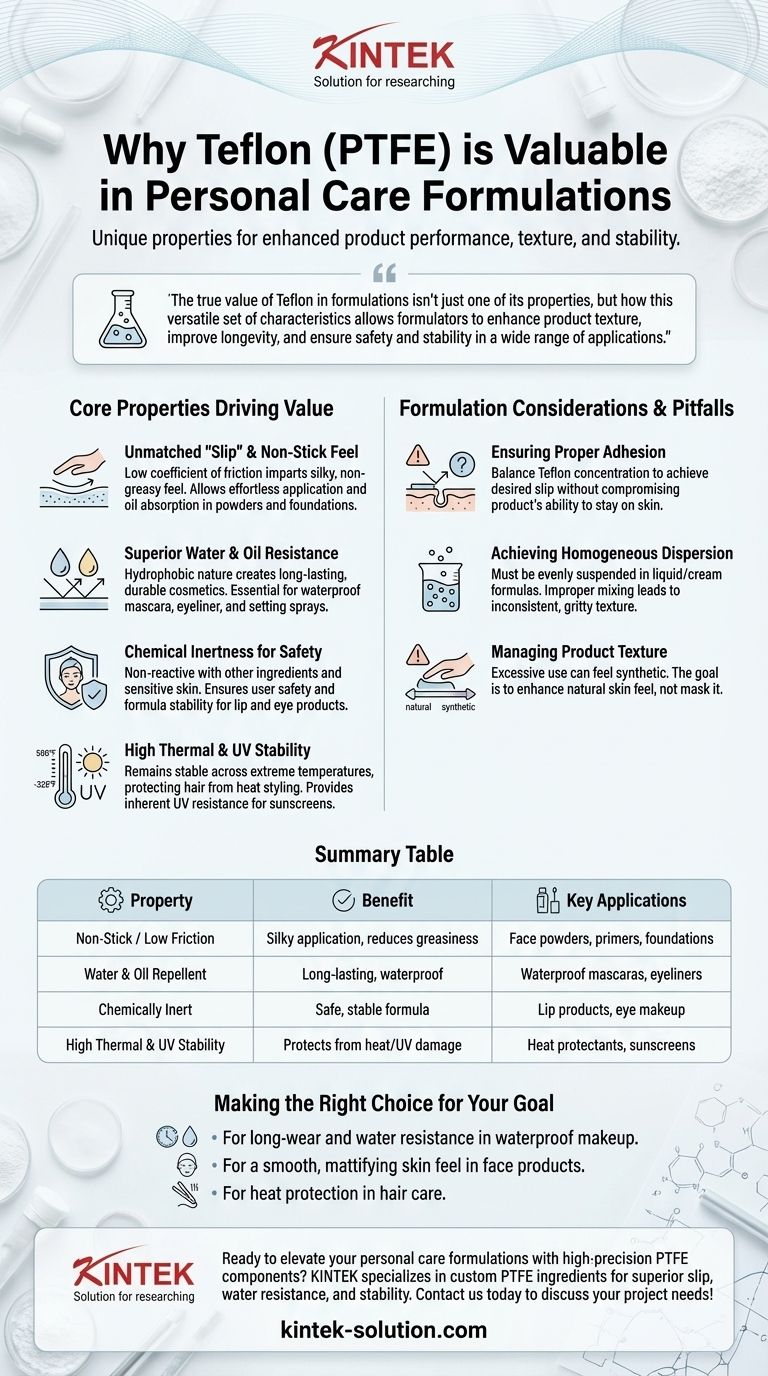

At its core, Teflon—known chemically as Polytetrafluoroethylene (PTFE)—is a valuable ingredient in personal care because its unique combination of physical properties directly solves common product performance challenges. Its value comes from being simultaneously non-stick, water-repellent, chemically inert, and highly resistant to heat and UV radiation, improving everything from the feel of a powder to the durability of waterproof makeup.

The true value of Teflon in formulations isn't just one of its properties, but how this versatile set of characteristics allows formulators to enhance product texture, improve longevity, and ensure safety and stability in a wide range of applications.

The Core Properties Driving Teflon's Value

To understand its role, we must first break down the specific physical traits that make Teflon so effective in cosmetic and personal care science. Each property addresses a distinct need in product formulation.

### Unmatched "Slip" and Non-Stick Feel

Teflon is renowned for its low coefficient of friction and anti-adhesive qualities. In simple terms, it creates an incredibly smooth, slippery surface.

When milled into a fine powder and added to products like dusting powders or foundations, it imparts a silky, non-greasy feel. This allows products to glide onto the skin effortlessly and helps absorb excess oil or sweat without caking.

### Superior Water and Oil Resistance

Teflon is fundamentally hydrophobic, meaning it repels water. This is a critical feature for creating long-lasting, durable cosmetics.

This property is the key to waterproof mascaras, eyeliners, and setting sprays that resist smudging or running when exposed to moisture, humidity, or sweat.

### Chemical Inertness for Safety and Stability

One of Teflon's most important features is that it is non-reactive and highly resistant to chemical degradation.

This chemical inertness makes it exceptionally safe for use on sensitive areas like the eyes and lips. It will not react with the skin or with other ingredients in the formula, ensuring both user safety and the stability of the final product.

### High Thermal and UV Stability

Teflon remains stable across an exceptionally wide temperature range, from as low as -328°F to as high as 500°F.

This thermal stability is crucial for hair care products designed to be used with hot styling tools like blow dryers or flat irons, as it protects the hair without breaking down. Furthermore, its inherent UV resistance allows it to be used in sunscreens and skin protectants to help shield the skin from UV ray penetration.

Common Pitfalls and Formulation Considerations

While Teflon's properties are highly beneficial, its very nature presents unique challenges for formulators. Understanding these is key to leveraging its strengths effectively.

### Ensuring Proper Adhesion

The primary benefit of Teflon is its non-stick nature. However, in a product like foundation or lipstick, the formula must still adhere to the skin.

Formulators must carefully balance the concentration of Teflon to achieve the desired slip and longevity without compromising the product's ability to stay in place.

### Achieving Homogeneous Dispersion

As an inert, solid powder, Teflon must be evenly suspended throughout a liquid or cream-based formula to deliver its benefits consistently.

Improper mixing or a lack of appropriate suspension agents can lead to an inconsistent texture or a gritty feel, completely negating the desired silky effect.

### Managing Product Texture

While Teflon creates a desirable slip, using too much can result in a finish that feels overly synthetic or artificial.

The goal is to enhance the natural feel of the skin or hair, not to mask it. Finding the correct percentage is a critical part of the formulation art.

Making the Right Choice for Your Goal

Ultimately, incorporating Teflon is a strategic decision based on the desired performance outcome of the final product.

- If your primary focus is long-wear and water resistance: Leverage its hydrophobic properties for waterproof makeup like mascara and setting sprays.

- If your primary focus is a smooth, mattifying skin feel: Utilize its low coefficient of friction in face powders, primers, and foundations for a silky, non-greasy finish.

- If your primary focus is heat protection for hair: Capitalize on its exceptional thermal stability to create effective heat protectant sprays and serums.

By understanding its core properties and formulation nuances, you can use this ingredient to solve specific performance problems with precision and efficacy.

Summary Table:

| Property | Benefit in Personal Care | Key Applications |

|---|---|---|

| Non-Stick / Low Friction | Silky, smooth application; reduces greasiness | Face powders, primers, foundations |

| Water & Oil Repellent | Long-lasting, waterproof wear; resists smudging | Waterproof mascaras, eyeliners, setting sprays |

| Chemically Inert | Safe for sensitive skin; formula stability | Lip products, eye makeup, all skin types |

| High Thermal & UV Stability | Protects against heat damage; UV resistance | Heat protectant sprays, sunscreens, styling products |

Ready to elevate your personal care formulations with high-precision PTFE components?

At KINTEK, we specialize in manufacturing custom PTFE (Teflon) ingredients—including fine powders, seals, and labware—that deliver the exact properties your products need: superior slip, lasting water resistance, and unmatched stability. Whether you're developing a new waterproof mascara, a silky-smooth foundation, or a heat-protective hair serum, our materials ensure consistent quality, safety, and performance.

We partner with brands in the cosmetic, medical, and laboratory industries to provide tailored solutions from prototype to high-volume production. Let us help you solve formulation challenges and create standout products.

Contact us today to discuss your project needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers