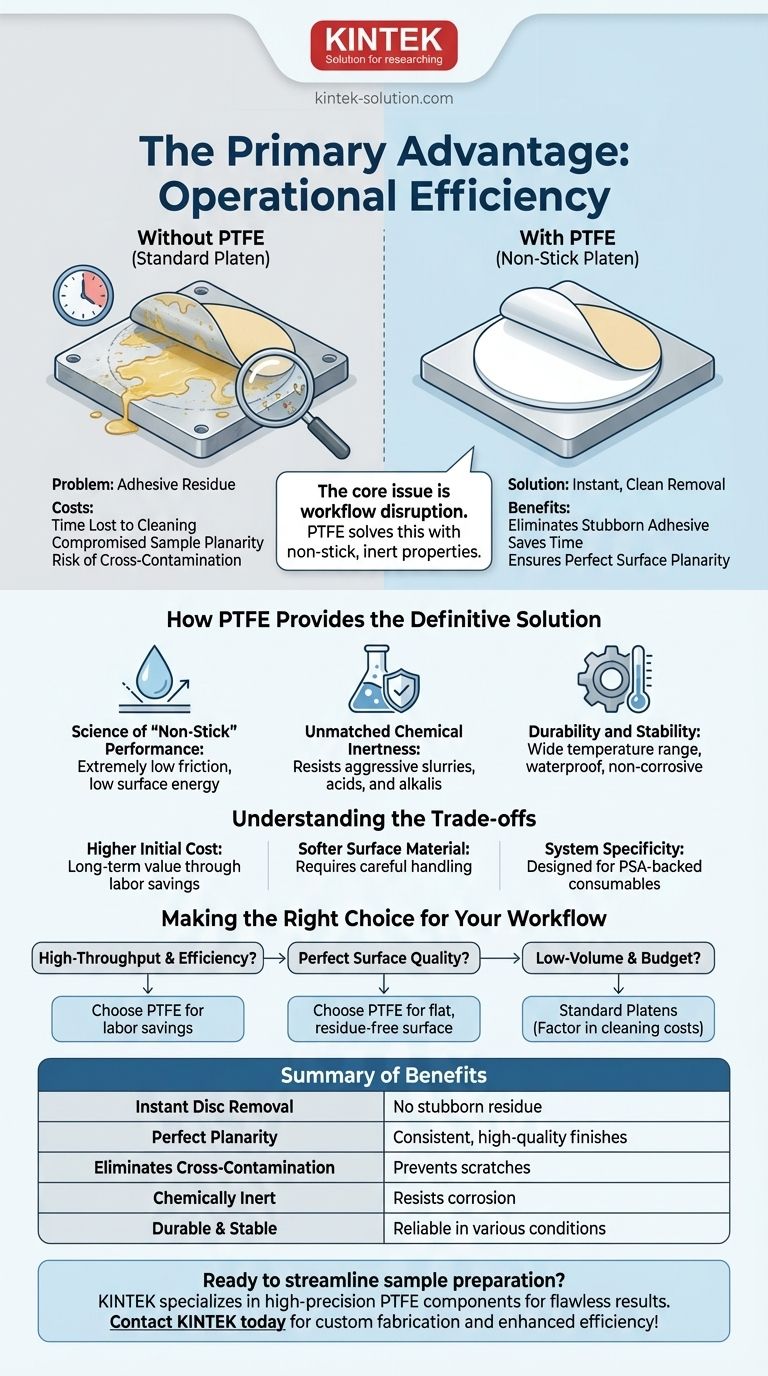

The primary advantage is operational efficiency. Using a PTFE ferromagnetic support disc with adhesive-backed consumables allows for the instant, clean removal of abrasive discs or polishing cloths after use. The exceptionally non-stick nature of PTFE means no stubborn adhesive residue is left behind, eliminating the need for time-consuming cleaning and solvent use between steps.

The core issue these discs solve is not just the inconvenience of a sticky surface, but the hidden costs of workflow disruption. Adhesive residue compromises sample quality, consumes valuable time, and introduces process variability, all of which are eliminated by the non-stick, inert properties of a PTFE interface.

The Core Problem: The Hidden Costs of Adhesive Residue

In any precision grinding or polishing workflow, the surface of the support platen is a critical reference plane. When using standard metallic platens with adhesive-backed consumables, the leftover adhesive creates significant and often underestimated problems.

Time Lost to Cleaning

After an abrasive disc is used, peeling it off a metal platen almost always leaves behind a layer of sticky adhesive. This residue must be meticulously scraped off or dissolved with solvents, a process that adds minutes of non-productive time to every single abrasive change.

Compromised Sample Planarity

Even small amounts of leftover adhesive create high spots on the platen. When the next disc is applied, it will not sit perfectly flat. This uneven surface directly translates to a non-planar finish on your sample, compromising the integrity of your preparation.

Risk of Cross-Contamination

Old adhesive residue can trap abrasive particles from the previous step. When you move to a finer grit, these coarser, trapped particles can be reintroduced, causing deep scratches and ruining a delicate polishing stage. This forces you to either re-grind the sample or accept a flawed result.

How PTFE Provides the Definitive Solution

A PTFE-faced disc is not simply a convenience; it is an engineered solution that leverages the unique properties of Polytetrafluoroethylene (PTFE) to solve the fundamental problems of adhesive transfer and surface integrity.

The Science of "Non-Stick" Performance

PTFE has one of the lowest coefficients of friction of any solid material (0.05 to 0.10). Its surface energy is incredibly low, meaning other materials—including aggressive adhesives—have almost nothing to bond to. This is why the adhesive backing of a polishing cloth peels away effortlessly, leaving a perfectly clean surface every time.

Unmatched Chemical Inertness

Polishing processes often use chemical-mechanical slurries that can be acidic, alkaline, or contain complex chemical agents. A standard metal platen can corrode or react over time. PTFE is almost completely inert and resistant to virtually all industrial chemicals, ensuring the support disc will not degrade, stain, or corrode.

Durability and Stability

PTFE maintains its properties across a wide operational temperature range (from -325°F to +500°F), easily withstanding the frictional heat generated during grinding. It is also waterproof and non-corrosive, so it will not warp or degrade in the wet environment of a materials lab, guaranteeing dimensional stability over its entire lifespan.

Understanding the Trade-offs

While highly effective, it's important to view PTFE support discs within the context of their specific application.

Higher Initial Cost

A PTFE-faced ferromagnetic disc represents a higher upfront investment compared to a simple, plain metal platen. Its value is realized over time through labor savings and improved process reliability, making it a return-on-investment calculation.

Softer Surface Material

While durable, PTFE is a polymer and is softer than steel or aluminum. Dropping a sharp-edged sample or a tool directly onto the face can scratch or gouge the surface. This requires a reasonable degree of care during handling to maintain a pristine, flat reference plane.

System Specificity

These discs are designed as an interface for consumable discs or cloths that have a pressure-sensitive adhesive (PSA) backing. They are not a universal solution for systems that use different mounting methods, such as plain-back discs that rely on a separate magnetic carrier.

Making the Right Choice for Your Workflow

To determine if this is the right solution, consider the primary goal of your preparation process.

- If your primary focus is high-throughput and efficiency: The time saved by eliminating cleaning makes PTFE discs a critical investment that pays for itself in reduced labor.

- If your primary focus is achieving perfect surface quality and planarity: The guaranteed flat, residue-free surface provided by PTFE is non-negotiable for preventing defects and ensuring reliable results.

- If your primary focus is managing a low-volume lab on a tight budget: You can continue with standard platens, but you must factor in the recurring cost of solvents and technician time dedicated to cleaning.

Adopting PTFE support discs fundamentally transforms a recurring point of failure into a seamless and reliable component of your process.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Instant Disc Removal | No stubborn adhesive residue left on the platen. |

| Perfect Planarity | Ensures a flat surface for consistent, high-quality sample finishes. |

| Eliminates Cross-Contamination | Prevents grit from previous steps from scratching samples. |

| Chemically Inert | Resists corrosion from acids, alkalis, and polishing slurries. |

| Durable & Stable | Maintains performance across a wide temperature range and in wet environments. |

Ready to eliminate adhesive residue and streamline your sample preparation?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including ferromagnetic support discs, for semiconductor, medical, laboratory, and industrial applications. Our discs are engineered to deliver the non-stick performance and chemical resistance you need for flawless results.

We offer custom fabrication from prototypes to high-volume orders, ensuring you get the exact solution for your workflow.

Contact KINTEK today to discuss your requirements and see how our PTFE components can enhance your efficiency and sample quality!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Parts Manufacturer PTFE Magnetic Stirring Bar

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications