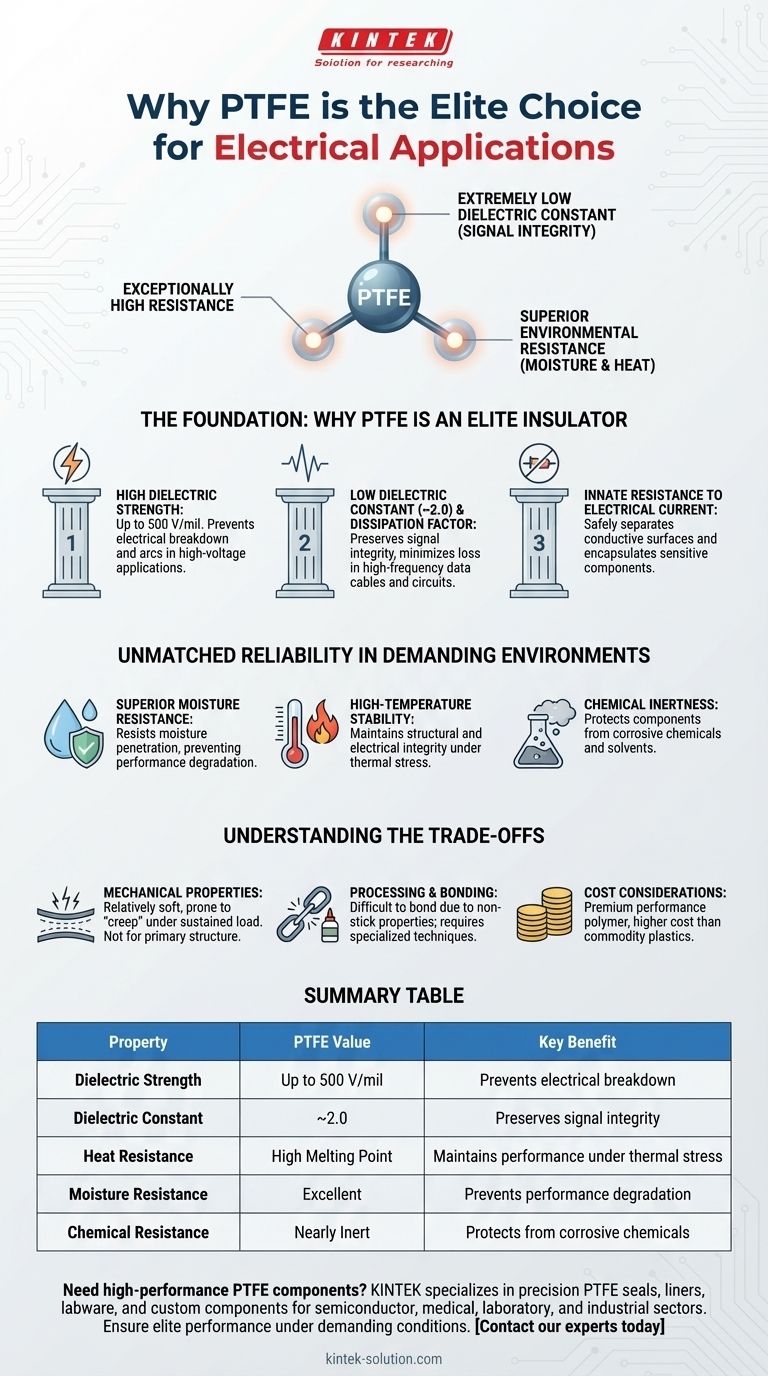

At its core, Polytetrafluoroethylene (PTFE) is suitable for electrical applications because it combines three critical properties: exceptionally high electrical resistance, an extremely low dielectric constant that preserves signal integrity, and superior resistance to environmental factors like moisture and heat. This unique combination ensures its insulating qualities do not degrade over time, making it far more reliable than common plastics like PVC or nylon.

While many materials can insulate electricity, PTFE's primary value is its ability to maintain elite electrical performance under conditions that would cause other insulators to fail. Its molecular structure provides a stable foundation for reliability in the most demanding electronic systems.

The Foundation: Why PTFE is an Elite Insulator

PTFE's suitability begins at the molecular level. Its highly symmetric macromolecular structure is the source of its exceptional electrical properties, setting it apart from other polymers.

Exceptionally High Dielectric Strength

Dielectric strength is a material's ability to withstand a strong electric field without breaking down and conducting electricity.

PTFE is one of the best insulators known, capable of insulating up to 500 volts per mil (a mil is one-thousandth of an inch). This makes it ideal for preventing shorts and arcs in high-voltage applications.

Low Dielectric Constant and Dissipation Factor

The dielectric constant measures a material's ability to store electrical energy. A low value is critical for high-frequency applications, as it minimizes signal loss and interference.

PTFE has a very low dielectric constant of 2.0. This property ensures that the integrity of signals traveling through data cables or across circuit boards is preserved, which is essential for reliable performance.

Innate Resistance to Electrical Current

Fundamentally, an insulator's job is to block the flow of electrical current.

PTFE's high resistance to electrical currents makes it a safe and reliable choice for separating conductive surfaces, such as in capacitors, or for encapsulating sensitive electronic components.

Unmatched Reliability in Demanding Environments

An insulator is only as good as its ability to perform in the real world. PTFE's physical resilience ensures its electrical properties remain stable over the long term, even when exposed to harsh conditions.

Superior Moisture Resistance

Moisture is a primary cause of electrical insulation failure in many plastics.

PTFE resists moisture penetration far better than most polymers. This prevents a gradual decline in insulating performance, a common issue for materials like nylon in humid environments.

High-Temperature Stability

Electrical components often generate significant heat, which can degrade or melt standard insulators.

PTFE has a high melting temperature and maintains its structural and electrical integrity under thermal stress, ensuring consistent performance in high-temperature operating conditions.

Chemical Inertness

In many industrial settings, components may be exposed to corrosive chemicals or solvents.

PTFE is almost completely chemically inert. This property protects the insulated component, guaranteeing that its electrical performance is not compromised by chemical attack.

Understanding the Trade-offs

No material is perfect for every situation. While PTFE's electrical and chemical properties are world-class, it is essential to understand its limitations to make an informed decision.

Mechanical Properties

PTFE is a relatively soft material and can be prone to "creep," or slow deformation under a sustained load. It is not intended for use as a primary structural component.

Processing and Bonding

The same non-stick properties that make PTFE famous also make it very difficult to bond with adhesives. Joining PTFE components often requires specialized techniques like chemical etching.

Cost Considerations

PTFE is a premium performance polymer. It is significantly more expensive than commodity plastics like PVC or polyethylene, making it best suited for applications where its specific advantages are a necessity.

Making the Right Choice for Your Application

Selecting the right insulator requires matching the material's strengths to your primary engineering goal.

- If your primary focus is signal integrity (e.g., high-frequency data cables): PTFE's low dielectric constant is its most critical advantage, preventing signal loss and distortion.

- If your primary focus is high-voltage insulation (e.g., standoff insulators): PTFE's extremely high dielectric strength provides the safety margin you need to prevent electrical breakdown.

- If your primary focus is reliability in a harsh environment: PTFE's resistance to moisture, heat, and chemicals ensures it will not degrade and fail over time.

- If your primary focus is general-purpose, low-cost insulation: A less expensive material like PVC may be sufficient for applications not exposed to extreme conditions.

By understanding these distinct properties, you can confidently specify PTFE where electrical performance and long-term reliability are paramount.

Summary Table:

| Property | PTFE Value | Key Benefit |

|---|---|---|

| Dielectric Strength | Up to 500 V/mil | Prevents electrical breakdown in high-voltage applications |

| Dielectric Constant | ~2.0 | Preserves signal integrity in high-frequency circuits |

| Heat Resistance | High melting point | Maintains performance under thermal stress |

| Moisture Resistance | Excellent | Prevents performance degradation in humid environments |

| Chemical Resistance | Nearly inert | Protects components from corrosive chemicals |

Need high-performance PTFE components for your critical application?

KINTEK specializes in manufacturing precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your electrical insulation maintains elite performance under demanding conditions.

Contact our experts today to discuss your custom fabrication needs, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support