While some sources state a single maximum velocity, the true speed limit for a PTFE piston seal is not a fixed number. It is a dynamic variable that depends fundamentally on system pressure, temperature, and the specific PTFE compound being used. A conservative value for general-purpose reciprocating applications might be around 3 ft/sec (1 m/s), but this can be significantly higher or lower based on operating conditions.

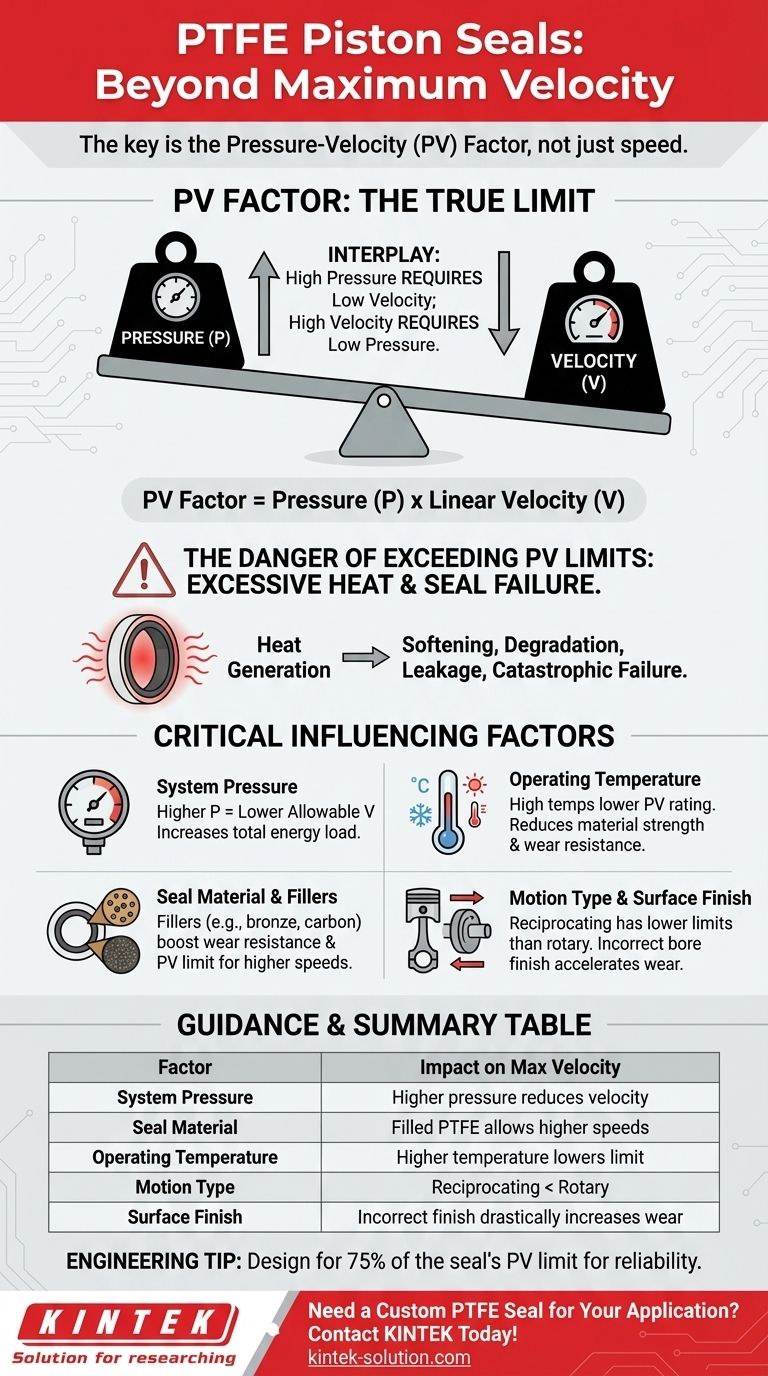

The concept you need to master is not maximum velocity, but the Pressure-Velocity (PV) factor. This value represents the combined load on the seal and is the true determinant of its performance limit. Focusing only on velocity while ignoring pressure is a direct path to premature seal failure.

Beyond a Single Number: Introducing the PV Factor

To select a seal that will survive in your application, you must move beyond a simple velocity rating and understand the interplay between pressure and speed.

What is the PV Factor?

The PV factor is the product of the system's operating pressure (P) and the seal's linear velocity (V). It represents the amount of energy and heat being generated at the sealing interface per unit of area.

Every seal material, including different grades of PTFE, has a maximum PV rating, which defines its operational limits.

How Pressure and Velocity Interact

Think of pressure and velocity as being on opposite ends of a seesaw. To keep the system in balance (i.e., below the material's PV limit), if one goes up, the other must come down.

You can have a system with very high pressure moving at a low velocity. Or, you can have a low-pressure system moving at a high velocity. Attempting to run at both high pressure and high velocity simultaneously will almost certainly exceed the PV limit.

The Critical Role of Heat

Exceeding the PV limit generates excessive frictional heat. This heat is the primary enemy of the seal, causing the PTFE material to soften, degrade, and rapidly wear away, leading to leakage and catastrophic failure.

Key Factors That Influence Velocity Limits

The theoretical PV rating is just the starting point. The real-world maximum velocity is influenced by several critical system parameters.

System Pressure

This is the "P" in the PV equation. Higher operating pressures directly reduce the allowable velocity for a given seal material, as the total energy load increases proportionally.

Operating Temperature

PTFE has a wide operating temperature range (e.g., -65°F to +400°F), but its mechanical properties change within that range. At higher temperatures, PTFE's compressive strength and wear resistance decrease, effectively lowering its maximum PV rating and thus its allowable speed.

Seal Material and Fillers

Pure PTFE is rarely used for dynamic piston seals. Instead, it is blended with fillers like bronze, carbon, glass fiber, or graphite. These fillers dramatically improve wear resistance, reduce thermal expansion, and increase thermal conductivity, allowing the seal to handle a much higher PV value and, consequently, higher speeds.

Reciprocating vs. Rotary Motion

The context of the motion is critical. High-speed figures (e.g., up to 30 m/s) typically refer to rotary shaft seals, where a stable hydrodynamic lubrication film is easier to maintain. Reciprocating piston seals experience constant stops, starts, and reversals, which disrupt this film, placing more stress on the seal and generally resulting in lower maximum velocity limits.

Understanding the Trade-offs and Risks

Choosing and implementing a PTFE seal requires awareness of its operational boundaries to ensure system reliability.

The Danger of Ignoring PV Limits

Simply choosing a seal based on a generic "max velocity" without calculating the PV factor for your specific application is the most common cause of failure. This leads to accelerated wear, high friction, and unexpected system downtime.

Impact of Mating Surface Finish

The finish of the cylinder bore or piston rod is crucial. A surface that is too rough will act like a file, abrading the seal. A surface that is too smooth can prevent the retention of a proper lubricant film, increasing friction and heat. Always adhere to the seal manufacturer's specifications for surface finish.

Misinterpreting Generic Data

The 3.2 ft/sec value cited in some references is a highly conservative guideline, likely for an unfilled PTFE seal under moderate pressure. It is not a universal limit. Conversely, a 30 m/s value is for a completely different application type (rotary). Relying on either without context is misleading.

How to Determine the Right Velocity Limit for Your Application

The only reliable method is to use the manufacturer's data for the specific seal you are considering. Consult their technical datasheets and PV charts.

- If your primary focus is high-speed, low-pressure applications: You can likely achieve speeds well above the conservative 3 ft/sec guideline, but you must select a filled PTFE compound and verify that your P x V calculation is well within the manufacturer's published limits.

- If your primary focus is high-pressure, moderate-speed applications: Your maximum velocity will be strictly limited by the pressure. Prioritize a PTFE seal with fillers (like bronze) designed for high compressive strength and extrusion resistance.

- If your primary focus is ultimate reliability and safety: Always design your system to operate at 75% or less of the seal's rated PV limit. This safety margin accounts for unforeseen temperature spikes, pressure fluctuations, and lubrication issues.

Always consult the seal manufacturer's specific PV charts to make an informed and reliable engineering decision.

Summary Table:

| Factor | Impact on Maximum Velocity |

|---|---|

| System Pressure (P) | Higher pressure significantly reduces allowable velocity. |

| Seal Material & Fillers | Filled PTFE (e.g., bronze, carbon) allows for much higher speeds. |

| Operating Temperature | Higher temperatures lower the PV limit, reducing maximum speed. |

| Motion Type (Reciprocating vs. Rotary) | Reciprocating motion generally has lower velocity limits than rotary. |

| Mating Surface Finish | Incorrect finish can drastically increase wear and heat, limiting speed. |

Need a PTFE Seal That Can Handle Your Specific Pressure and Velocity Requirements?

At KINTEK, we understand that your application's success depends on a seal that is precisely engineered for its unique operating conditions—not just a generic speed rating. Our expertise in custom PTFE fabrication ensures you get a component that balances pressure, velocity, and temperature for optimal performance and longevity.

We provide:

- Custom-Formulated PTFE Compounds: Tailored with fillers like bronze, carbon, or glass to maximize your PV limit and withstand high-speed or high-pressure demands.

- Precision Engineering: From prototypes to high-volume production, we manufacture seals that meet exact specifications for surface finish, tolerances, and durability.

- Expert Guidance: Our team will help you analyze your PV requirements to select or design a seal that ensures reliability and prevents premature failure.

Don't risk downtime from seal failure. Let KINTEK engineer a solution for your semiconductor, medical, laboratory, or industrial application.

Contact us today for a consultation and quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How do rubber bellows compare to PTFE bellows? Choose the Right Expansion Joint for Your System

- What are PTFE-lined plug valves and their primary purpose? Achieve Superior Control for Corrosive & High-Purity Fluids

- How are Teflon sheets used in embroidery? Achieve Professional Results with a Simple Tool

- Why is tool selection important in the CNC machining of PTFE parts? Achieve Precision and Quality

- What are the installation benefits of expanded PTFE gaskets? Achieve Reliable Seals on Imperfect Flanges

- What are the advantages of PTFE-lined pipes? Achieve Unmatched Corrosion Resistance and Purity

- Why are ePTFE gaskets suitable for food and pharmaceutical industries? Ensure Product Purity and Compliance

- What types of cutting tools are recommended for machining PTFE? Achieve Clean Cuts and Tight Tolerances