The durability of PTFE gaskets in ball valve applications stems from a powerful combination of chemical inertness, a wide operational temperature range, and inherent resistance to degradation. These properties ensure the material maintains its sealing integrity over long periods across a vast array of demanding industrial environments.

PTFE is often the default choice for general-purpose ball valve seals because it is chemically non-reactive and thermally resilient. However, its effectiveness is defined by its physical limitations, particularly its susceptibility to deformation under sustained pressure and its sensitivity to high radiation.

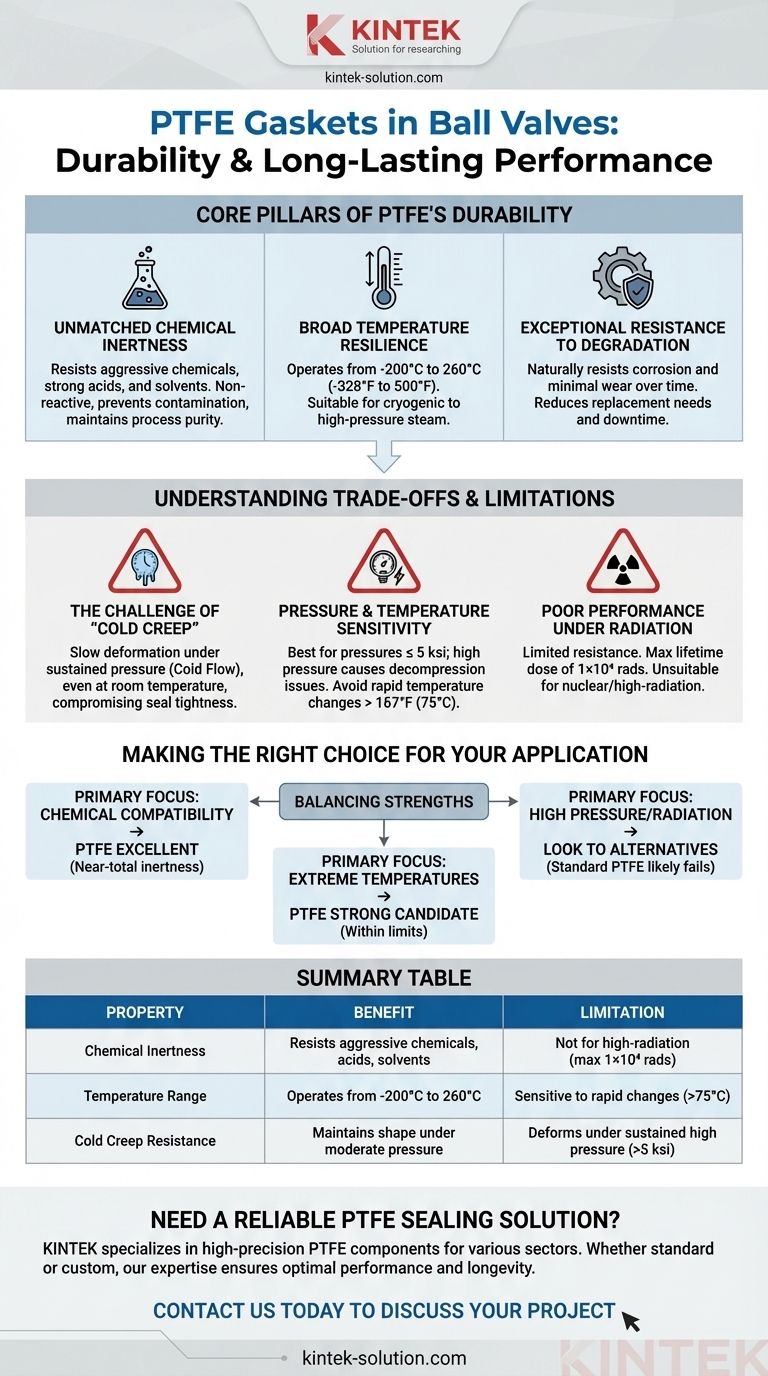

The Core Pillars of PTFE's Durability

Polytetrafluoroethylene (PTFE) possesses a unique molecular structure that gives it three primary advantages for creating long-lasting seals in ball valves.

Unmatched Chemical Inertness

PTFE is highly resistant to aggressive chemicals, strong acids, and solvents. This makes it an ideal choice for industries like chemical processing and pharmaceuticals.

Because it is non-reactive, the gasket does not contaminate or interact with the fluids passing through the valve, which is critical for maintaining process purity and seal integrity.

Broad Temperature Resilience

PTFE gaskets function effectively in both extremely high and low-temperature environments.

They can withstand a service temperature range from -200°C to 260°C (-328°F to 500°F). This versatility makes them suitable for everything from cryogenic applications to high-pressure steam systems.

Exceptional Resistance to Degradation

PTFE naturally resists corrosion and shows minimal wear over time, even in challenging conditions.

This inherent stability ensures the gasket remains effective for extended periods, reducing the need for frequent replacement and minimizing downtime.

Understanding the Trade-offs and Limitations

While highly durable, PTFE is not infallible. Understanding its specific limitations is crucial for successful application and avoiding premature seal failure.

The Challenge of "Cold Creep"

PTFE is susceptible to a phenomenon known as cold creep or cold flow. This is the tendency of the material to slowly deform over time when subjected to sustained pressure, even at room temperature.

This deformation can eventually compromise the tightness of the seal, particularly in high-pressure applications.

Pressure and Temperature Sensitivity

Standard PTFE performance is best suited for pressures no greater than 5 ksi. High pressurization can also lead to decompression issues, where the material fails to return to its original shape after the pressure is released.

Furthermore, while it handles a wide temperature range, it should not be exposed to rapid temperature fluctuations greater than 167°F (75°C), as this can stress the material.

Poor Performance Under Radiation

PTFE has very limited resistance to radiation. It has a maximum lifetime dose of 1×10⁴ rads, making it unsuitable for applications in nuclear or other high-radiation environments.

Making the Right Choice for Your Application

Selecting the correct gasket material requires balancing its strengths against the specific demands of your operational environment.

- If your primary focus is chemical compatibility: PTFE is an excellent choice due to its near-total chemical inertness, ensuring both process purity and gasket longevity.

- If your primary focus is extreme temperatures: PTFE is a strong candidate for both cryogenic and high-heat services, provided that pressure and temperature fluctuations remain within its specified limits.

- If your primary focus is high pressure or radiation resistance: You should look to alternative materials or specialized, filled-PTFE variants, as standard PTFE will likely fail in these conditions.

Ultimately, understanding both the exceptional strengths and the clear limitations of PTFE is the key to engineering a reliable and long-lasting sealing solution.

Summary Table:

| Property | Benefit | Limitation |

|---|---|---|

| Chemical Inertness | Resists aggressive chemicals, acids, and solvents | Not suitable for high-radiation environments (max 1×10⁴ rads) |

| Temperature Range | Operates from -200°C to 260°C (-328°F to 500°F) | Sensitive to rapid temperature changes (>75°C) |

| Cold Creep Resistance | Maintains shape under moderate pressure | Deforms under sustained high pressure (>5 ksi) |

Need a reliable PTFE sealing solution tailored to your specific application?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, gaskets, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require standard parts or custom fabrication from prototypes to high-volume orders, our expertise ensures optimal performance, longevity, and chemical compatibility.

Contact us today to discuss your project requirements and benefit from our precision production capabilities!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications