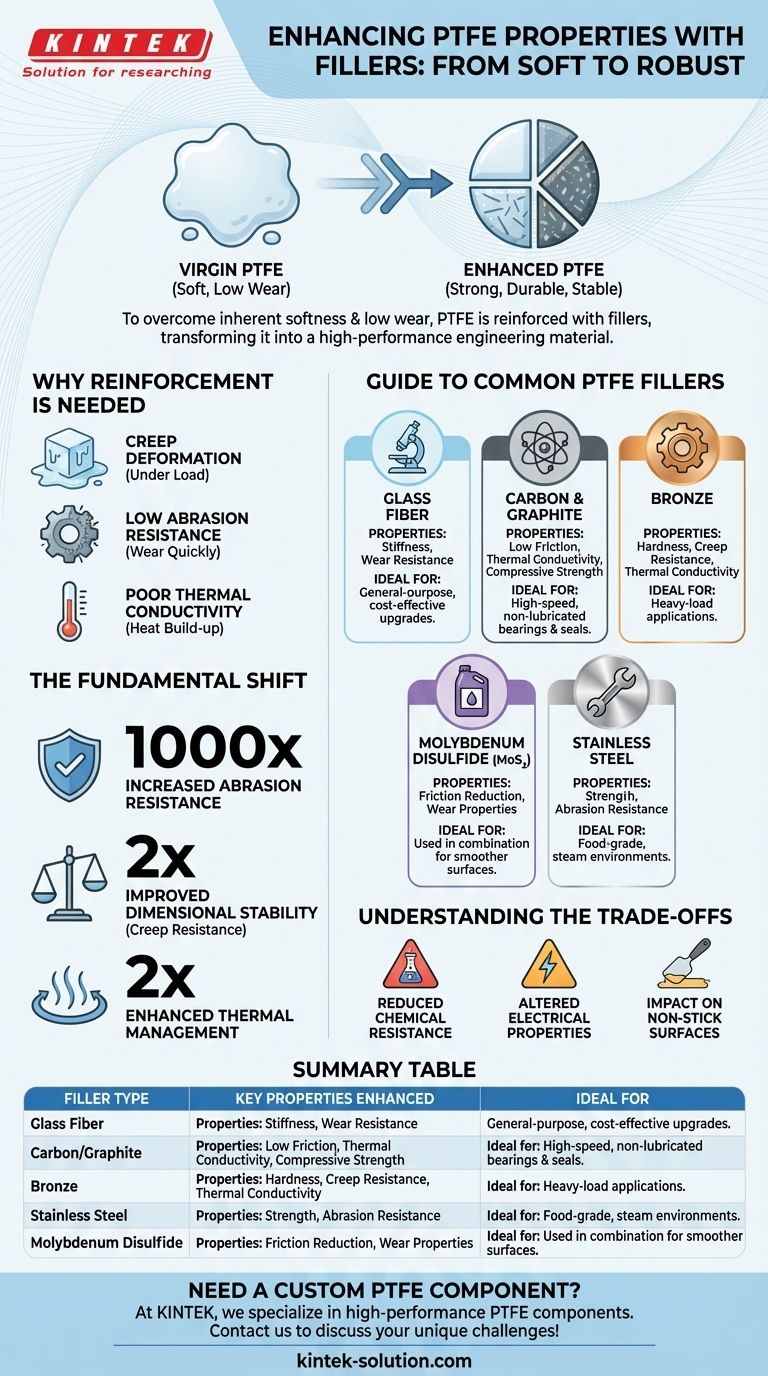

To overcome its inherent softness and low wear resistance, Polytetrafluoroethylene (PTFE) is commonly enhanced with fillers like glass fiber, carbon, graphite, bronze, stainless steel, and molybdenum disulfide. These additives are not mere additions; they fundamentally transform PTFE into a high-performance engineering material by dramatically improving its mechanical strength, resistance to wear and creep, and thermal conductivity.

The core challenge with virgin PTFE is its tendency to deform under load and wear quickly in dynamic applications. Fillers solve this by creating a composite material that retains PTFE's low friction while gaining the structural integrity it naturally lacks.

Why Virgin PTFE Needs Reinforcement

While known for its extreme chemical resistance and low-friction surface, pure PTFE has significant mechanical limitations that make it unsuitable for many demanding applications.

The Challenge of "Creep"

Virgin PTFE is a relatively soft material. When subjected to a sustained load, especially at elevated temperatures, it will slowly deform or "creep," losing its original shape and compromising seal integrity or component tolerances.

Low Abrasion Resistance

In applications involving moving parts, such as bearings or seals, unfilled PTFE wears down quickly. Its excellent slip properties do not translate to durability against abrasive forces.

Poor Thermal Conductivity

PTFE is an excellent thermal insulator. In high-speed applications, friction generates heat that cannot dissipate effectively, which can cause the material to expand and fail prematurely.

How Fillers Fundamentally Change PTFE

Introducing fillers creates a composite material with vastly superior engineering properties. The improvements are not incremental; they represent a fundamental shift in performance.

A Massive Leap in Durability

Adding fillers can increase the abrasion resistance of PTFE by a factor of 1000 times compared to its virgin state. The filler particles provide a hard structural matrix that protects the softer PTFE from wear.

Improved Dimensional Stability

Filled PTFE grades can offer twice the creep resistance of unfilled versions. The fillers act as a reinforcing skeleton, helping the material maintain its shape under heavy, continuous loads.

Enhanced Thermal Management

Fillers significantly improve heat transfer, with some filled grades exhibiting twice the thermal conductivity. This allows frictional heat to dissipate away from the contact surface, maintaining stability in high-speed applications.

A Guide to Common PTFE Fillers

Each filler imparts a unique set of properties, allowing PTFE to be tailored for specific operational environments.

Glass Fiber

Glass is the most common filler, providing an excellent all-around enhancement of properties. It dramatically improves stiffness and wear resistance and has good chemical resistance, except against strong alkalis and hydrofluoric acid.

Carbon & Graphite

Carbon enhances compressive strength, hardness, and creep resistance. Graphite is often added alongside carbon to create a compound with an extremely low coefficient of friction, making it ideal for non-lubricated, high-speed dynamic applications.

Bronze

Bronze provides the best performance in terms of wear resistance and thermal conductivity. It significantly increases hardness and compressive strength, making it suitable for heavy-load applications.

Molybdenum Disulfide (MoS₂)

Often used in combination with other fillers, MoS₂ is a dry lubricant that further reduces friction and improves wear properties. It creates a harder, smoother, and more durable surface.

Stainless Steel

This filler is used to increase strength and abrasion resistance, especially in applications requiring food-grade materials or those involving steam. It provides excellent hardness and wear characteristics.

Understanding the Trade-offs

Enhancing PTFE with fillers is a strategic compromise. While mechanical properties are vastly improved, some of PTFE's inherent advantages can be diminished.

Reduced Chemical Resistance

Fillers like glass and bronze do not share virgin PTFE's near-total chemical inertness. They can be attacked by certain chemicals, which must be considered during material selection.

Altered Electrical Properties

Virgin PTFE is an excellent electrical insulator. The addition of carbon or metallic fillers can make the material electrically conductive, which may be undesirable for certain applications.

Impact on Non-Stick Surfaces

The inclusion of filler particles can slightly compromise the exceptionally non-stick and anti-adhesive surface of pure PTFE, though the low-friction properties generally remain excellent.

Selecting the Right Filled PTFE for Your Application

The choice of filler should be directly driven by the primary demand of your application.

- If your primary focus is general-purpose wear resistance and stiffness: Glass-filled PTFE offers a balanced and cost-effective performance upgrade.

- If your primary focus is high-speed, non-lubricated motion: Carbon/graphite-filled PTFE provides the low friction and thermal dissipation required for bearings and seals.

- If your primary focus is maximum hardness under heavy loads: Bronze-filled PTFE delivers the best wear resistance and dimensional stability, provided chemical compatibility is not an issue.

- If your primary focus is food-grade or steam environments: Stainless steel-filled PTFE offers excellent strength, durability, and cleanability.

By choosing the correct filler, you transform PTFE from a simple low-friction polymer into a robust engineering component tailored to its specific task.

Summary Table:

| Filler Type | Key Properties Enhanced | Ideal For |

|---|---|---|

| Glass Fiber | Stiffness, Wear Resistance | General-purpose, cost-effective upgrades |

| Carbon/Graphite | Low Friction, Thermal Conductivity | High-speed, non-lubricated bearings & seals |

| Bronze | Hardness, Creep Resistance | Heavy-load applications |

| Stainless Steel | Strength, Abrasion Resistance | Food-grade, steam environments |

| Molybdenum Disulfide | Friction Reduction, Wear Properties | Used in combination for smoother surfaces |

Need a custom PTFE component that stands up to your specific demands?

At KINTEK, we specialize in manufacturing high-performance PTFE components—from seals and liners to custom labware—enhanced with the right fillers for your industry. Whether you're in semiconductor, medical, laboratory, or industrial sectors, our precision production and custom fabrication (from prototypes to high-volume orders) ensure your PTFE parts deliver maximum durability, wear resistance, and thermal management.

Contact us today to discuss how our filled PTFE solutions can solve your unique engineering challenges!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support