The remarkable durability of Polytetrafluoroethylene (PTFE) is not an accident of design, but a direct result of its fundamental chemistry. Its exceptional resistance to UV radiation and weathering stems from the immense strength and stability of its carbon-fluorine bonds. This molecular structure creates an inert, non-reactive surface that effectively shrugs off the energy from UV rays and resists chemical degradation from environmental exposure.

The core reason for PTFE's resilience is that its resistance is not an additive or a coating; it is an inherent property of its chemical makeup. The powerful bond between its carbon and fluorine atoms forms a permanent molecular shield that UV radiation and corrosive elements cannot easily penetrate or break down.

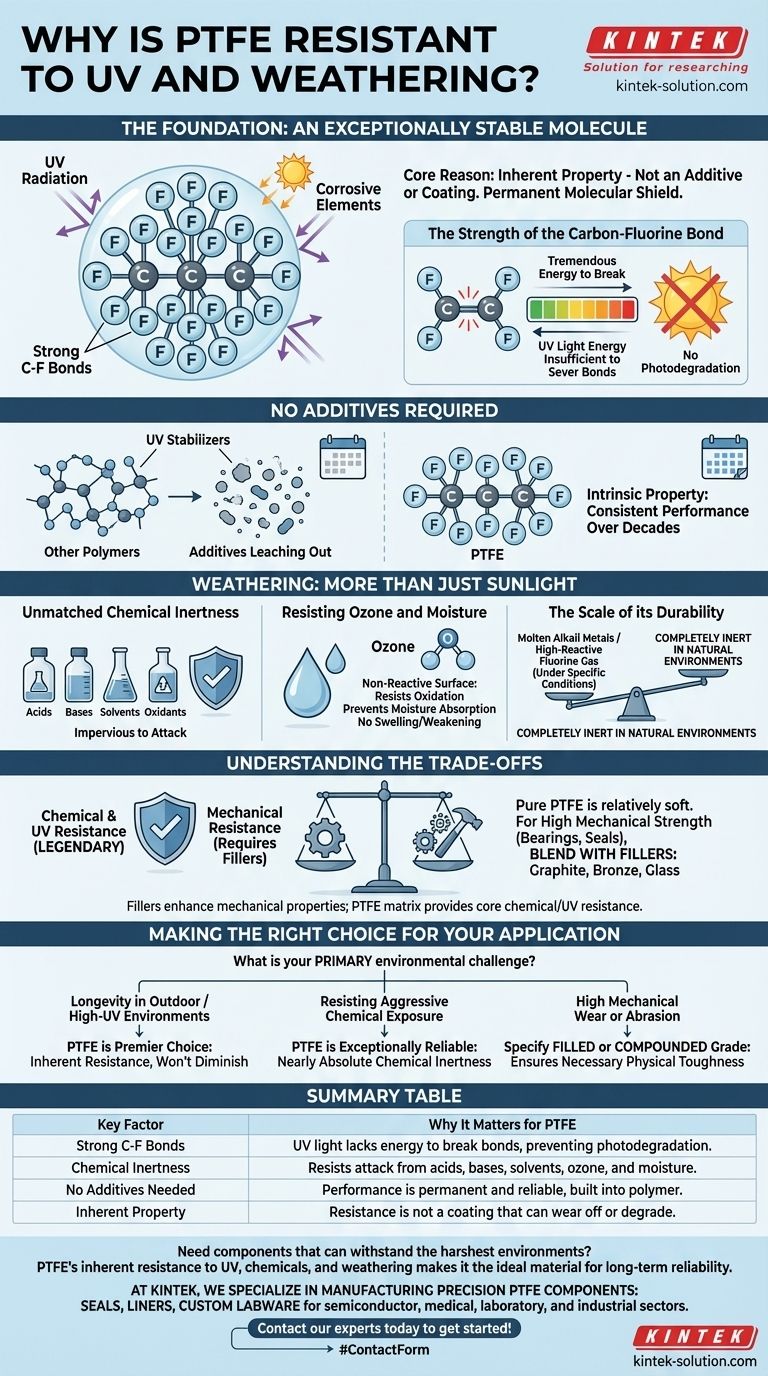

The Foundation: An Exceptionally Stable Molecule

The properties that make PTFE so resistant to environmental factors are rooted in its unique molecular structure. This isn't a complex feature but rather a simple, incredibly robust chemical bond.

The Strength of the Carbon-Fluorine Bond

The bond between carbon (C) and fluorine (F) atoms is one of the strongest single bonds in organic chemistry. PTFE is essentially a long chain of carbon atoms completely sheathed by fluorine atoms.

This tight, strong bond requires a tremendous amount of energy to break. The energy delivered by UV radiation from sunlight is simply insufficient to sever these bonds and cause the material to degrade, a process known as photodegradation.

No Additives Required

Many other polymers require special UV-stabilizing additives to survive outdoors. These additives can break down over time or leach out of the material, eventually leaving it vulnerable.

Because PTFE's UV resistance is an intrinsic property of its molecular structure, it needs no such additives. Its performance remains consistent and reliable over decades of exposure.

Weathering: More Than Just Sunlight

True weather resistance involves more than just surviving UV exposure. It requires resilience against a wide range of chemical and environmental attacks, an area where PTFE's inert nature excels.

Unmatched Chemical Inertness

The same stable C-F bond that resists UV radiation also makes PTFE nearly impervious to chemical attack. It is unaffected by a vast range of corrosive agents, including concentrated acids, bases, solvents, and powerful oxidants.

Resisting Ozone and Moisture

Weathering also includes constant exposure to atmospheric elements like ozone and moisture, which can degrade lesser materials. PTFE's non-reactive surface resists oxidation from ozone and does not absorb water, preventing swelling, weakening, or other forms of moisture-related damage.

The Scale of its Durability

To put its resilience in perspective, very few substances can attack PTFE. Only extreme materials like molten alkali metals and highly reactive fluorine gas under specific conditions can compromise its structure. For all practical purposes in natural environments, it is completely inert.

Understanding the Trade-offs

While PTFE's chemical and UV resistance is legendary, it's crucial to distinguish this from its mechanical properties. Confusing these can lead to material misapplication.

Chemical vs. Mechanical Resistance

PTFE's incredible stability against chemical and UV attack does not directly translate to high resistance against physical abrasion or wear. In its pure form, PTFE is a relatively soft material.

The Role of Fillers

For applications requiring high mechanical strength, such as bearings or seals, PTFE is often blended with fillers like graphite, bronze, or glass. These "compounds" significantly improve wear resistance and rigidity.

It is important to understand that these fillers enhance mechanical properties, while the PTFE matrix itself continues to provide the core chemical, UV, and weather resistance.

Making the Right Choice for Your Application

When evaluating PTFE, your decision should hinge on the primary environmental challenge your component will face.

- If your primary focus is longevity in outdoor or high-UV environments: PTFE is a premier choice because its resistance is inherent to its molecular structure and won't diminish over time.

- If your primary focus is resisting aggressive chemical exposure: PTFE's chemical inertness is nearly absolute, making it exceptionally reliable against almost all acids, solvents, and corrosive agents.

- If your primary focus is high mechanical wear or abrasion: You must specify a filled or compounded grade of PTFE to ensure the material has the necessary physical toughness for the task.

Ultimately, understanding that PTFE's strength lies in its fundamental chemical stability allows you to deploy it with confidence in the most demanding environments.

Summary Table:

| Key Factor | Why It Matters for PTFE |

|---|---|

| Strong C-F Bonds | UV light lacks the energy to break these bonds, preventing photodegradation. |

| Chemical Inertness | Resists attack from acids, bases, solvents, ozone, and moisture. |

| No Additives Needed | Performance is permanent and reliable, as resistance is built into the polymer. |

| Inherent Property | The resistance is not a coating that can wear off or degrade over time. |

Need components that can withstand the harshest environments?

PTFE's inherent resistance to UV, chemicals, and weathering makes it the ideal material for long-term reliability in demanding applications. At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We offer custom fabrication from prototypes to high-volume orders, ensuring your parts are built to last. Let's discuss how our PTFE solutions can solve your specific challenges.

Contact our experts today to get started!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials