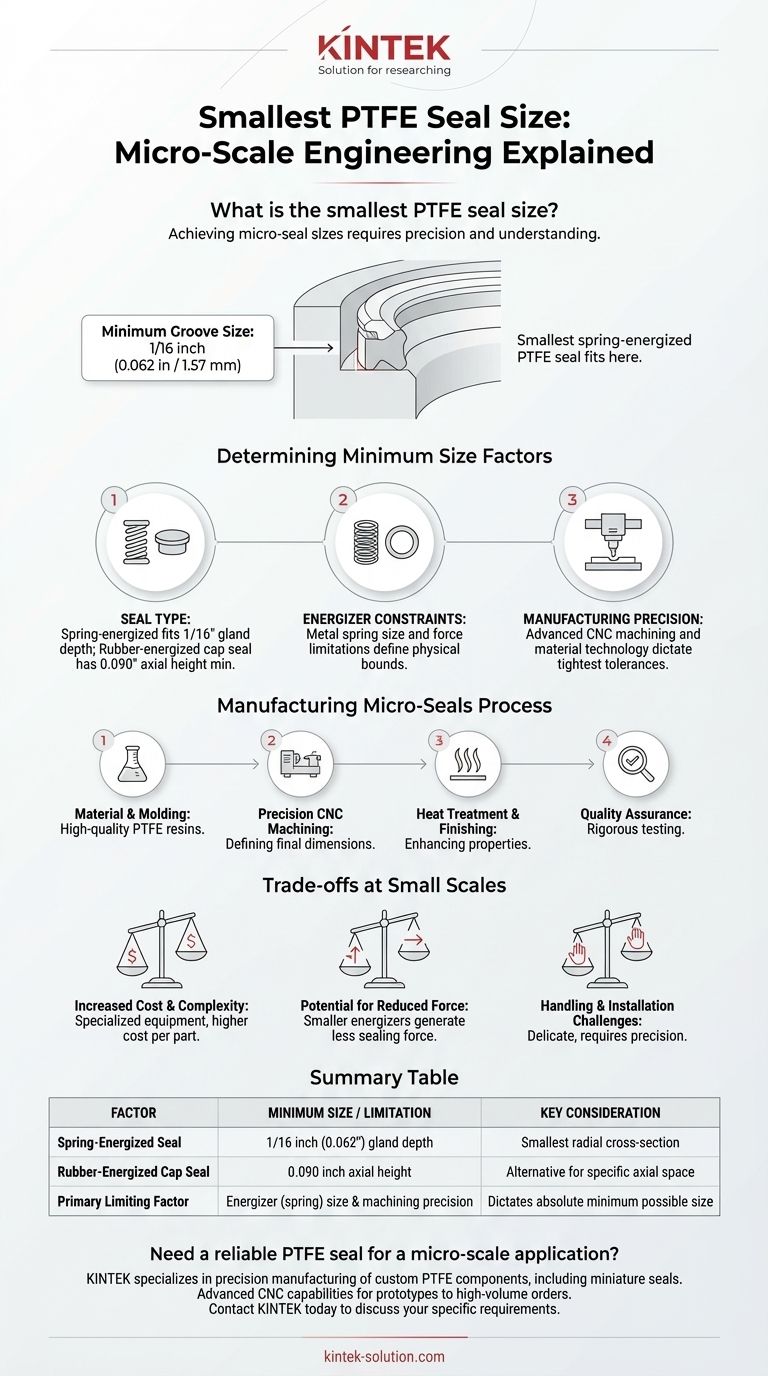

For spring-energized designs, the smallest PTFE seal can be manufactured to fit a groove as small as 1/16 inch (0.062 inches or 1.57 mm). This minimum size is not a universal standard but a function of the seal's specific type, the energizer mechanism used, and the precision of the manufacturing process.

The absolute minimum size of a PTFE seal is not a fixed number but is dictated by the specific seal design and the manufacturer's capabilities. For engineers, the critical insight is that achieving micro-seal sizes requires a deep understanding of how different components, like the energizer spring, impose physical limitations.

What Determines the Minimum Seal Size?

The theoretical limit for a PTFE seal's size is a direct result of design constraints and the physical realities of manufacturing. Several factors work together to define the smallest possible footprint.

The Role of Seal Type

Different seal designs have different minimum size requirements. A spring-energized PTFE seal, for example, can be made to fit grooves as small as 1/16 inch deep.

In contrast, a rubber-energized PTFE cap seal may have different dimensional constraints, with some capable of being produced with an axial height as small as 0.090 inches.

Energizer Constraints

For energized seals, the internal component that provides the sealing force is often the limiting factor. In a spring-energized seal, the metal spring itself has a minimum physical size below which it cannot be reliably manufactured or provide adequate force.

This energizer must be robust enough to activate the PTFE jacket and maintain a seal, establishing a hard limit on the cross-section of the entire seal assembly.

Manufacturing Precision

Ultimately, the minimum size is dictated by manufacturing technology. The process relies on creating PTFE tubing through molding or extrusion, which is then heat-treated and finished.

The final, precise dimensions are achieved with CNC machining. The sophistication of the machining equipment and the skill of the operators determine the tightest tolerances and smallest features that can be reliably produced.

The Manufacturing Process for Micro-Seals

Producing a high-quality PTFE seal, especially at a micro scale, is a multi-step, precision-controlled process.

Material Selection and Molding

The process begins with selecting high-quality PTFE resins. This raw material is then pressed and sintered into a basic shape, typically PTFE tubing, using either molding or extrusion methods.

Precision CNC Machining

This is the most critical stage for defining the seal's final dimensions. The molded PTFE tube is precisely machined on a CNC lathe to create the final seal profile, including the groove for the energizer.

Heat Treatment and Finishing

After machining, the shaped seals undergo a heat treatment process, sometimes referred to as curing or frittage. This step enhances the material's mechanical properties, durability, and temperature resistance.

Quality Assurance

For any seal, but especially for micro-seals, rigorous testing is essential. This includes dimensional verification as well as functional tests like leak and pressure checks to ensure the seal will perform reliably in its intended application.

Understanding the Trade-offs at Small Scales

Pushing the limits of size introduces practical considerations that every designer must weigh.

Increased Cost and Complexity

Manufacturing micro-seals requires highly specialized equipment and more stringent quality control. This complexity inevitably leads to a higher cost per part compared to standard-sized seals.

Potential for Reduced Force

A smaller energizer spring inherently generates less force than a larger one. While sufficient for many low-pressure applications, this may limit the seal's effectiveness in high-pressure or highly dynamic environments.

Handling and Installation Challenges

Extremely small and delicate seals require careful handling to prevent damage. The installation process is also more challenging and requires greater precision to ensure the seal is seated correctly and functions as designed.

Making the Right Choice for Your Application

Selecting the correct micro-seal depends entirely on the specific demands of your design.

- If your primary focus is achieving the absolute smallest radial cross-section: Prioritize spring-energized PTFE seals, which can fit gland depths as small as 1/16 inch (0.062").

- If your primary focus is balancing size with a specific axial height: Investigate rubber-energized PTFE cap seals, as they can offer solutions with an axial height down to 0.090".

- If your primary focus is ensuring performance and reliability: Collaborate directly with a specialized seal manufacturer to discuss their precise machining capabilities and material options for your specific application.

By understanding the relationship between seal type, energizer, and manufacturing precision, you can confidently specify a PTFE sealing solution for even the most space-constrained designs.

Summary Table:

| Factor | Minimum Size / Limitation | Key Consideration |

|---|---|---|

| Spring-Energized Seal | 1/16 inch (0.062") gland depth | Smallest radial cross-section for dynamic applications |

| Rubber-Energized Cap Seal | 0.090 inch axial height | Alternative for specific axial space constraints |

| Primary Limiting Factor | Energizer (spring) size & machining precision | Dictates the absolute minimum possible size |

Need a reliable PTFE seal for a micro-scale application?

KINTEK specializes in the precision manufacturing of custom PTFE components, including seals, liners, and labware for the semiconductor, medical, and laboratory industries. Our advanced CNC machining capabilities allow us to produce high-quality, miniature seals from prototypes to high-volume orders, ensuring the performance and reliability your design demands.

Contact KINTEK today to discuss your specific requirements and get a solution tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are some common components made from PTFE? Seals, Bearings & More for Demanding Applications

- Can PTFE rods be machined into complex shapes? Yes, with precision engineering for custom parts.

- How does PTFE Liner help in eliminating stick-slip in cable applications? Achieve Smooth, Reliable Motion

- Why is hardness important for mating parts in PTFE seals? Extend Seal Life and Prevent Failure

- What pressure ranges are common in oil and gas applications, and how do PTFE seals perform? Reliable Sealing from 1,500 to 25,000 PSI

- What are the key steps for properly installing PTFE seals? Ensure a Leak-Free, Long-Lasting Seal

- In which aerospace applications are PTFE spring-energized seals used? Ensuring Reliability in Extreme Environments

- What is a PTFE rotary seal and how is it designed? A Guide to High-Performance Sealing