Future developments for Teflon-encapsulated O-rings are centered on two key areas: advancements in both the core and encapsulation materials and innovations in manufacturing processes. These evolutions are driven by increasing industry demands for sealing solutions that can perform reliably under more extreme chemical and temperature conditions, addressing the current limitations of the technology.

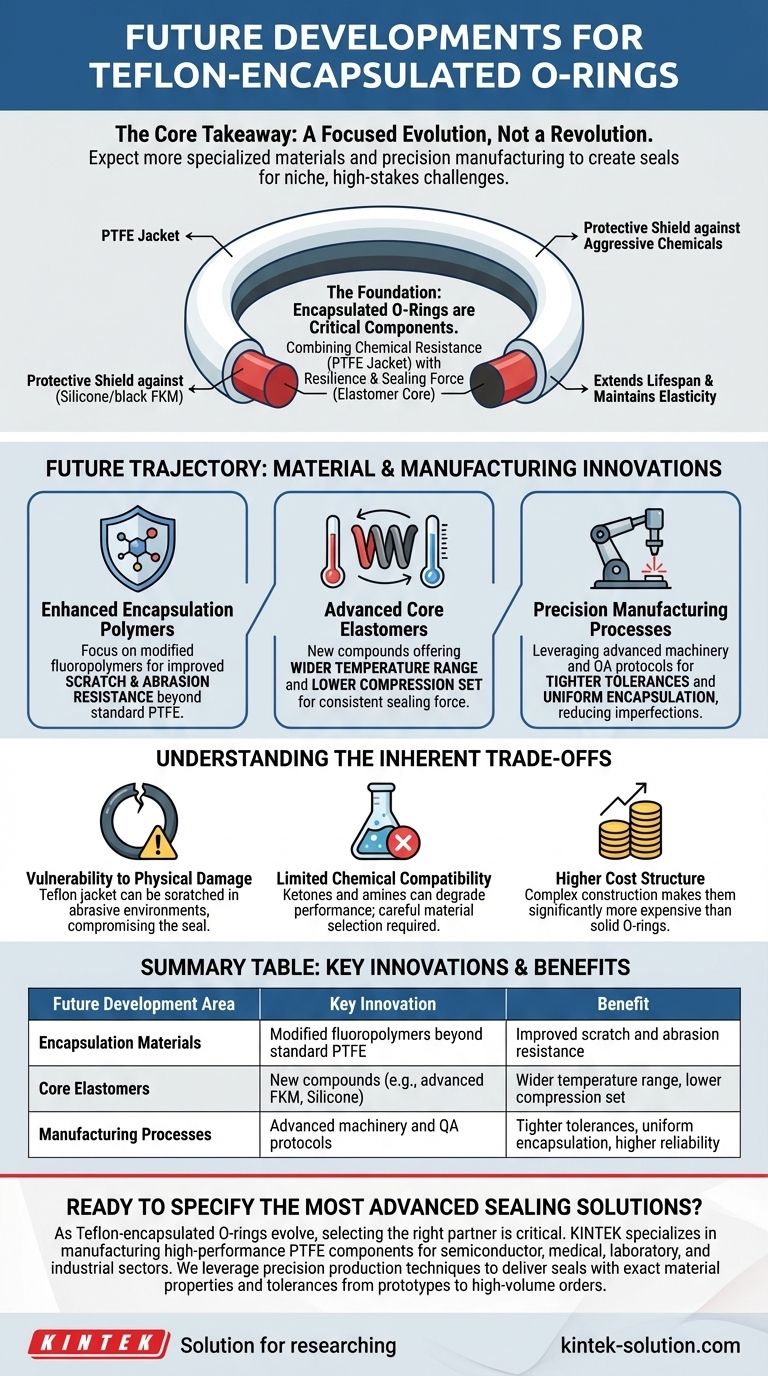

The core takeaway is that the future of encapsulated O-rings is not about a revolutionary redesign, but a focused evolution. Expect more specialized materials and precision manufacturing to create seals that solve niche, high-stakes challenges where both extreme chemical resistance and reliable elasticity are required.

The Foundation: Why Encapsulated O-Rings Are a Critical Component

Before looking forward, it's essential to understand the current design's purpose. Encapsulated O-rings solve a fundamental engineering conflict between chemical resistance and flexibility.

Combining the Best of Both Worlds

The design is a composite. It joins the superior chemical and temperature resistance of a PTFE (Teflon) jacket with the resilience and sealing force of an elastomeric core, typically made of Silicone or FKM (Viton).

A Protective, Functional Shield

This encapsulation protects the inner core from aggressive chemicals like acids, bases, and solvents. This extends the O-ring's lifespan and ensures it maintains its elasticity for an effective seal in demanding environments.

Future Trajectory: Material and Manufacturing Innovations

The references to "new materials and manufacturing processes" point directly to how these components will evolve to meet more specialized needs.

Enhanced Encapsulation Polymers

While Teflon (PTFE) is the standard, future developments will focus on modified fluoropolymers. The goal is to improve the jacket's resistance to scratching and abrasion—a known weakness of the current design.

Advanced Core Elastomers

Innovation will also occur within the core. Expect new elastomeric compounds that offer a wider operating temperature range or a lower compression set, providing more consistent sealing force over a longer period, especially in high-pressure or vacuum applications.

Precision Manufacturing Processes

Future manufacturing will leverage more advanced machinery and quality assurance protocols. This will result in O-rings with tighter tolerances, more uniform encapsulation, and a reduced risk of imperfections that could compromise seal integrity in critical systems.

Understanding the Inherent Trade-offs

To appreciate future developments, you must acknowledge the current limitations of the technology. These are the problems that innovation seeks to solve.

Vulnerability to Physical Damage

The Teflon jacket is relatively soft and can be scratched or damaged in abrasive environments. Any breach in the jacket compromises the seal by exposing the less-resistant core.

Limited Chemical Compatibility

While excellent, the chemical resistance is not absolute. Certain ketones and amines are known to degrade the performance of the encapsulation, requiring careful material selection for specific applications.

Higher Cost Structure

The complex, multi-material construction makes encapsulated O-rings significantly more expensive than solid elastomer or solid Teflon O-rings. This cost is a primary consideration in any application.

Making the Right Choice for Your Application

Understanding the trajectory of this technology helps you make better decisions today while planning for the future.

- If your primary focus is balanced performance: An encapsulated O-ring is the premier choice when you need both the chemical inertness of PTFE and the reliable sealing force of an elastomer.

- If your application involves abrasive media: Proceed with caution and investigate emerging encapsulation materials specifically designed for enhanced scratch resistance.

- If you are navigating extreme chemical environments: Always verify compatibility, paying special attention to ketones and amines, and consult material guides for the specific grade of encapsulation.

Ultimately, staying aware of these material and manufacturing advancements will empower you to select more durable and reliable sealing solutions for your most critical designs.

Summary Table:

| Future Development Area | Key Innovation | Benefit |

|---|---|---|

| Encapsulation Materials | Modified fluoropolymers beyond standard PTFE | Improved scratch and abrasion resistance |

| Core Elastomers | New compounds (e.g., advanced FKM, Silicone) | Wider temperature range, lower compression set |

| Manufacturing Processes | Advanced machinery and QA protocols | Tighter tolerances, uniform encapsulation, higher reliability |

Ready to Specify the Most Advanced Sealing Solutions?

As Teflon-encapsulated O-rings evolve to meet extreme demands in chemical resistance, temperature, and pressure, selecting the right partner for custom fabrication is critical. KINTEK specializes in manufacturing high-performance PTFE components, including custom encapsulated O-rings, for the semiconductor, medical, laboratory, and industrial sectors.

We leverage precision production techniques to deliver seals with the exact material properties and tolerances your application requires—from prototypes to high-volume orders. Ensure your critical systems are equipped with the most reliable sealing technology available.

Contact KINTEK today to discuss your specific needs and get a quote for your next project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments