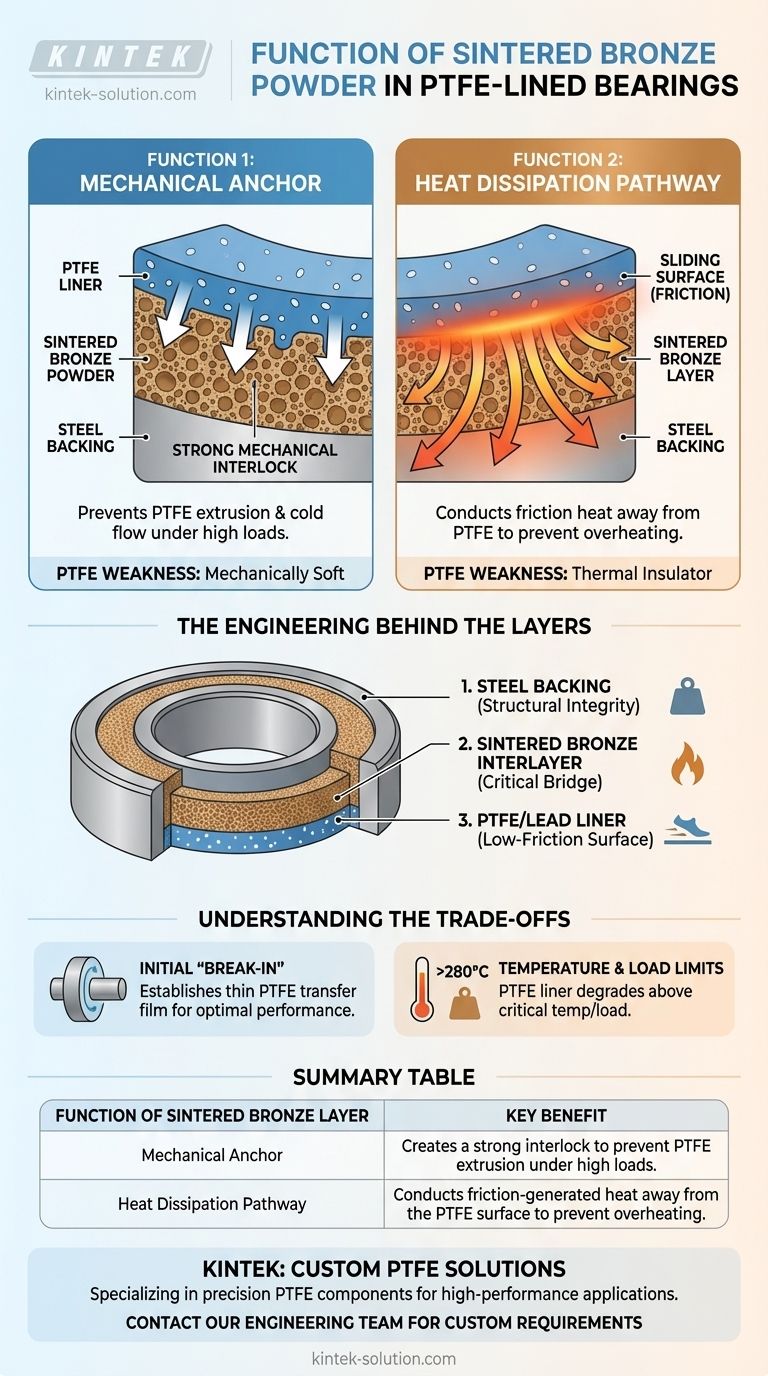

In short, the sintered bronze powder serves two critical functions: it creates a strong mechanical lock for the soft PTFE liner and provides an essential path for heat to escape from the bearing surface. This ingenious layer is what allows the bearing to handle high loads and dissipate friction-generated heat effectively.

PTFE is an excellent low-friction material but is structurally weak and a poor thermal conductor. The sintered bronze powder is the crucial interlayer that solves both of these problems, enabling the use of PTFE in demanding mechanical applications.

The Engineering Behind the Layers

To understand the role of the bronze, you must first understand the fundamental problem this type of bearing is designed to solve. Engineers want the incredibly low friction of a material like PTFE, but they need the strength and durability of a metal like steel. A composite bearing achieves this by combining materials in distinct layers, each with a specific job.

The Problem with Pure PTFE

Polytetrafluoroethylene (PTFE) is famous for its extremely low coefficient of friction. However, as a standalone bearing material, it has significant weaknesses.

It is mechanically soft and prone to "cold flow," meaning it can deform and get squeezed out of place under sustained pressure. It is also a thermal insulator, which means it traps the heat generated by friction, leading to overheating and rapid failure.

The Solution: A Multi-Layer System

PTFE-lined bearings overcome these limitations with a three-part structure:

- Steel Backing: This provides the overall structural integrity, rigidity, and strength to handle heavy loads and press-fitting into a housing.

- Sintered Bronze Interlayer: This is the critical bridge between the steel and the PTFE.

- PTFE/Lead Liner: This is the actual sliding surface that provides the low-friction performance.

The Two Functions of Sintered Bronze

The bronze layer is not a solid piece of metal. It is created by sintering—a process where bronze powder is heated and compacted to fuse it into a solid, but porous, sponge-like structure. This porous nature is the key to its function.

Function 1: A Reservoir and Mechanical Anchor

The soft PTFE liner needs to be locked securely to the steel backing. The porous, sponge-like bronze layer acts as the perfect anchor.

During manufacturing, the PTFE mixture is forced into the voids and pores of the sintered bronze. This creates a powerful mechanical interlock, holding the PTFE liner in place and preventing it from being extruded or wiped away under high loads or oscillating movements.

Function 2: A Pathway for Heat Dissipation

Friction, even low friction, generates heat. Since the PTFE layer is an insulator, that heat has nowhere to go and can quickly destroy the bearing surface.

Bronze, however, is an excellent thermal conductor. The sintered bronze layer acts as a heat sink, drawing thermal energy away from the sliding surface and transferring it to the steel backing, which can then dissipate it into the surrounding housing. This prevents the PTFE from reaching its critical temperature limit.

Understanding the Trade-offs

While this composite design is highly effective, it's important to recognize its operational boundaries.

The Initial "Break-In" Period

These bearings establish a thin "transfer film" of PTFE on the mating shaft during the first few cycles of operation. This is a normal and necessary process for achieving optimal low-friction performance.

Temperature and Load Limits

The bronze layer drastically improves performance, but it doesn't eliminate the inherent limits of the PTFE. If the operational temperature exceeds the PTFE's limit (typically around 280°C / 536°F), the liner will degrade. Similarly, extreme loads can still cause deformation over time.

How This Design Influences Your Application

The function of the sintered bronze layer directly translates to the bearing's suitability for different jobs.

- If your primary focus is high-load capacity: The bronze layer's ability to mechanically anchor the PTFE is the key feature that allows the bearing to resist deformation under pressure.

- If your primary focus is higher-speed or continuous operation: The thermal conductivity of the bronze is critical for dissipating heat and ensuring a long service life.

- If your primary focus is maintenance-free reliability: The entire composite structure, with the bronze locking in the self-lubricating PTFE, provides a "set and forget" solution.

This clever use of material science allows engineers to create a single component that combines the best properties of its constituent parts.

Summary Table:

| Function of Sintered Bronze Layer | Key Benefit |

|---|---|

| Mechanical Anchor | Creates a strong interlock to prevent PTFE extrusion under high loads. |

| Heat Dissipation Pathway | Conducts friction-generated heat away from the PTFE surface to prevent overheating. |

Need a custom PTFE-lined bearing solution for your high-performance application?

KINTEK specializes in manufacturing precision PTFE components, including custom-fabricated seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in material science ensures your bearings deliver optimal performance under high loads and in demanding thermal environments.

Contact our engineering team today to discuss your specific requirements—from prototype development to high-volume production.

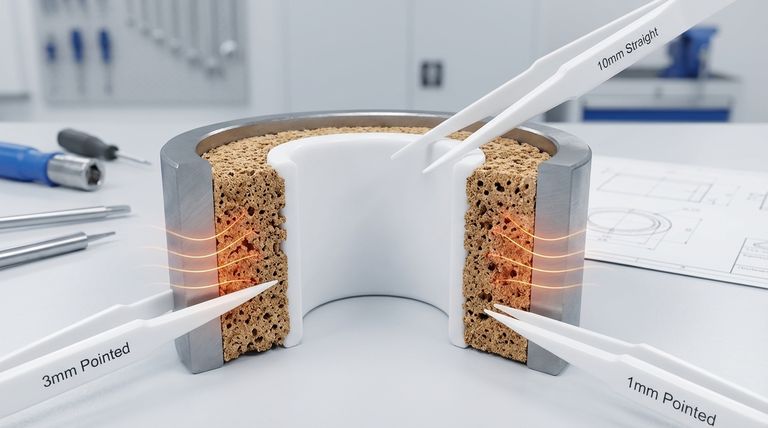

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining