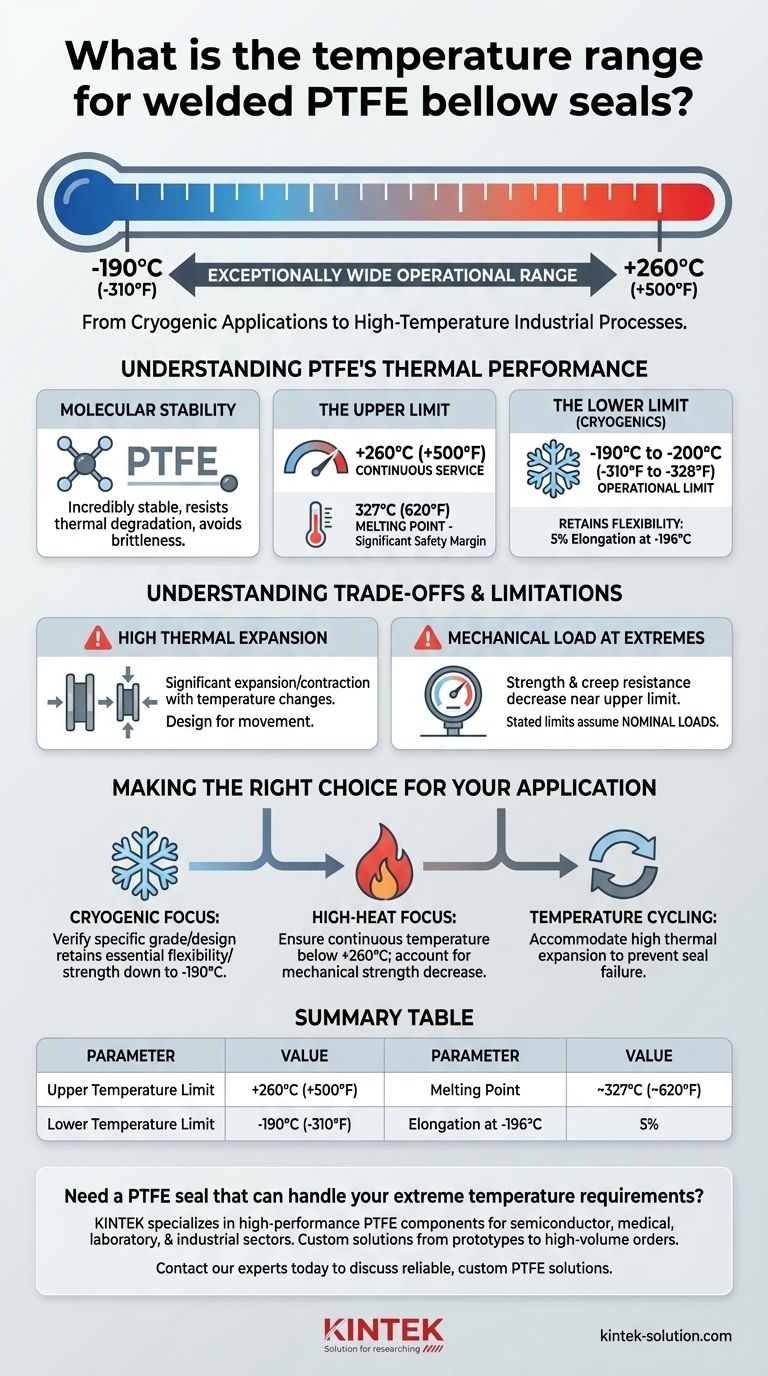

The operational temperature range for welded PTFE bellow seals is exceptionally wide, typically spanning from approximately -190°C to +260°C (-310°F to +500°F). This capability makes the material suitable for demanding environments, from cryogenic applications to high-temperature industrial processes.

While PTFE offers a vast thermal operating window, the effective temperature range in a specific application depends on the seal design, any filler materials used, and the mechanical stresses involved. The material's raw capability must always be considered within the context of the operational environment.

Understanding PTFE's Thermal Performance

Polytetrafluoroethylene (PTFE) is a fluoropolymer with unique properties that allow it to function reliably across a vast temperature spectrum. Its molecular structure is incredibly stable, resisting thermal degradation at high temperatures while avoiding the brittleness that affects many other polymers at extreme lows.

The Upper Temperature Limit

The widely accepted continuous service temperature for PTFE is +260°C (500°F). This is a practical limit for long-term, reliable operation.

It is important to note that this is well below PTFE's actual melting point, which is approximately 327°C (620°F). This high melting point provides a significant safety margin against short-term temperature spikes.

The Lower Temperature Limit (Cryogenics)

PTFE excels in cryogenic conditions, with a lower operational limit of around -190°C to -200°C (-310°F to -328°F).

Unlike many materials that become brittle and fail at such low temperatures, PTFE retains critical properties. It maintains a degree of flexibility and toughness, with data showing it can still achieve 5% elongation even at -196°C.

The Role of Material Composition

The specific grade of PTFE can influence its thermal characteristics. Virgin PTFE provides the baseline temperature range.

However, filled PTFE grades, which contain additives like glass, carbon, or bronze, can sometimes offer slightly higher temperature resistance or improved mechanical properties at the extremes. The specific filler dictates the exact performance enhancement.

Understanding the Trade-offs and Limitations

While the temperature range is impressive, selecting PTFE seals requires an understanding of its behavior under different conditions. The headline numbers do not tell the whole story.

High Coefficient of Thermal Expansion

PTFE expands and contracts more significantly with temperature changes than metals do. This high coefficient of thermal expansion is a critical design consideration.

In applications with wide temperature cycling, the housing and seal design must accommodate this movement to prevent leaks or excessive stress on the seal.

Mechanical Load at Temperature Extremes

The mechanical strength and creep resistance (resistance to slow deformation under constant load) of PTFE decrease as it approaches its upper temperature limit.

A seal operating at 250°C under high pressure will have a shorter and less reliable service life than one operating at the same temperature with minimal mechanical stress. The stated temperature limits assume nominal loads.

Seal Design vs. Material Properties

The specific geometry and function of the seal can impose different practical limits. For example, the operational range for a dynamic PTFE piston seal is often cited as a narrower -54°C to +204°C (-65°F to +400°F).

This is because the physical demands on a moving, sliding seal are different from those on a more static bellow seal. The design of the component is just as important as the properties of the material itself.

Making the Right Choice for Your Application

To ensure success, match the material's capabilities with the precise demands of your environment.

- If your primary focus is cryogenic applications: Verify that the specific PTFE grade and seal design are rated for low temperatures, as it retains essential flexibility and strength down to -190°C.

- If your primary focus is high-heat processes: Ensure your continuous operating temperature remains below +260°C and account for the potential decrease in mechanical strength under load.

- If your application involves significant temperature cycling: Work with your supplier to create a design that accommodates PTFE's high thermal expansion to prevent seal failure.

Ultimately, understanding the interplay between the material's properties and your specific operational stresses is key to ensuring reliable seal performance.

Summary Table:

| Parameter | Value |

|---|---|

| Upper Temperature Limit | +260°C (+500°F) |

| Lower Temperature Limit | -190°C (-310°F) |

| Melting Point | ~327°C (~620°F) |

| Elongation at -196°C | 5% |

Need a PTFE seal that can handle your extreme temperature requirements?

KINTEK specializes in manufacturing high-performance PTFE components, including custom bellow seals, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production and custom fabrication—from prototypes to high-volume orders—ensures you get a seal that is perfectly matched to your application's thermal and mechanical demands.

Contact our experts today to discuss how we can solve your sealing challenges with reliable, custom PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability