In short, PTFE is exceptionally suitable for piping and tubing systems due to its unique combination of properties that solve critical industrial challenges. Its extreme chemical inertness prevents corrosion from acids and alkalis, its high-temperature tolerance maintains integrity during thermal cycling, and its low-friction, non-stick surface ensures both smooth flow and protection from mechanical wear.

The core reason for PTFE's value in piping is not just one of its properties, but how they work together. This synergy creates a highly durable, safe, and low-maintenance barrier that protects both the piping system from its contents and the contents from contamination.

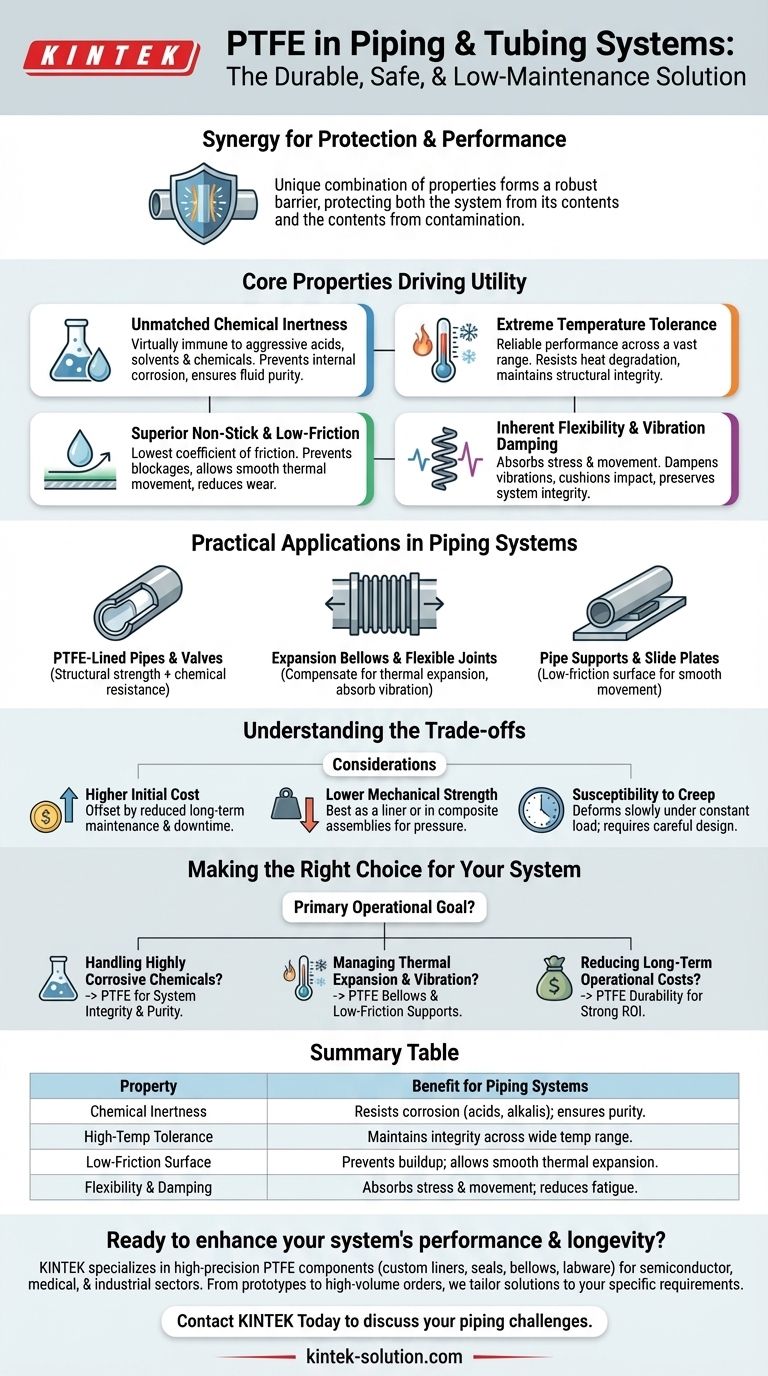

The Core Properties Driving PTFE's Utility

To understand why PTFE is so prevalent, we must first examine its fundamental characteristics. Each property directly addresses a common failure point in industrial piping.

Unmatched Chemical Inertness

PTFE is one of the most non-reactive substances known. It is virtually immune to attack from aggressive acids, solvents, and chemicals.

This inertness is critical for preventing internal corrosion of pipes and valves, which is a primary cause of leaks, system failure, and costly downtime. It also ensures the purity of the fluid being transported, which is vital in industries like pharmaceuticals and food processing.

Extreme Temperature Tolerance

PTFE components perform reliably across a vast temperature range. This stability is essential for systems that handle hot fluids or are exposed to fluctuating environmental conditions.

By resisting degradation from heat, PTFE maintains its structural and chemical integrity, ensuring consistent performance and preventing material failure.

Superior Non-Stick and Low-Friction Surface

PTFE has one of the lowest coefficients of friction of any solid material, creating a slick, non-stick surface.

This property prevents material from sticking to the inside of pipes, which can cause blockages and contaminate processes. On external supports, this low-friction surface allows pipes to glide smoothly during thermal expansion and contraction, preventing abrasive wear and tear.

Inherent Flexibility and Vibration Damping

While strong, PTFE also possesses a degree of flexibility. This allows it to be used in components designed to absorb movement and stress.

It effectively dampens vibrations and can cushion the impact between pipes and their supports. This preserves the structural integrity of the entire system and reduces fatigue on critical connection points.

Practical Applications in Piping Systems

These core properties translate directly into tangible components that solve specific problems within a piping network.

PTFE-Lined Pipes and Valves

The most common application is using PTFE as a liner inside a metal pipe. This provides the structural strength of steel or another alloy with the complete chemical resistance of PTFE on all wetted surfaces.

Expansion Bellows and Flexible Joints

Flexible components made from PTFE are installed to compensate for thermal expansion, absorb vibrations, and allow for minor misalignment. This drastically reduces mechanical stress on the rigid sections of the piping system.

Pipe Supports and Slide Plates

PTFE liners or plates are integrated into pipe support systems. This creates a low-friction surface that allows pipes to move freely as they expand and contract, preventing the abrasive damage that occurs when metal pipes rub against metal supports.

Understanding the Trade-offs

No material is perfect for every situation. A clear-eyed assessment requires acknowledging PTFE's limitations.

Higher Initial Cost

Components made with or lined with PTFE typically have a higher upfront material cost than standard carbon steel or some other polymers.

However, this initial investment is often offset by significantly reduced maintenance costs, less frequent replacement, and the prevention of expensive, unplanned downtime over the system's lifespan.

Lower Mechanical Strength

PTFE is not a high-strength material on its own and is not typically used for high-pressure, structural applications without reinforcement.

This is why it is most effective as a liner within a stronger host pipe or as a component in a composite assembly, where it provides the chemical and thermal barrier while another material provides the pressure containment.

Susceptibility to Creep

Under a constant mechanical load, especially at elevated temperatures, PTFE can slowly deform over time in a process known as "creep."

Engineers must account for this characteristic when designing flanges, gaskets, and other sealing components to ensure they maintain their sealing force throughout their service life.

Making the Right Choice for Your System

Selecting the right materials is about aligning their properties with your primary operational goals.

- If your primary focus is handling highly corrosive chemicals: PTFE's chemical inertness makes it the definitive choice for liners and components to ensure system integrity and prevent contamination.

- If your primary focus is managing thermal expansion and vibration: PTFE expansion bellows and low-friction pipe supports are essential for absorbing stress and preventing mechanical failure.

- If your primary focus is reducing long-term operational costs: The durability and low-maintenance nature of PTFE components provide a strong return on investment by minimizing downtime and repairs.

Ultimately, integrating PTFE into a piping system is a strategic decision to enhance durability, safety, and efficiency in demanding operational environments.

Summary Table:

| Property | Benefit for Piping Systems |

|---|---|

| Chemical Inertness | Resists corrosion from acids, solvents, and alkalis; ensures fluid purity. |

| High-Temperature Tolerance | Maintains integrity and performance across a wide temperature range. |

| Low-Friction Surface | Prevents material buildup and blockages; allows smooth thermal expansion. |

| Flexibility & Vibration Damping | Absorbs stress and movement, reducing mechanical fatigue. |

Ready to enhance your piping system's performance and longevity?

KINTEK specializes in manufacturing high-precision PTFE components—including custom liners, seals, bellows, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get a solution tailored to your specific chemical, thermal, and mechanical requirements.

Contact KINTEK today to discuss how our PTFE components can solve your toughest piping challenges and deliver a strong return on investment through enhanced durability and reduced maintenance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Microwave Digestion Vessels for Demanding Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs