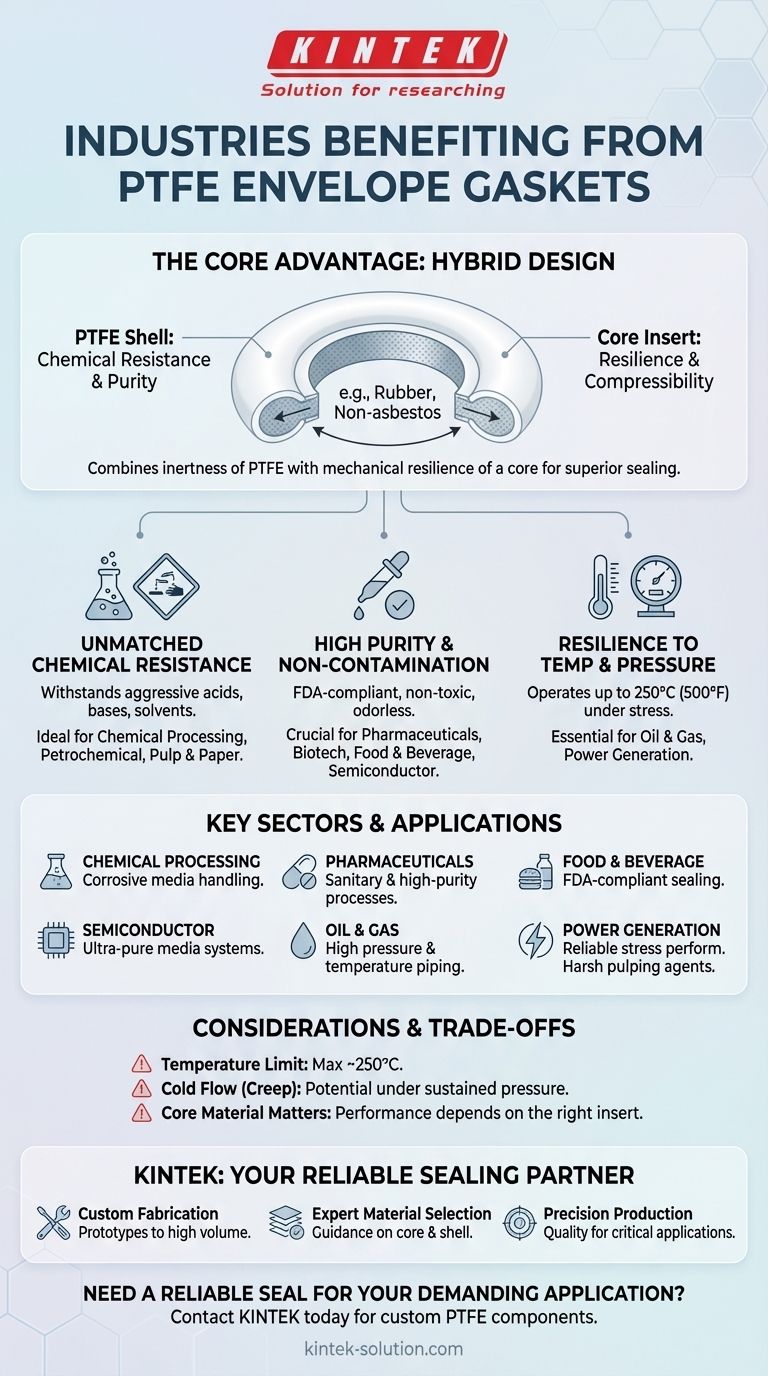

In short, PTFE envelope gaskets are critical in industries where equipment must withstand aggressive chemicals, maintain high purity, or handle significant temperature and pressure. Key sectors include chemical processing, pharmaceuticals, food and beverage, oil and gas, semiconductor manufacturing, and power generation.

The core value of a PTFE envelope gasket is its unique hybrid design. It combines the superior chemical inertness and purity of a PTFE shell with the mechanical resilience and compressibility of a core insert, solving sealing challenges that neither material could handle alone.

The Core Problem: Sealing in Hostile and Sensitive Environments

Many industrial processes require a perfect seal between two flange faces. The challenge is that the materials being processed are often highly corrosive, extremely hot, or cannot tolerate any contamination. This is where the specific properties of PTFE envelope gaskets become indispensable.

Unmatched Chemical Resistance

A primary benefit of PTFE is its remarkable inertness. It is resistant to nearly all industrial chemicals, including strong acids, bases, solvents, and other corrosive substances.

This property makes it the material of choice for the chemical processing, petrochemical, and pulp and paper industries, where harsh chemicals would quickly degrade standard sealing materials.

High Purity and Non-Contamination

PTFE is non-toxic, odorless, and recognized as a food-grade material suitable for FDA applications. It does not contaminate the media it comes into contact with.

This is a non-negotiable requirement for industries like pharmaceuticals, biotechnology, food and beverage, and semiconductor manufacturing, where even trace amounts of contamination can ruin an entire batch or process.

Resilience to Temperature and Pressure

PTFE envelope gaskets can operate effectively across a wide temperature range, typically up to 250°C (500°F), depending on the core material. They are engineered to withstand high pressure without breaking.

This durability makes them vital for demanding applications in power generation and oil and gas, where seals must remain stable and reliable under significant operational stress in piping systems, valves, and pressure vessels.

Understanding the Hybrid Design Advantage

The term "envelope" refers to the gasket's construction. It isn't a solid piece of PTFE but rather a composite design that leverages the strengths of multiple materials.

Combining Chemical and Mechanical Performance

A PTFE envelope gasket consists of a core insert material (like non-asbestos, rubber, or corrugated metal) that is encapsulated within a thin, protective "envelope" of PTFE.

This design delivers the best of both worlds: the compressibility and resilience of the core material provide a tight, durable seal, while the PTFE outer shell provides the necessary chemical and temperature resistance.

Adaptability to Different Flanges

This hybrid structure improves the gasket's ability to conform to flange surfaces, creating a better seal even on less-than-perfect faces.

It is particularly suitable for protecting fragile flanges, such as those that are glass-lined, where a hard gasket could cause chipping or cracking.

Common Pitfalls and Trade-offs

While highly effective, PTFE envelope gaskets are not a universal solution. Understanding their limitations is key to proper application and avoiding premature failure.

Absolute Temperature Limits

Although it has a wide operating range, PTFE has a definitive upper temperature limit of around 250°C (500°F). For applications exceeding this, alternative materials like graphite-filled spiral wound gaskets are typically required.

Potential for Cold Flow (Creep)

Under sustained high pressure and temperature, PTFE as a material can be susceptible to "creep" or "cold flow," where it slowly deforms over time. This can lead to a loss of bolt torque and potential leaks. The gasket's core insert is designed to mitigate this, but it remains a key consideration for long-term, high-stress applications.

The Importance of the Core Material

The overall performance of the gasket is heavily dependent on the insert material. Choosing the wrong core for your specific pressure, temperature, and media can lead to failure, even if the PTFE envelope itself remains intact.

Making the Right Choice for Your Application

Selecting the correct gasket requires balancing the need for chemical compatibility with the mechanical demands of the system.

- If your primary focus is purity and chemical resistance: PTFE envelope gaskets are an industry standard for handling aggressive or sensitive media in sanitary applications.

- If your primary focus is sealing fragile or glass-lined flanges: The compressibility of an envelope gasket with a soft core insert is the ideal choice to prevent flange damage.

- If your primary focus is extreme temperature (>250°C) and pressure: You should evaluate higher-rated options, such as spiral wound gaskets with graphite or other metallic fillers.

Ultimately, choosing the right gasket means understanding that its performance is a function of both its outer shell and its inner core.

Summary Table:

| Industry | Primary Benefit of PTFE Envelope Gasket |

|---|---|

| Chemical Processing | Unmatched resistance to corrosive acids, bases, and solvents. |

| Pharmaceuticals & Biotechnology | High purity, non-toxic, and non-contaminating for sensitive processes. |

| Food & Beverage | FDA-compliant, odorless, and suitable for sanitary applications. |

| Semiconductor Manufacturing | Prevents contamination in ultra-pure media handling systems. |

| Oil & Gas | Withstands high pressure and temperature in demanding piping systems. |

| Power Generation | Reliable performance under significant operational stress and temperature. |

| Pulp & Paper | Resists degradation from harsh chemical pulping agents. |

Need a Reliable Seal for Your Demanding Application?

PTFE envelope gaskets are engineered for performance in the most challenging environments. KINTEK specializes in the precision manufacturing of high-quality PTFE components, including custom envelope gaskets, for the semiconductor, medical, laboratory, and industrial sectors.

We understand that the right seal is critical to your process integrity, safety, and efficiency. Our expertise ensures you get a gasket that perfectly balances chemical resistance with mechanical resilience.

Let us provide the solution:

- Custom Fabrication: From prototypes to high-volume orders.

- Expert Material Selection: We help you choose the right core and shell for your specific temperature, pressure, and media.

- Precision Production: Quality you can rely on for critical applications.

Contact KINTEK today to discuss your sealing requirements and get a quote for custom PTFE components.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application