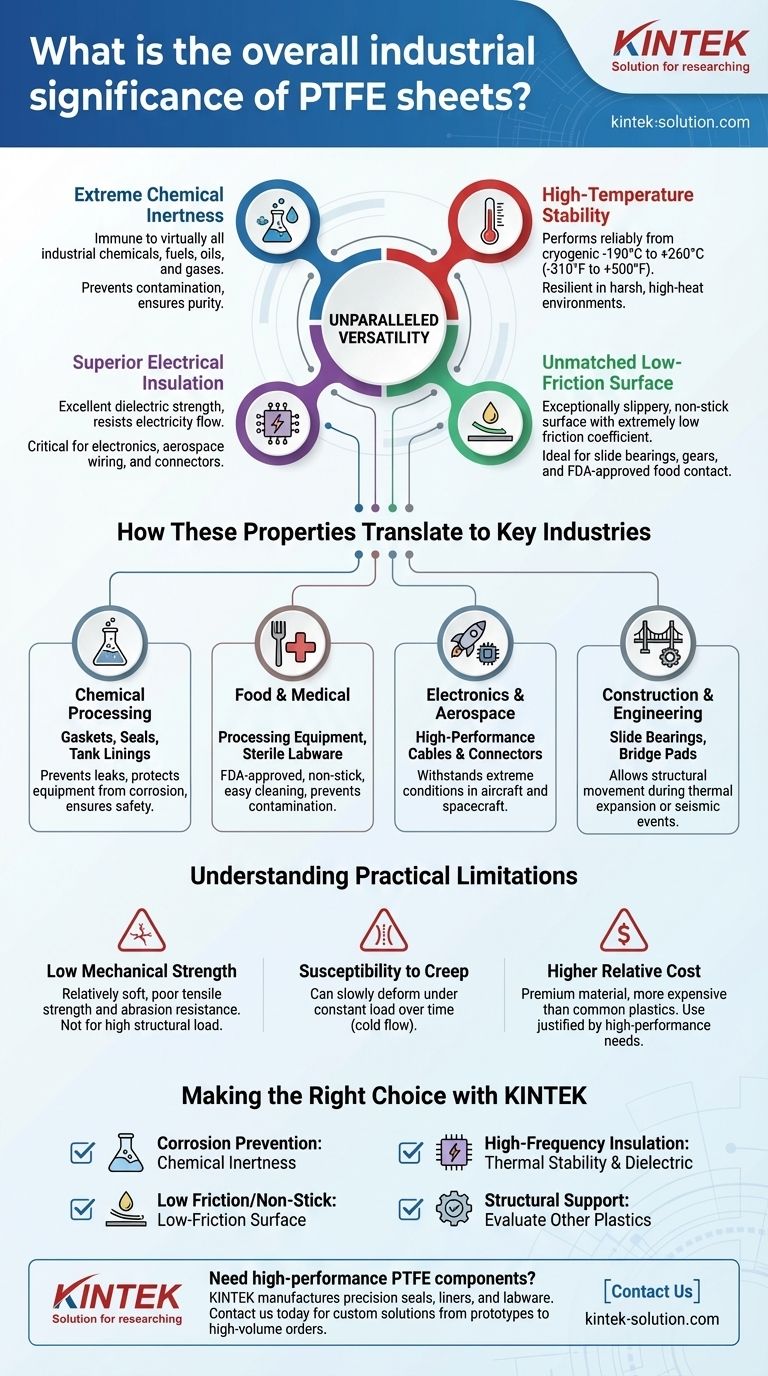

The industrial significance of PTFE sheets stems from their unparalleled versatility. This material, a synthetic fluoropolymer also known by the brand name Teflon, solves critical operational challenges across nearly every major industry. Its value comes from a rare combination of properties—including extreme chemical resistance, high-temperature stability, and low friction—that make it indispensable in demanding environments where other materials would fail.

PTFE's industrial importance is not based on a single attribute, but on its unique fusion of capabilities. It provides extreme chemical inertness, high-temperature stability, excellent electrical insulation, and an exceptionally low-friction surface, making it the default high-performance material for the most challenging industrial applications.

The Core Properties Driving Industrial Adoption

The widespread use of PTFE is a direct result of its exceptional physical and chemical characteristics. Understanding these core properties is key to appreciating its role in modern industry.

Extreme Chemical Inertness

PTFE is virtually immune to degradation from almost all industrial chemicals, fuels, oils, and gases. This makes it an essential material for containing and handling corrosive substances.

Its inertness prevents contamination, ensuring product purity in sensitive processes like pharmaceutical production and food processing.

High-Temperature Stability

PTFE sheets perform reliably across an exceptionally wide temperature range, from cryogenic conditions at -190°C up to +260°C (-310°F to +500°F).

This thermal resilience allows it to be used in high-heat industrial processes and harsh environments where most other plastics would melt or become brittle.

Superior Electrical Insulation

PTFE exhibits very high dielectric strength, meaning it is an excellent electrical insulator. It resists the flow of electricity and maintains its insulating properties even at high frequencies.

This makes it a critical component in the electronics, aerospace, and electrical industries for wiring, connectors, and circuit boards.

Unmatched Low-Friction Surface

With one of the lowest coefficients of friction of any solid material, PTFE creates an exceptionally slippery, non-stick surface.

This property is fundamental for applications requiring smooth movement without lubrication, such as in slide bearings, gears, and non-stick coatings. Its FDA approval also makes it safe for food contact surfaces.

How These Properties Translate to Key Industries

The theoretical properties of PTFE become significant when applied to solve real-world problems across diverse sectors.

In Chemical Processing

The material's chemical resistance makes it ideal for gaskets, seals, and tank linings. These components prevent leaks and protect equipment from corrosion, ensuring operational safety and longevity.

In Food & Medical

Being both FDA-approved and chemically inert, PTFE is used extensively for food processing equipment where its non-stick surface simplifies cleaning and prevents contamination. In labs, it's used for sterile, non-reactive containers and tubing.

In Electronics & Aerospace

PTFE's combination of high-temperature resistance and superior electrical insulation is critical for manufacturing high-performance cables and connectors that can withstand extreme conditions in aircraft and spacecraft.

In Construction & Engineering

Large sheets of PTFE are used as slide bearings in heavy construction, such as bridges and large buildings. These pads allow structures to move slightly during thermal expansion or seismic events, reducing stress on the framework.

Understanding the Practical Limitations

No material is perfect. While PTFE offers exceptional performance, its selection requires acknowledging its inherent trade-offs. This objectivity is critical for successful engineering.

Low Mechanical Strength

Compared to other engineering plastics, PTFE is relatively soft and has poor tensile strength and abrasion resistance. It is not suitable for applications requiring high structural integrity or load-bearing capacity on its own.

Susceptibility to Creep

Under a constant, sustained load, PTFE can slowly deform over time. This phenomenon, known as creep or "cold flow," must be carefully considered in the design of components like gaskets and seals to prevent failure.

Higher Relative Cost

PTFE is a premium performance material and is generally more expensive than common plastics like nylon or polyethylene. Its use is typically justified only when its specific, high-performance properties are a strict requirement for the application.

Making the Right Choice for Your Application

To leverage PTFE effectively, align its unique strengths with your primary engineering goal.

- If your primary focus is corrosion prevention: PTFE's unmatched chemical inertness makes it the ideal choice for linings, gaskets, and seals in aggressive chemical environments.

- If your primary focus is high-frequency electrical insulation: Its low dielectric constant and thermal stability make it a superior material for critical electronic and aerospace components.

- If your primary focus is reducing friction without lubrication: PTFE's exceptionally low friction coefficient is perfect for creating maintenance-free slide bearings and non-stick surfaces.

- If your primary focus is structural support under high load: You should evaluate other engineering plastics, as PTFE's mechanical strength and resistance to creep are key limiting factors.

Ultimately, understanding PTFE's unique profile of strengths and weaknesses allows engineers to solve problems that few other materials can address.

Summary Table:

| Property | Key Benefit | Industrial Application |

|---|---|---|

| Extreme Chemical Inertness | Resists corrosion & contamination | Chemical processing gaskets, seals, tank linings |

| High-Temperature Stability | Performs from -190°C to +260°C | Aerospace components, high-heat processes |

| Superior Electrical Insulation | Excellent dielectric strength | Electronics, wiring, connectors |

| Low-Friction Surface | Non-stick, reduces wear without lubrication | Slide bearings, food processing equipment |

Need high-performance PTFE components for your specialized application?

At KINTEK, we manufacture precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication ensures you get the exact solution, from prototypes to high-volume orders, that leverages PTFE's unique properties to solve your most demanding operational challenges.

Contact us today to discuss your project requirements and discover how our PTFE solutions can enhance your product performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability