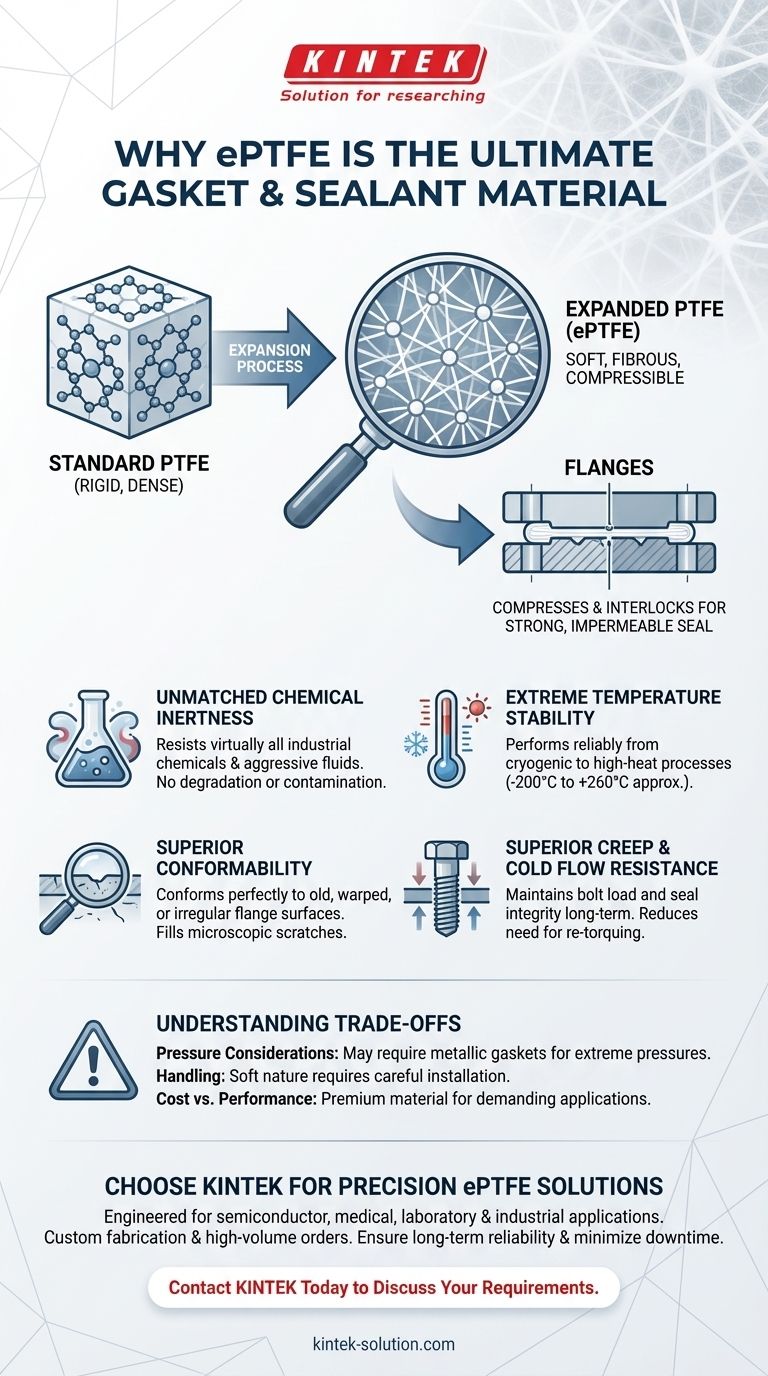

At its core, expanded PTFE (ePTFE) is an ideal gasket material because the manufacturing process transforms rigid, slippery PTFE into a soft, fibrous, and highly compressible form. This structure allows it to conform perfectly to surface imperfections while retaining PTFE's exceptional resistance to chemicals and extreme temperatures.

The key lies in its unique structure: a microscopic web of fibers that is soft and pliable when loose, but interlocks under compression to form a strong, impermeable seal that resists the common failure points of traditional gaskets.

The Structural Advantage of ePTFE

The properties that make ePTFE a superior sealant are a direct result of the expansion process, which creates a material fundamentally different from standard PTFE.

From Solid to Fibrous Web

Standard PTFE is a dense, rigid polymer. The expansion process involves stretching this material under specific conditions, which pulls the molecules apart into a microporous structure of strong fibers connected by nodes.

This creates a material that is incredibly soft and flexible when uncompressed, almost like a dense fabric.

The Power of Interlocking Fibers

When compressed between two flanges, this fibrous web collapses. The fibers and nodes interlock, creating a thin, incredibly tough, and non-porous barrier.

This mechanism allows the gasket to flow into microscopic scratches, pits, and warping on a flange face, creating a perfect, leak-free seal where a more rigid material would fail.

Key Properties for a Superior Seal

While sharing the base chemistry of PTFE, the expanded form leverages that chemistry in a more mechanically effective way for sealing applications.

Unmatched Chemical Inertness

Like all PTFE, ePTFE is chemically inert to almost all industrial fluids and aggressive chemicals. This ensures the gasket will not degrade, swell, or contaminate the process medium over its service life.

Extreme Temperature Stability

ePTFE maintains its integrity and sealing capability across an exceptionally wide temperature range, from cryogenic applications to high-heat industrial processes. It remains flexible at low temperatures and won't break down at high temperatures.

Conformability to Imperfect Surfaces

This is the standout feature of ePTFE. Its soft, compressible nature allows it to compensate for flange deformation, scratches, and pitting. It creates a highly effective seal on surfaces that are old, damaged, or complex.

Superior Resistance to Creep and Cold Flow

Creep is the tendency of a gasket material to "flow" or squeeze out from between flanges over time, especially under load and temperature. This leads to a loss of bolt torque and, eventually, a leak.

The interlocking fibrous structure of ePTFE provides excellent resistance to creep. Once compressed, it holds its shape and maintains a consistent sealing force, reducing the need for bolt re-torquing and ensuring long-term seal integrity.

Understanding the Trade-offs

While highly effective, ePTFE is not a universal solution. Understanding its limitations is key to using it correctly.

Pressure Considerations

While ePTFE forms an impermeable seal, extremely high-pressure applications may still require semi-metallic or metallic gaskets. The suitability of ePTFE depends on the specific pressure, temperature, and media combination.

Handling and Installation

The soft nature of ePTFE makes it more susceptible to damage from mishandling before installation compared to a rigid gasket. Care must be taken to ensure the sealing surface is not nicked or torn.

Cost vs. Performance

ePTFE is a premium sealing material and is typically more expensive than common non-asbestos or rubber gaskets. Its cost is justified in demanding applications where chemical resistance, temperature range, or long-term reliability are critical.

Making the Right Choice for Your Goal

Selecting ePTFE is about solving specific, challenging sealing problems that commodity gaskets cannot handle.

- If your primary focus is sealing aggressive chemicals or extreme temperatures: ePTFE provides the necessary chemical inertness and thermal stability where lesser materials would quickly fail.

- If your primary focus is achieving a seal on old, warped, or irregular flanges: The unmatched conformability of ePTFE will fill surface imperfections to create a reliable seal that is otherwise difficult to achieve.

- If your primary focus is long-term reliability and minimizing maintenance: ePTFE's superior resistance to creep ensures a stable, long-lasting seal with consistent bolt load, reducing costly leaks and downtime.

Ultimately, ePTFE excels by combining robust chemical resilience with unique physical adaptability, creating a uniquely reliable seal for demanding industrial conditions.

Summary Table:

| Property | Benefit for Sealing |

|---|---|

| Fibrous, Compressible Structure | Conforms perfectly to surface imperfections and irregular flanges. |

| Chemical Inertness | Resists virtually all industrial chemicals, preventing degradation. |

| Extreme Temperature Stability | Performs reliably from cryogenic to high-heat processes. |

| Superior Creep Resistance | Maintains bolt load and seal integrity long-term, reducing maintenance. |

Solve your toughest sealing challenges with KINTEK's precision ePTFE components.

Our expanded PTFE gaskets and seals are engineered for superior performance in the most demanding environments, including semiconductor, medical, laboratory, and industrial applications. We combine precision manufacturing with custom fabrication—from prototypes to high-volume orders—to deliver the reliable, leak-free seal you need.

Contact KINTEK today to discuss your specific requirements and let our experts provide a solution that ensures long-term reliability and minimizes downtime.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts