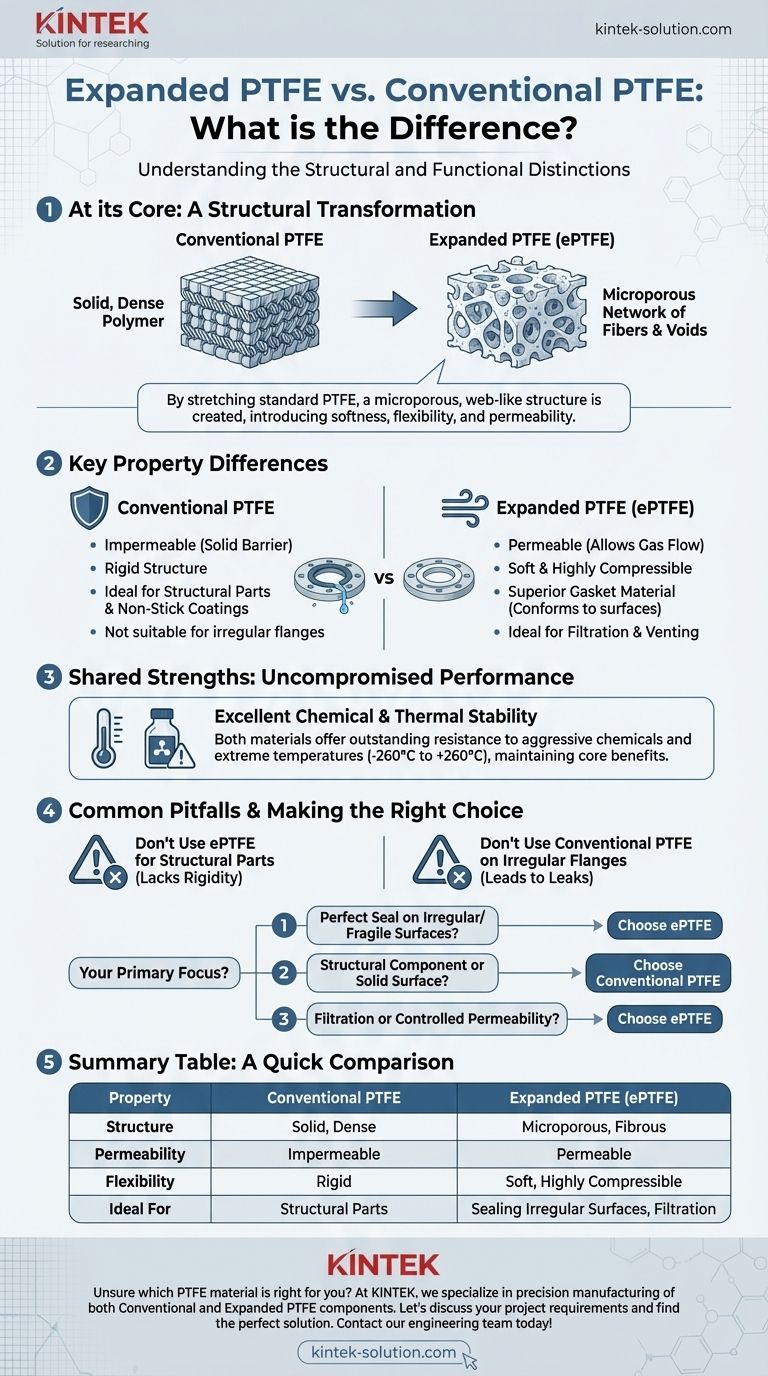

At its core, expanded PTFE (ePTFE) is a structurally modified version of conventional Polytetrafluoroethylene (PTFE). While standard PTFE is a solid, dense polymer, ePTFE is processed to create a microporous structure of fibers and voids. This fundamental change transforms the material from a relatively rigid plastic into a soft, flexible, and permeable material, unlocking entirely new applications while retaining PTFE's legendary performance characteristics.

The critical difference between ePTFE and conventional PTFE lies in its physical structure. By introducing a microporous, mesh-like network, ePTFE gains softness, flexibility, and permeability while retaining the exceptional chemical and thermal resistance of standard PTFE.

From Solid to Sponge: The Structural Transformation

The unique properties of ePTFE are a direct result of its manufacturing process. Understanding this transformation from a solid polymer to a microporous web is key to selecting the right material for your needs.

Conventional PTFE: The Solid Foundation

Standard PTFE, widely known by the brand name Teflon®, is a solid fluoropolymer. It is valued for being dense and non-porous.

This solid structure gives it high dielectric strength and makes it an excellent material for machined parts, non-stick coatings, and solid gaskets where a rigid barrier is required.

The Expansion Process: A Microporous Network

Expanded PTFE is created by physically stretching conventional PTFE under specific conditions.

This process pulls the polymer's molecules apart, forming a web-like structure of incredibly fine fibers interconnected by nodes. The result is a material that is mostly empty space, or pores.

The Result: A Fundamentally Different Material

This new microporous structure gives ePTFE a unique physical character. It is exceptionally soft, compressible, and flexible.

Many describe its texture as being similar to a smooth, spongy marshmallow, a stark contrast to the harder, more rigid feel of solid PTFE.

Key Property Differences and Their Implications

While both materials share the same base chemistry, their structural differences lead to vastly different performance characteristics in certain applications.

Permeability vs. Impermeability

This is the most significant functional difference. The network of pores makes ePTFE permeable, allowing gases like air to pass through it. This makes it ideal for high-performance filters and venting applications.

Conventional PTFE is impermeable, acting as a solid barrier to both liquids and gases.

Flexibility and Gasket Performance

The soft, spongy nature of ePTFE makes it a superior gasket material, especially for delicate or uneven surfaces. It can easily conform to imperfections in flanges, creating a tight seal with less bolt pressure.

This is critical for fragile equipment, such as glass-lined flanges in the chemical industry, where a hard gasket could cause damage. It is also highly resistant to creep and cold flow, maintaining its seal over time.

Shared Strengths: Chemical and Thermal Stability

Crucially, the expansion process does not compromise PTFE's core benefits.

Both ePTFE and conventional PTFE offer outstanding chemical resistance across a wide range of aggressive media. They also function efficiently across an extreme temperature range, from cryogenic conditions up to +260°C (+500°F).

Common Pitfalls to Avoid

Choosing between these two materials requires understanding their distinct strengths. A common mistake is treating them as interchangeable.

Don't Use ePTFE for Structural Parts

The softness and compressibility of ePTFE make it unsuitable for applications that require structural rigidity or load-bearing capability. For machined blocks, rods, or insulators, conventional PTFE is the correct choice.

Don't Use Conventional PTFE on Irregular Flanges

Using a rigid, conventional PTFE gasket on a warped, scratched, or fragile flange is a common cause of leaks. The material cannot conform to surface imperfections the way ePTFE can, leading to an incomplete seal.

Making the Right Choice for Your Application

Your final decision should be guided entirely by the specific demands of your project.

- If your primary focus is creating a perfect seal on irregular or fragile surfaces: Choose ePTFE for its unmatched compressibility and ability to conform to imperfections.

- If your primary focus is a structural component or a solid, non-stick surface: Conventional PTFE is the correct choice due to its rigidity and solid, non-porous form.

- If your primary focus is an application requiring filtration or controlled permeability: ePTFE is the only option of the two, as its microporous structure is designed for this purpose.

Understanding this fundamental structural difference is the key to leveraging the right material for your specific engineering challenge.

Summary Table:

| Property | Conventional PTFE | Expanded PTFE (ePTFE) |

|---|---|---|

| Structure | Solid, Dense, Non-Porous | Microporous, Fibrous Network |

| Permeability | Impermeable (Solid Barrier) | Permeable (Allows Gas Flow) |

| Flexibility | Rigid | Soft, Spongy, Highly Compressible |

| Ideal For | Structural Parts, Non-Stick Coatings | Sealing Irregular Surfaces, Filtration, Venting |

| Shared Strengths | Excellent Chemical & Thermal Resistance (-260°C to +260°C) | Excellent Chemical & Thermal Resistance (-260°C to +260°C) |

Unsure which PTFE material is right for your application?

At KINTEK, we specialize in the precision manufacturing of both conventional PTFE and expanded PTFE (ePTFE) components. Whether you need rigid, machined parts for structural integrity or soft, conformable seals for delicate flanges, our expertise ensures you get the optimal material and design for your specific needs in the semiconductor, medical, laboratory, or industrial sectors.

We provide:

- Expert Material Selection Guidance to solve your unique challenges.

- Custom Fabrication from prototypes to high-volume production runs.

- Superior Quality with a focus on precision and performance.

Let's discuss your project requirements and find the perfect PTFE solution. Contact our engineering team today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability