Fundamentally, the low friction coefficient in PTFE processing machines is the critical property responsible for minimizing destructive heat and preventing material adhesion. This ensures the final products have smooth, high-quality surfaces while simultaneously protecting the machinery from accelerated wear and tear.

The significance of PTFE's low friction is not a single advantage but a foundational property that creates a cascade of benefits. It simultaneously protects the integrity of the material being processed while also preserving the longevity and efficiency of the machine itself.

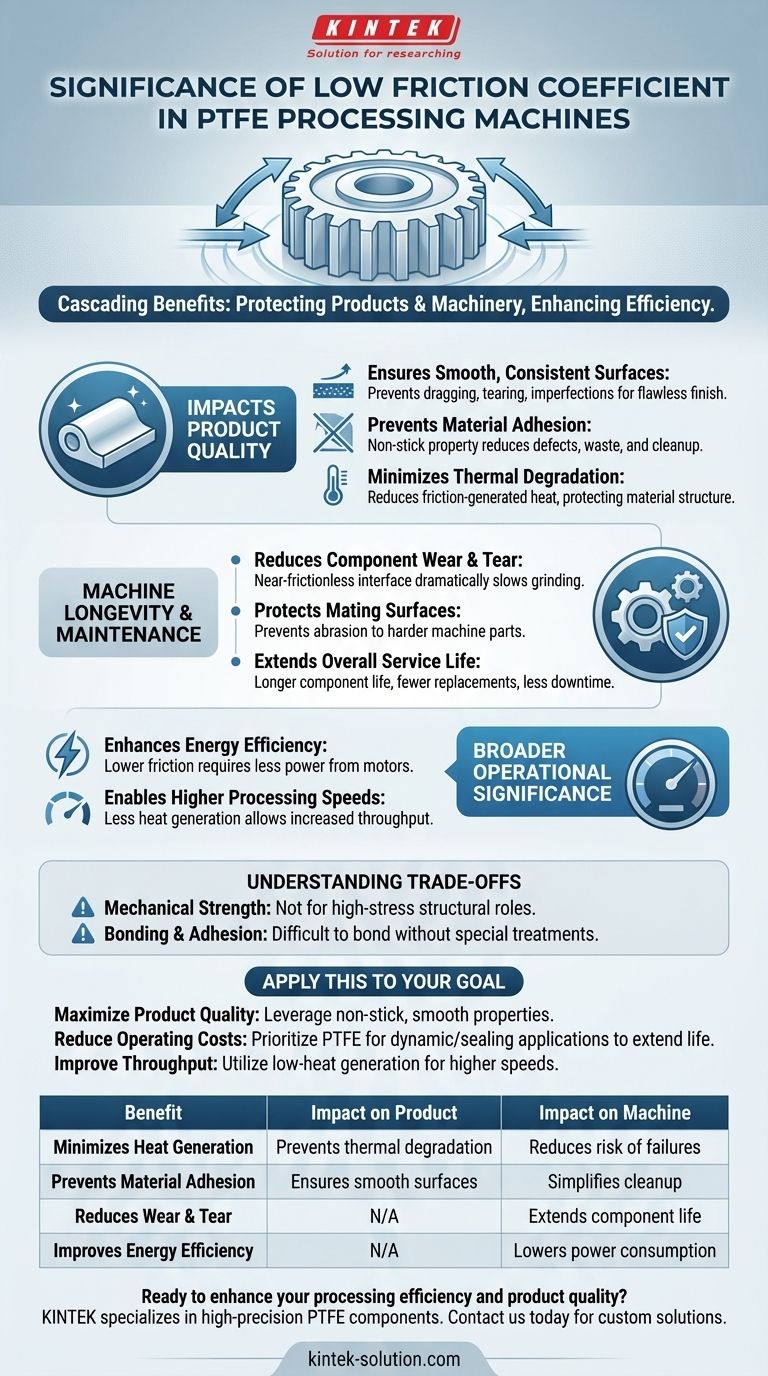

How Low Friction Directly Impacts Product Quality

The primary goal of any processing machine is to produce a high-quality, consistent output. PTFE's inherent slipperiness is a key enabler of this goal.

Ensuring Smooth, Consistent Surfaces

When materials are processed, high friction can cause dragging, tearing, and surface imperfections. PTFE’s extremely low friction allows materials to slide smoothly against machine components, resulting in a flawless finish.

Preventing Material Adhesion

PTFE is renowned for its non-stick properties. In a processing environment, this means the product is far less likely to adhere to guides, rollers, or molds, which prevents defects, reduces waste, and minimizes cleanup.

Minimizing Thermal Degradation

Friction generates heat. This thermal energy can degrade or even damage sensitive materials being processed. By minimizing friction, PTFE-based components drastically reduce heat buildup, protecting the product's intended structure and properties.

The Effect on Machine Longevity and Maintenance

Beyond the product, the low friction coefficient has a profound impact on the health and operational cost of the machine.

Reducing Component Wear and Tear

In any dynamic system, friction is the primary driver of wear. Parts that rub against each other slowly grind away, leading to failure. PTFE washers, seals, and sliding components create a near-frictionless interface that dramatically slows this process.

Protecting Mating Surfaces

The benefit extends to the parts that come into contact with the PTFE. Because PTFE is a relatively soft and smooth material, it prevents abrasion and damage to the harder, often more expensive, mating surfaces of the machine.

Extending Overall Service Life

The direct consequence of reduced wear is a longer operational life for the equipment. Components last longer, replacement cycles are extended, and the machine experiences less unscheduled downtime, lowering the total cost of ownership.

Understanding the Trade-offs

While immensely beneficial, the properties of PTFE are not universally ideal for every application. Objectivity requires acknowledging its limitations.

Mechanical Strength

PTFE is not a high-strength structural material. In applications requiring extreme load-bearing capacity, it may deform or fail where a metallic component would not. It excels at low-friction surfaces, not high-stress structural roles.

Bonding and Adhesion

The same non-stick property that is so valuable in processing can make it difficult to bond PTFE to other materials. Attaching PTFE components often requires special surface treatments or mechanical fastening, adding a layer of complexity to machine design.

The Broader Operational Significance

The impact of low friction extends beyond product quality and machine life into overall operational efficiency.

Enhancing Energy Efficiency

Overcoming friction requires energy. By minimizing the frictional forces within a machine, motors and actuators consume less power to perform the same amount of work. This leads to tangible energy savings, especially in continuous, high-volume operations.

Enabling Higher Processing Speeds

Because less heat is generated, machinery can often be run at higher speeds without risking thermal damage to the product or components. This increases throughput and overall productivity.

How to Apply This to Your Goal

Your specific objective determines which aspect of PTFE's low friction is most critical to your operation.

- If your primary focus is maximizing product quality: Leverage PTFE's non-stick, smooth surface properties to eliminate processing defects and ensure a perfect finish.

- If your primary focus is reducing long-term operating costs: Prioritize the use of PTFE in all dynamic and sealing applications to extend component life, minimize maintenance, and reduce energy consumption.

- If your primary focus is improving throughput: Utilize the low-heat generation of PTFE components to safely increase machine speeds and boost overall production efficiency.

Ultimately, leveraging PTFE's low friction is a strategic decision to enhance quality, extend equipment life, and optimize operational efficiency.

Summary Table:

| Benefit | Impact on Product | Impact on Machine |

|---|---|---|

| Minimizes Heat Generation | Prevents thermal degradation of materials | Reduces risk of heat-related failures |

| Prevents Material Adhesion | Ensures smooth, defect-free surfaces | Simplifies cleanup and reduces downtime |

| Reduces Wear & Tear | N/A | Extends component life and lowers maintenance costs |

| Improves Energy Efficiency | N/A | Lowers power consumption for motors and actuators |

Ready to enhance your processing efficiency and product quality?

KINTEK specializes in manufacturing high-precision PTFE components—including seals, liners, and custom labware—that leverage a low friction coefficient to protect your materials and machinery. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our custom fabrication services from prototypes to high-volume orders can help you achieve superior surface finishes, extend equipment life, and reduce operational costs.

Contact us today to discuss how our PTFE solutions can be tailored to your specific processing goals!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability