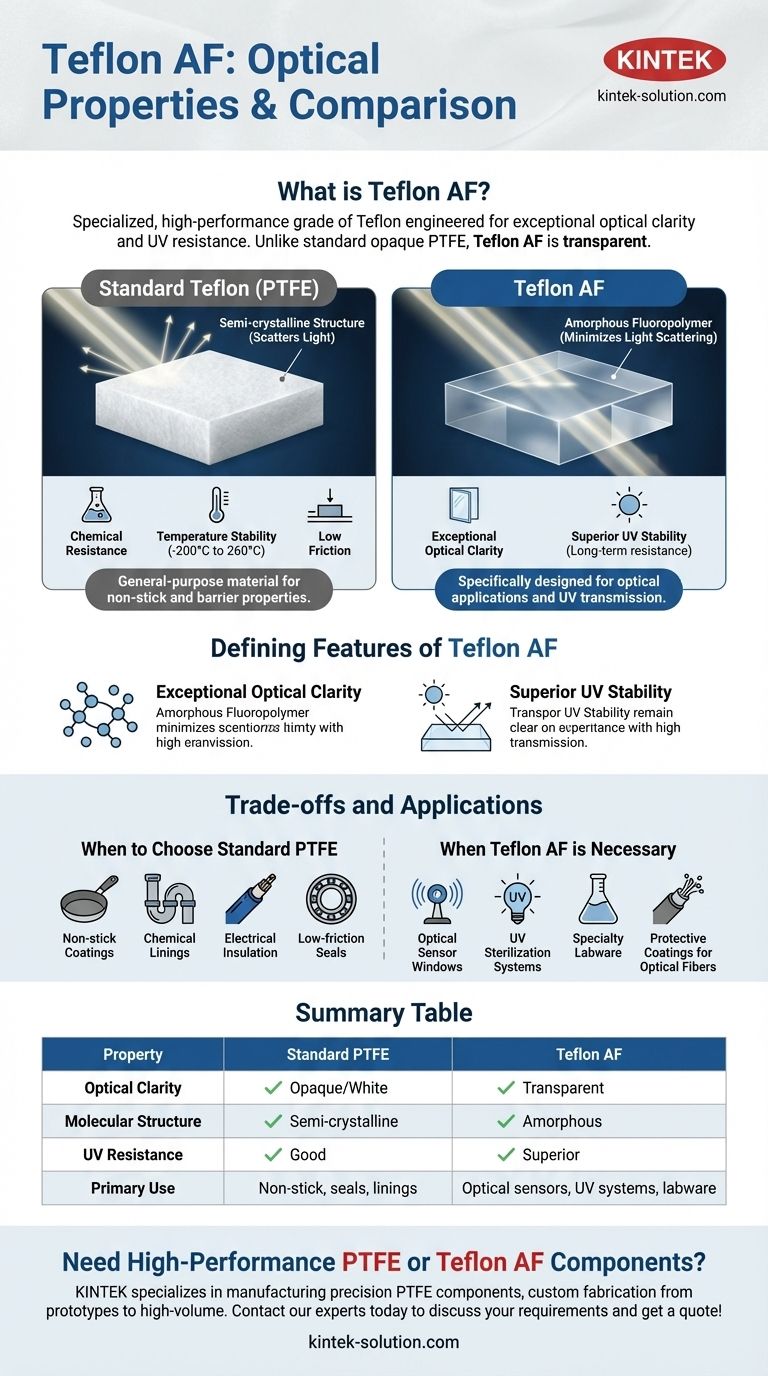

In short, Teflon AF is a specialized, high-performance grade of Teflon engineered for exceptional optical clarity and resistance to ultraviolet (UV) light. Unlike standard Teflon (PTFE), which is typically opaque and white, Teflon AF is transparent, allowing it to be used in applications where light transmission is critical.

The crucial distinction is that while all Teflon variants offer chemical inertness and temperature resistance, Teflon AF is specifically designed for optical applications, whereas standard PTFE is a general-purpose material valued for its non-stick and barrier properties.

What is Standard Teflon (PTFE)?

To understand Teflon AF, we must first establish a baseline with the material most people simply call "Teflon."

The Core Material

Standard Teflon is the brand name for polytetrafluoroethylene (PTFE), a synthetic fluoropolymer discovered in 1938.

It is composed of only carbon and fluorine atoms, forming extremely strong bonds that give the material its remarkable stability.

Key Properties of PTFE

PTFE is renowned for a unique combination of characteristics, making it a staple in industrial and consumer applications.

These properties include extreme chemical resistance, stability across a wide temperature range (-200°C to 260°C), and an exceptionally low coefficient of friction, which creates its famous non-stick surface.

Typical Appearance

A critical point of comparison is that standard PTFE is a semi-crystalline polymer. This crystalline structure scatters light, rendering the material opaque and typically white in its natural state.

The Defining Features of Teflon AF

Teflon AF was developed to solve a problem that standard PTFE could not: the need for a material with Teflon's chemical and thermal stability that was also optically clear.

Exceptional Optical Clarity

The "AF" in Teflon AF stands for Amorphous Fluoropolymer. Unlike the semi-crystalline structure of PTFE, Teflon AF has an amorphous (non-crystalline) molecular structure.

This disordered arrangement allows light to pass through with minimal scattering, resulting in high transparency across a wide spectrum of light, including visible and UV wavelengths.

Superior UV Stability

Many transparent plastics can degrade, yellow, or become brittle when exposed to long-term ultraviolet radiation.

Teflon AF's robust chemical structure makes it inherently resistant to UV degradation. It maintains its optical clarity and mechanical integrity even after prolonged exposure, a critical feature for outdoor or UV-centric applications.

Understanding the Trade-offs and Applications

Choosing between standard PTFE and Teflon AF depends entirely on the specific requirements of the application, as they are not interchangeable.

When to Choose Standard PTFE

Standard PTFE is the ideal choice for applications where its core strengths are paramount and optical properties are irrelevant.

This includes non-stick coatings for cookware, chemical-resistant linings for pipes and vessels, electrical insulation, and low-friction seals or bearings. It is a well-established and cost-effective solution for these challenges.

When Teflon AF is Necessary

Teflon AF is specified for advanced applications where transparency is a non-negotiable design requirement.

Its unique combination of optical clarity, UV stability, and chemical inertness makes it suitable for optical sensor windows, components in UV sterilization systems, specialty labware, and protective coatings for optical fibers.

Key Considerations

As a specialty material, Teflon AF generally has a different cost profile and may require different processing techniques compared to the commodity grades of standard PTFE. The choice is a classic engineering trade-off between performance requirements and budget.

Making the Right Choice for Your Application

Selecting the correct material requires a clear understanding of your project's primary goal.

- If your primary focus is creating a non-stick surface or a chemical barrier: Standard PTFE is the proven, economical, and correct choice.

- If your primary focus is optical transparency or transmitting UV light: Teflon AF is the only variant specifically engineered to meet these demanding requirements.

Ultimately, understanding this fundamental difference empowers you to select the precise fluoropolymer engineered to solve your specific technical challenge.

Summary Table:

| Property | Standard PTFE | Teflon AF |

|---|---|---|

| Optical Clarity | Opaque/White | Transparent |

| Molecular Structure | Semi-crystalline | Amorphous |

| UV Resistance | Good | Superior |

| Primary Use | Non-stick, seals, linings | Optical sensors, UV systems, labware |

Need High-Performance PTFE or Teflon AF Components?

KINTEK specializes in manufacturing precision PTFE components (seals, liners, labware) and can advise on material selection for your specific optical, semiconductor, medical, or industrial application. We offer custom fabrication from prototypes to high-volume orders, ensuring your project benefits from the right material properties.

Contact our experts today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry