At its core, the use of Teflon encapsulated O-rings is driven by industries that cannot afford seal failure in the face of aggressive chemicals. Key sectors include chemical processing, pharmaceuticals, semiconductor manufacturing, and oil and gas, where these seals provide a critical barrier against corrosive acids, solvents, and bases that would destroy standard elastomers.

The fundamental advantage of a Teflon encapsulated O-ring is its dual nature: it combines the near-universal chemical inertness of a seamless Teflon shell with the reliable, compressive sealing force of an energized rubber core.

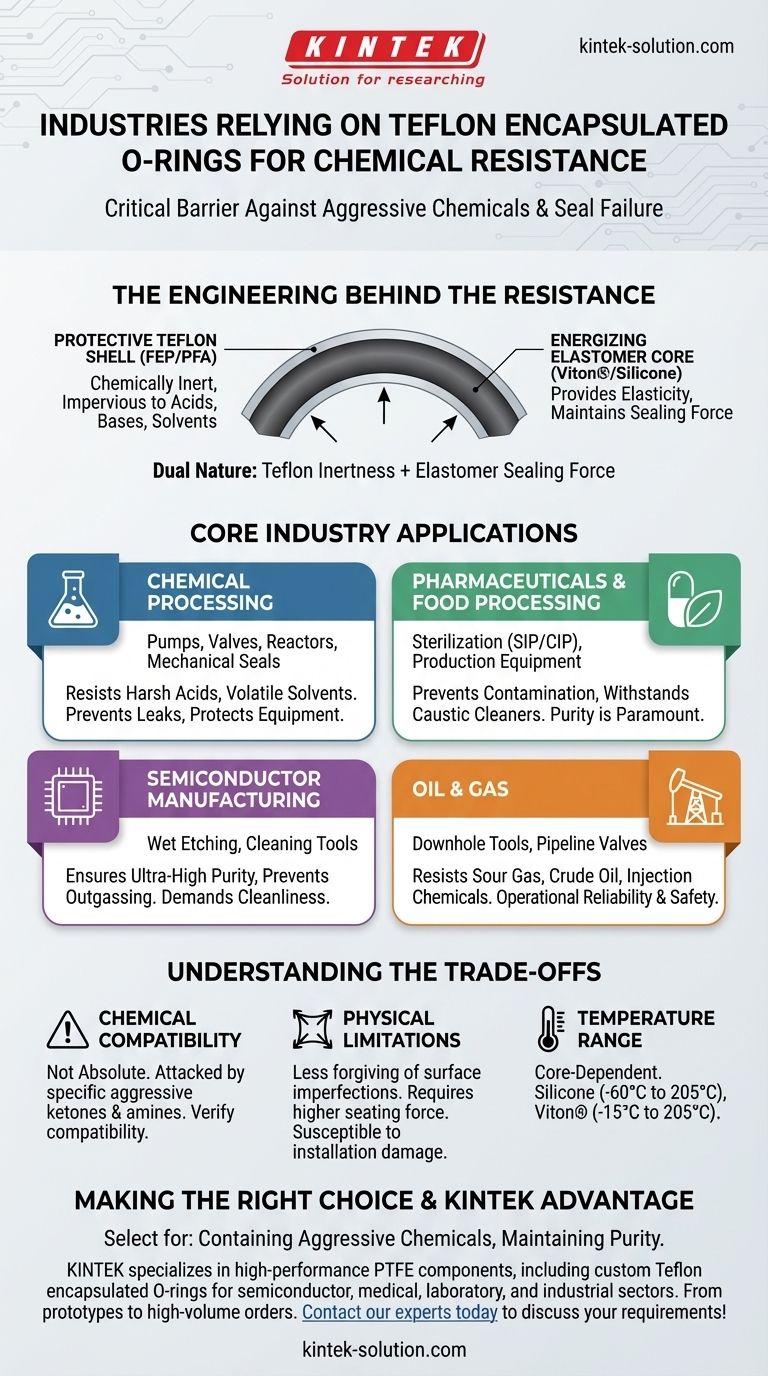

The Engineering Behind the Resistance

The value of these O-rings comes from their composite design. It's not just Teflon; it's a Teflon jacket over a traditional elastomer.

The Protective Teflon Shell

A thin, seamless layer of Teflon (often FEP or PFA) forms the outer shell. This is the component that comes into direct contact with the process media.

This shell is almost completely chemically inert, making it impervious to the vast majority of industrial chemicals, including strong acids, bases, and organic solvents.

The Energizing Elastomer Core

Inside the shell is a standard rubber O-ring, typically made of Viton® (FKM) or Silicone (VMQ). This core provides the elasticity and memory needed for the seal to function.

Without this core, a solid Teflon ring would be too rigid and suffer from poor compression set, leading to leaks. The core continuously pushes the shell outward, maintaining a tight, reliable seal.

Core Industry Applications

The unique properties of these seals make them indispensable in environments where both chemical purity and containment are non-negotiable.

Chemical Processing

This is the primary market. The O-rings are used in pumps, valves, reactors, and mechanical seals to handle everything from harsh acids to volatile solvents.

They prevent leaks, protect equipment from corrosion, and ensure process safety.

Pharmaceuticals & Food Processing

In these industries, purity is paramount. The Teflon encapsulation prevents the elastomer core from leaching into the product, avoiding contamination.

They also withstand aggressive steam-in-place (SIP) and clean-in-place (CIP) sterilization processes that use caustic cleaning agents.

Semiconductor Manufacturing

The fabrication of microchips involves extremely aggressive chemicals and demands ultra-high purity.

Teflon encapsulated O-rings are used in wet etching and cleaning equipment where any seal degradation or outgassing could ruin an entire batch of wafers.

Oil & Gas

From downhole drilling tools to pipeline valves, seals are exposed to a cocktail of corrosive chemicals, high pressures, and varying temperatures.

These O-rings provide the necessary resistance to sour gas, crude oil, and various injection chemicals, ensuring operational reliability and safety.

Understanding the Trade-offs

While exceptionally capable, Teflon encapsulated O-rings are not a universal solution. Understanding their limitations is critical for proper application.

Chemical Compatibility Isn't Absolute

Despite its broad resistance, the Teflon shell can be attacked by a few specific substances. Certain aggressive ketones and amines can degrade performance and should be avoided.

Always verify compatibility with the specific chemicals in your application.

Physical Limitations

The Teflon shell is more rigid than a standard elastomer. This means encapsulated O-rings are less forgiving of surface imperfections in the sealing gland.

They also require higher seating force to compress and can be more susceptible to damage during installation if not handled with care.

Temperature Range is Core-Dependent

The operational temperature range is dictated by the inner core material, not the Teflon shell.

A silicone core offers a wider temperature range (approx. -60°C to 205°C), while a Viton® core provides better compression set resistance but in a slightly narrower range (approx. -15°C to 205°C).

Making the Right Choice for Your Application

Selecting the correct seal requires matching its strengths to your primary operational challenge.

- If your primary focus is containing aggressive acids, solvents, or bases: These O-rings are likely the ideal choice due to the inert Teflon shell.

- If your primary focus is maintaining process purity: The encapsulation prevents leaching, making them a superior option for pharmaceutical, food, and semiconductor applications.

- If your application involves a highly dynamic or abrasive environment: Proceed with caution, as the Teflon jacket can be less durable than specialized elastomers designed for wear.

- If you are sealing in a low-pressure or vacuum system: Ensure you can achieve the necessary compression, as these seals are inherently stiffer than standard O-rings.

Ultimately, choosing a Teflon encapsulated O-ring is a strategic decision for when standard seals are guaranteed to fail.

Summary Table:

| Industry | Primary Application | Key Benefit |

|---|---|---|

| Chemical Processing | Pumps, Valves, Reactors | Resists harsh acids & solvents |

| Pharmaceuticals & Food | Sterilization Equipment (SIP/CIP) | Prevents contamination, withstands caustic cleaners |

| Semiconductor | Wet Etching & Cleaning Tools | Ensures ultra-high purity, prevents outgassing |

| Oil & Gas | Downhole Tools, Pipeline Valves | Resists sour gas, crude oil, and injection chemicals |

Need a reliable seal for aggressive chemicals?

KINTEK specializes in manufacturing high-performance PTFE components, including custom Teflon encapsulated O-rings. We serve the semiconductor, medical, laboratory, and industrial sectors by combining precision production with custom fabrication—from prototypes to high-volume orders.

Let us provide the sealing solution your critical application demands. Contact our experts today to discuss your requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech