At its core, PTFE Spiral Wrap is a flexible, helically cut tube made from Polytetrafluoroethylene (PTFE). It is designed to be wrapped around wires, cables, hoses, and tubes to provide an exceptional layer of protection. Its primary function is to shield these critical components from abrasion, impact, corrosive chemicals, and extreme temperatures, thereby extending their operational lifespan.

The true value of PTFE Spiral Wrap is not simply bundling cables; it's about deploying a high-performance protective shield in demanding environments where standard materials would quickly degrade and fail. It translates the unique chemical and thermal resilience of PTFE into a versatile, easy-to-apply format.

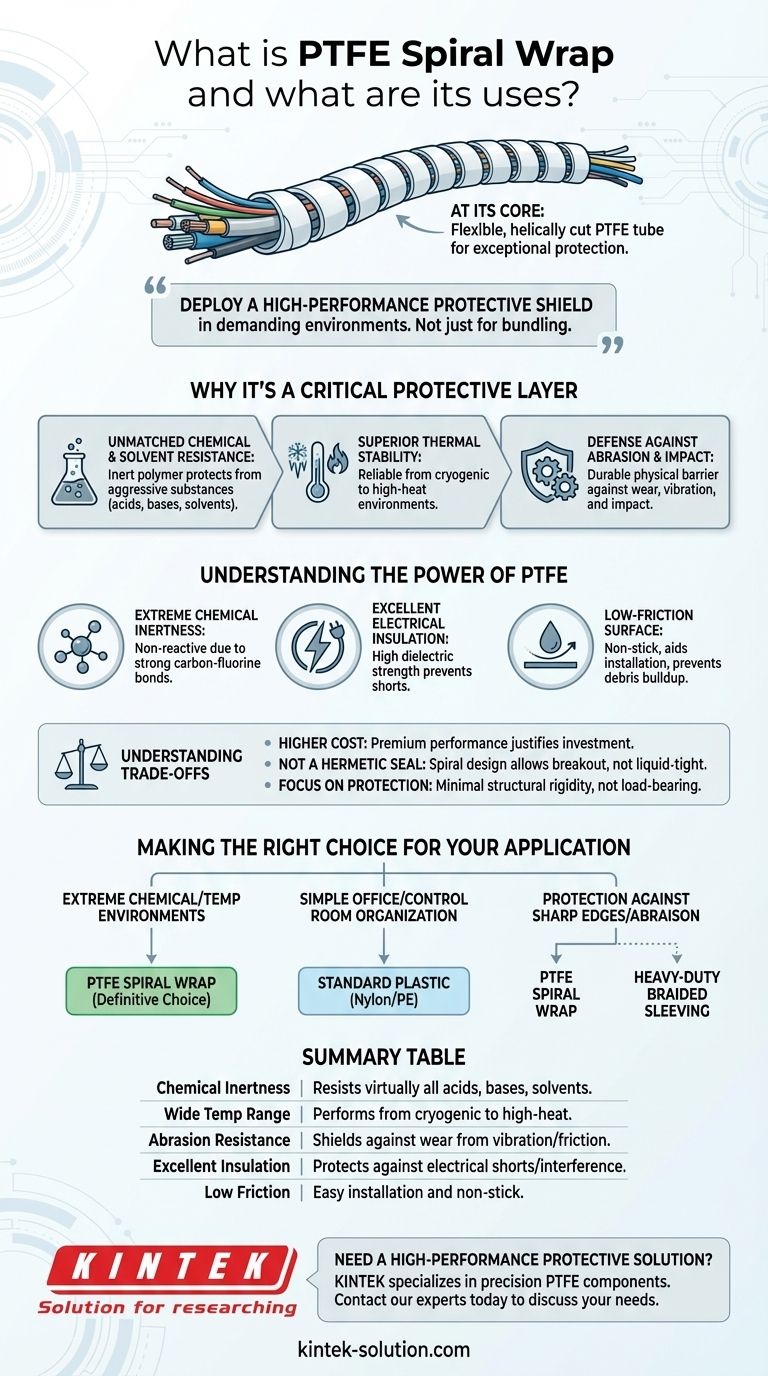

Why PTFE Spiral Wrap is a Critical Protective Layer

PTFE Spiral Wrap provides a multi-faceted defense system for the components it encases. Its effectiveness stems directly from the inherent properties of the PTFE material from which it is made.

Unmatched Chemical and Solvent Resistance

PTFE is one of the most chemically inert polymers known. This means a spiral wrap made from it can protect lines and wires from a vast range of aggressive substances, including acids, bases, and solvents, which would corrode or dissolve other plastics.

Superior Thermal Stability

This wrap performs reliably across an exceptionally wide temperature range. It remains flexible and effective in cryogenic applications as well as in high-temperature environments, such as near engines or exhaust systems, where other materials would become brittle or melt.

Defense Against Abrasion and Impact

The wrap acts as a durable, physical barrier. It protects sensitive hoses and cable jackets from the wear and tear of vibration, friction against other surfaces, and incidental impacts, preventing costly damage and system downtime.

Understanding the Power of PTFE

To grasp why this wrap is so effective, you must understand the material itself. Polytetrafluoroethylene is an engineered fluoropolymer with a unique combination of properties that make it ideal for challenging industrial, medical, and scientific applications.

Extreme Chemical Inertness

The strong carbon-fluorine bonds in PTFE's molecular structure make it non-reactive with nearly all chemicals. This is why it is used for gaskets, vessel linings, and chemical-resistant tubing in the most aggressive processing environments.

Excellent Electrical Insulation

PTFE has a very high dielectric strength, making it an outstanding electrical insulator. This property is critical when the spiral wrap is used to bundle and protect electrical wires and data cables, preventing shorts and signal interference.

Low-Friction Surface

Famously known for its non-stick properties (e.g., Teflon coatings), PTFE has an extremely low coefficient of friction. For a spiral wrap, this aids in an easier installation process and prevents debris or other materials from sticking to the bundled assembly.

Understanding the Trade-offs

While highly effective, PTFE Spiral Wrap is a specialized solution. Understanding its limitations is key to using it correctly.

Higher Cost Compared to Standard Plastics

PTFE is a premium, high-performance polymer. Its cost is significantly higher than that of common materials like polyethylene or nylon. Its use is justified by performance requirements, not budget constraints.

Not a Hermetic Seal

The spiral design is excellent for allowing wires or tubes to break out from the bundle at any point. However, this also means it does not provide a true hermetic seal against liquid ingress unless it is wrapped with a significant overlap, which increases material usage.

Focus on Protection, Not Structure

PTFE Spiral Wrap is designed for sheathing and protection. It offers minimal structural rigidity and should not be relied upon to support the weight of the bundle or to function as a load-bearing component.

Making the Right Choice for Your Application

Selecting the correct wrap depends entirely on your operational environment and performance goals.

- If your primary focus is survival in extreme chemical or temperature environments: PTFE Spiral Wrap is the definitive choice for protecting critical lines where failure is not an option.

- If your primary focus is simple cable organization in a standard office or control room: A less expensive nylon or polyethylene spiral wrap will likely be sufficient and more cost-effective.

- If your primary focus is protecting against sharp edges or frequent abrasion: PTFE offers excellent protection, but also consider heavy-duty braided sleeving as a potential alternative.

By understanding its unique properties, you can deploy PTFE Spiral Wrap strategically to ensure the long-term reliability of your most critical systems.

Summary Table:

| Key Property | Benefit for Your Application |

|---|---|

| Chemical Inertness | Resists virtually all acids, bases, and solvents. |

| Wide Temperature Range | Performs from cryogenic to high-heat environments. |

| Abrasion Resistance | Shields against wear from vibration and friction. |

| Excellent Insulation | Protects against electrical shorts and interference. |

| Low Friction | Easy installation and non-stick surface. |

Need a high-performance protective solution for your critical components?

KINTEK specializes in manufacturing precision PTFE components, including custom spiral wraps, for the semiconductor, medical, laboratory, and industrial sectors. We understand the demands of extreme environments and can fabricate a solution tailored to your specific needs—from prototypes to high-volume orders.

Contact our experts today to discuss how our PTFE Spiral Wrap can extend the lifespan and reliability of your systems.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability