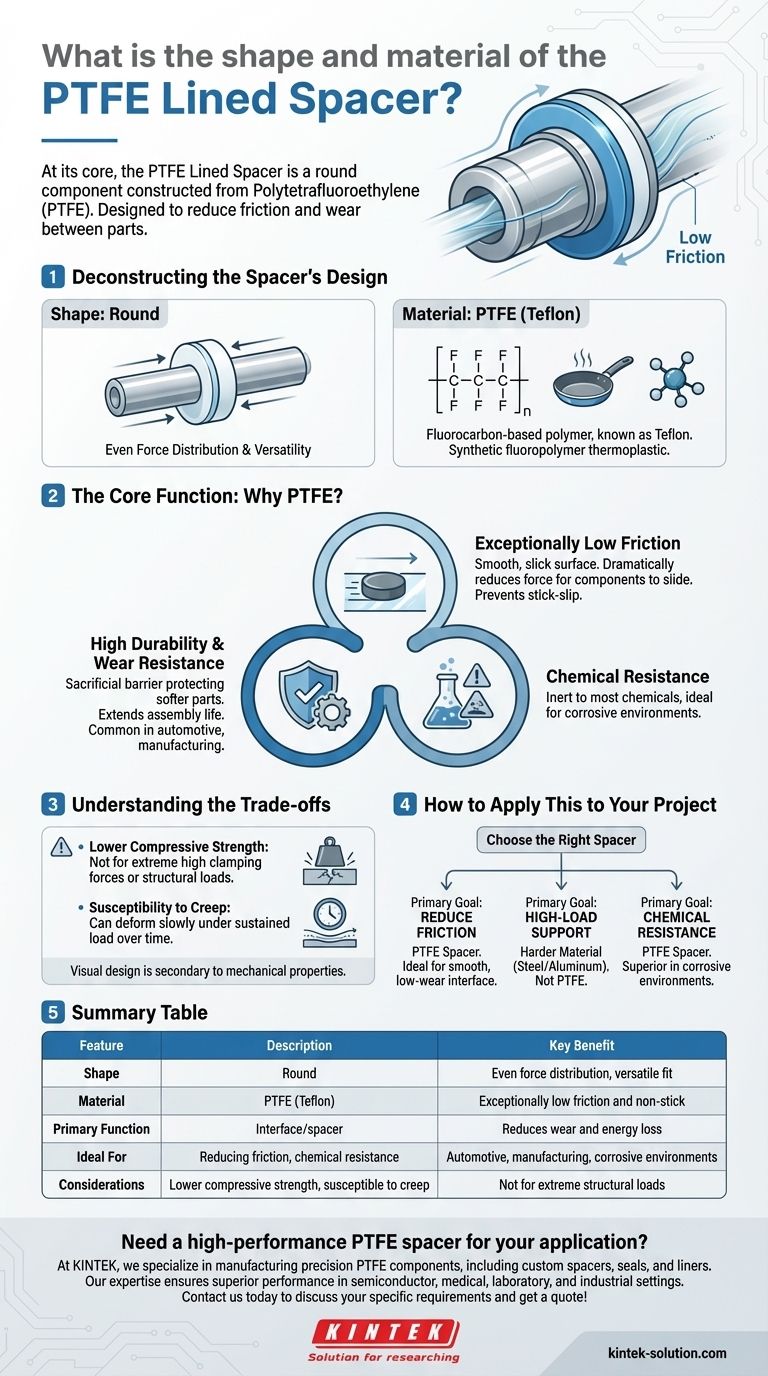

At its core, the PTFE Lined Spacer is a round component constructed from Polytetrafluoroethylene (PTFE). This specific combination of shape and material is not arbitrary; it is engineered to serve a distinct purpose in mechanical and industrial systems by providing a smooth, durable, and low-friction interface between other components.

This spacer is designed to solve a fundamental engineering challenge: reducing friction and wear between moving or stationary parts. Its simple round shape and the unique properties of its PTFE material create a highly effective barrier in demanding applications.

Deconstructing the Spacer's Design

To understand the spacer's value, we must look at its two defining characteristics: its geometry and its material composition.

The Significance of the Round Shape

The spacer is intentionally round. This is the most common and versatile shape for this type of component, as it fits easily over shafts, bolts, and pins.

A round profile ensures that clamping or rotational forces are distributed evenly around the component's circumference, preventing stress concentrations at corners that could lead to premature failure.

Understanding the Material: PTFE

The spacer is made from Polytetrafluoroethylene (PTFE), a fluorocarbon-based polymer.

You most likely know this material by its common trade name: Teflon. It is a synthetic fluoropolymer thermoplastic valued for its unique set of properties.

The Core Function: Why PTFE is the Material of Choice

The selection of PTFE is critical to the spacer's function. The material imparts several key performance benefits that make it ideal for its intended applications.

Exceptionally Low Friction

PTFE is famous for its non-stick properties, which stem from its incredibly low coefficient of friction. This means it creates a smooth, slick surface that dramatically reduces the force required for components to slide against each other.

This property is essential for reducing operational energy loss and preventing the stick-slip phenomenon in moving assemblies.

High Durability and Wear Resistance

The spacer provides a durable surface that protects softer or more expensive components from direct contact and wear. By acting as a sacrificial barrier, it extends the service life of the entire assembly.

Its use is common in the automotive, manufacturing, and general machinery industries where reliability is paramount.

Understanding the Trade-offs and Considerations

While highly effective, no material is perfect for every scenario. Understanding the limitations of PTFE is key to proper application.

Lower Compressive Strength

Compared to metal spacers, PTFE is a softer material. It is not designed for applications requiring extremely high clamping forces or structural load-bearing, as it can deform under intense pressure.

Susceptibility to Creep

Under a sustained load over a long period, PTFE can exhibit "creep," which is a tendency to slowly and permanently deform. This must be factored into designs where precise, long-term dimensional stability under load is critical.

Visual Design vs. Function

Some spacers feature a multicolor design. While this can add visual appeal or be used for part identification, it is a secondary characteristic. The component's primary value is derived entirely from its mechanical and material properties, not its appearance.

How to Apply This to Your Project

Choosing the right spacer requires aligning the component's properties with your primary engineering goal.

- If your primary focus is reducing friction: The PTFE spacer is an ideal choice for creating a smooth, low-wear interface between moving parts.

- If your primary focus is high-load structural support: You should consider a spacer made from a harder material, such as steel or aluminum.

- If your primary focus is chemical resistance: PTFE's inertness makes it a superior choice for use in corrosive environments where metals would fail.

By understanding the distinct advantages and limitations of PTFE, you can confidently specify the correct component for your engineering challenge.

Summary Table:

| Feature | Description | Key Benefit |

|---|---|---|

| Shape | Round | Even force distribution, versatile fit |

| Material | PTFE (Teflon) | Exceptionally low friction and non-stick |

| Primary Function | Interface/spacer between components | Reduces wear and energy loss |

| Ideal For | Reducing friction, chemical resistance | Automotive, manufacturing, corrosive environments |

| Considerations | Lower compressive strength, susceptible to creep | Not for extreme structural loads |

Need a high-performance PTFE spacer for your application?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom spacers, seals, and liners. Whether you need a standard solution or a custom-fabricated part for prototypes or high-volume orders, our expertise ensures a component that delivers superior performance in semiconductor, medical, laboratory, and industrial settings.

Contact us today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What size range do PTFE balls come in? A Guide from 3mm to 100mm

- What are the key features of Teflon balls? Unlock Superior Performance in Demanding Environments

- What temperature range can PTFE balls withstand? Unlock Extreme Thermal Stability from -200°C to 260°C

- What are the common applications of PTFE balls? Leverage Unmatched Chemical Resistance & Low Friction

- What materials are used for PTFE balls? A Guide to Virgin PTFE vs. Filled Composites